Large efficient remote control compressor for oil exploitation

A remote control, compressor technology, applied in pump control, production of fluids, mechanical equipment, etc., can solve the problems of inconvenient maintenance, unfavorable compressor stay and fixed, complicated compressor installation, etc., to achieve the effect of ensuring stability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

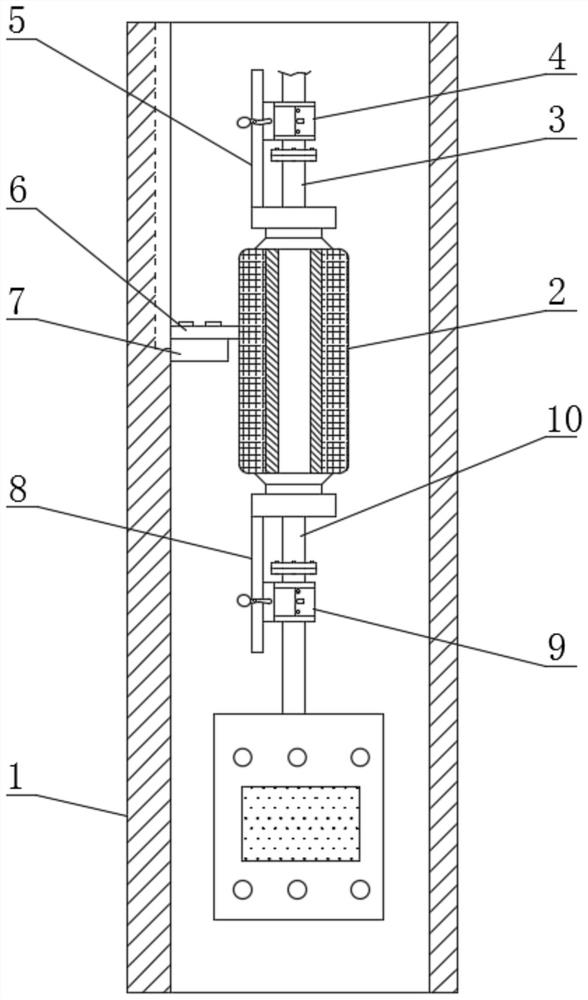

[0041] Embodiment one, with reference to Figure 1-4, a large-scale high-efficiency remote-controlled compressor for oil development, including a drill collar 1, characterized in that a compressor 2 is installed inside the drill collar 1, and an air inlet pipe 3 is arranged at one end of the compressor 2, and the air inlet pipe 3, a first support plate 5 is arranged below, and a first fixing mechanism 4 is installed on the top surface of the first support plate 5, and an exhaust pipe 10 is arranged at the other end of the compressor 2, and an exhaust pipe 10 is arranged under the exhaust pipe 10. The second support plate 8, the top surface of the second support plate 8 is provided with a second fixing mechanism 9, and the inside of the first fixing mechanism 4 and the second fixing mechanism 9 is provided with a first arc-shaped fixing plate 11 and a second arc-shaped fixing plate 11. shaped fixing plate 27, the top surface of the first arc-shaped fixing plate 11 is provided w...

