Safety cable bridge

A cable bridge and safety technology, applied in the direction of electrical components, etc., can solve the problems of inconvenient cable maintenance, inability to make safe response actions, poor safety, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

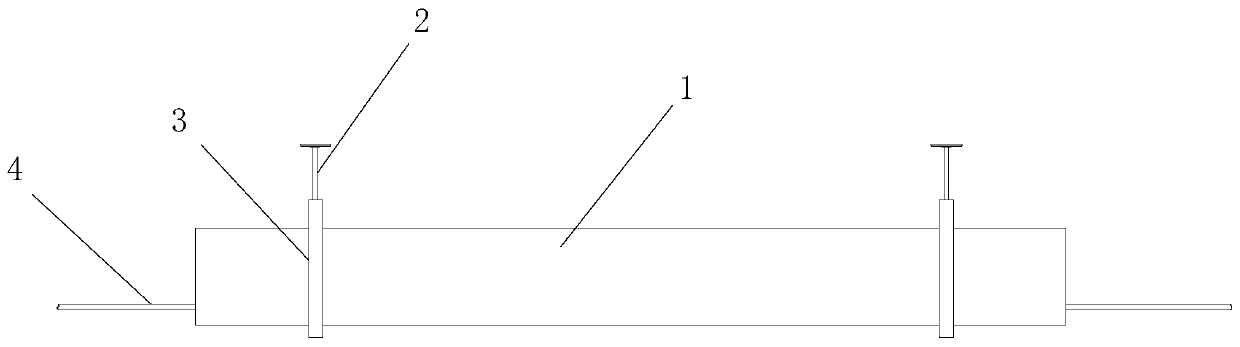

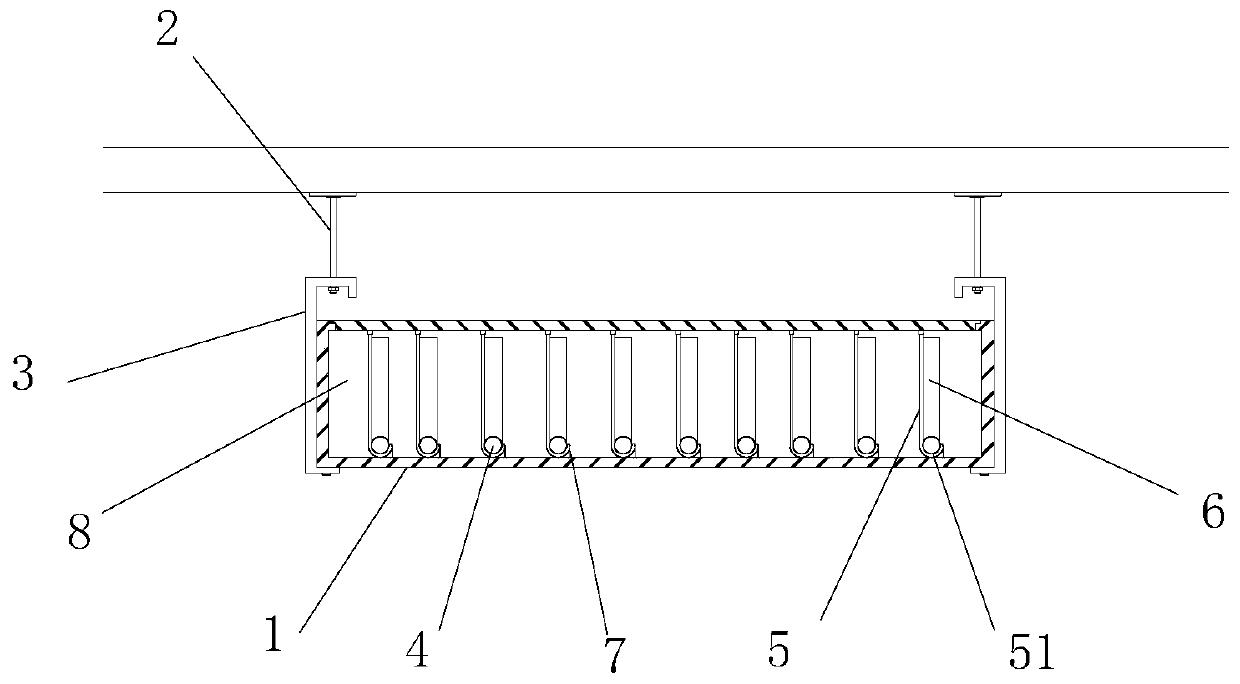

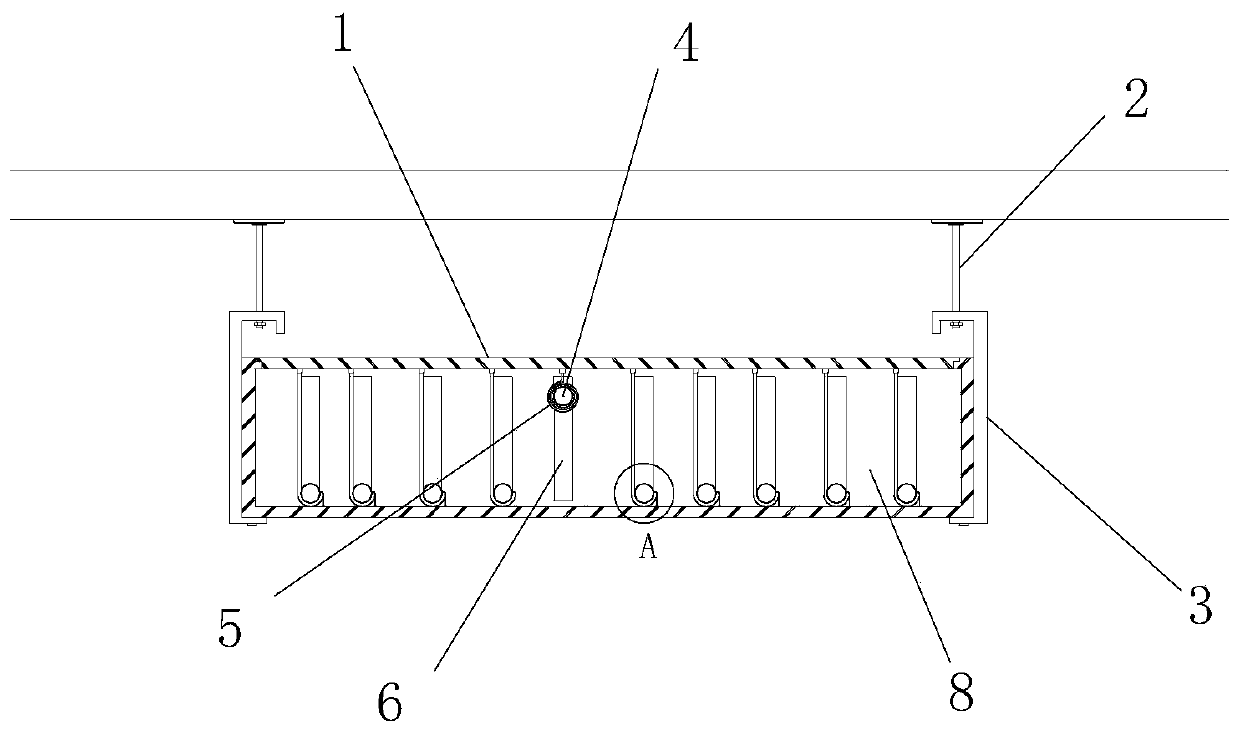

[0018] Such as figure 1 and figure 2 As shown, the safety cable tray includes a cable tray main body 1, which has a sealed installation cavity 8 inside the cable tray main body 1, and a plurality of chutes 6 communicating with the installation cavity are provided on both sides of the cable tray main body 1, each The bar chute 6 extends upwards from the bottom, and the cable 4 is set through the chute 6 on the main body 1 of the cable tray;

[0019] The cables 4 are arranged in the chute 6 on both sides and pass through the entire installation cavity 8. In the installation cavity 8, more than one partition 5 is arranged along the width direction of the