Embodiment 2

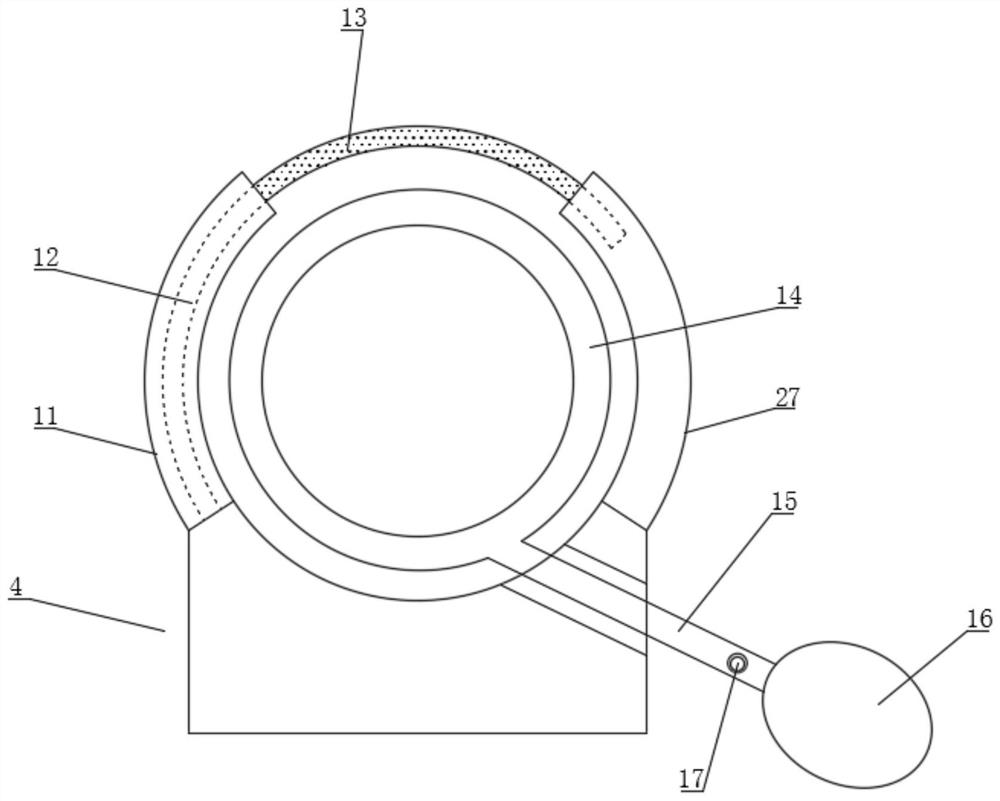

[0042] Embodiment two, refer to figure 1 , 2 and Figure 5 , the inside of the first fixing mechanism 4 and the second fixing mechanism 9 is provided with an extruding mechanism 14, and the inside of the extruding mechanism 14 is provided with an air bag, and one end of the air bag is connected with a pipe 15, and one end of the pipe 15 is provided with a pressing Ball 16, the surface of the pipeline 15 is provided with an air release valve 17, the airbag is a hollow cylindrical structure, the outer wall surface of the airbag is provided with a second extrusion protrusion 23, and the inner wall surface of the airbag is provided with a first extrusion convex grain 22, the first extrusion convex grain 22 and the second extrusion convex grain 23 are equidistantly arranged on the inner wall surface and the outer wall surface of the airbag, by setting the extrusion mechanism 14, the extrusion mechanism 14 is composed of the airbag, and the airbag is Hollow cylindrical structure, ...

Embodiment 3

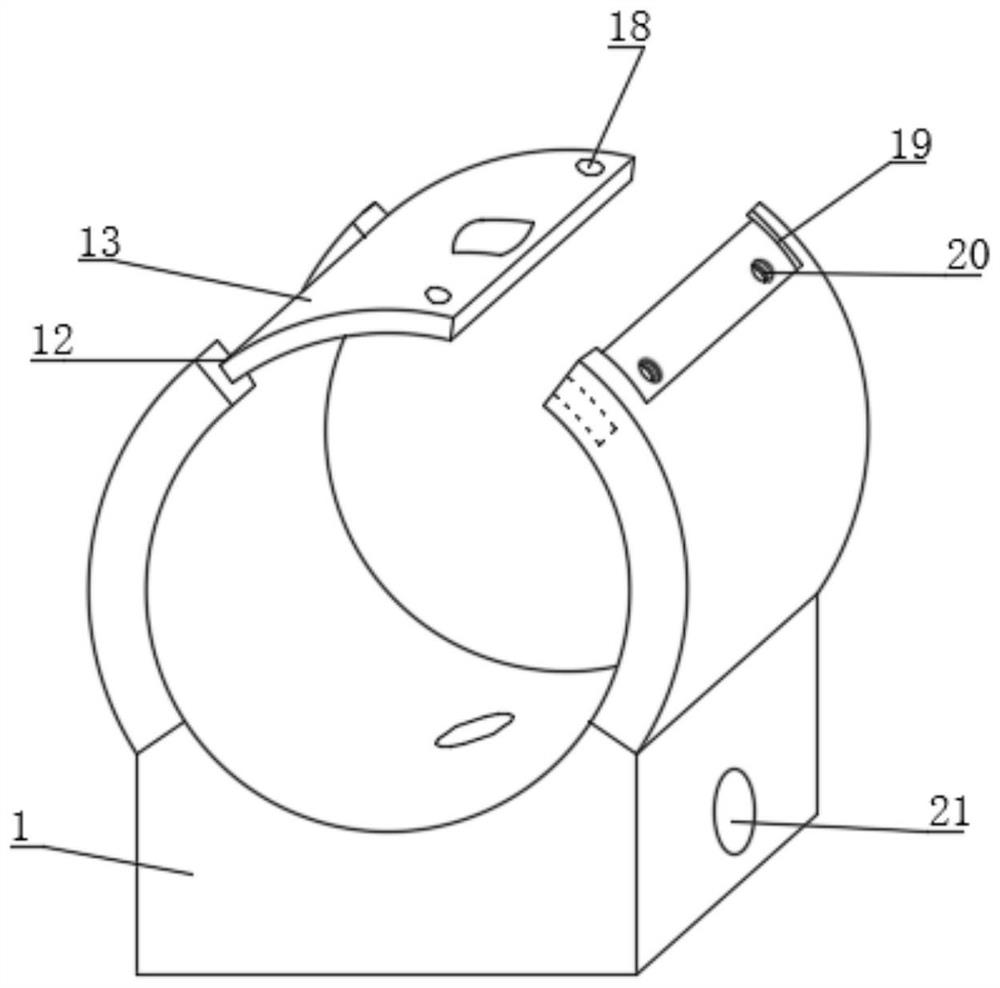

[0043] Embodiment three, refer to figure 1 , 6 and Figure 7 , the surface of the inner wall of the drill collar 1 is provided with a mounting block 7, the outer surface of the compressor 2 is provided with a mounting plate 6, and the surface of the mounting plate 6 and the surface of the mounting block 7 is provided with a mounting hole 25, and the mounting plate 6 is passed through the tight The firmware penetrates the mounting hole 25 and is fixed to the mounting block 7. The inner wall surface of the drill collar 1 is symmetrically provided with a slide rail 24, and one end of the mounting plate 6 is provided with a slide block 26, and the slide block 26 is slidably connected to the slide rail 24. When fixing the compressor 2, the compressor 2 slides with the slide rail 24 through the slider 26 at the end of the installation plate 6, thereby moving to the surface of the installation block 7 through the cooperation of the slider 26 and the slide rail 24, and then fixing it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com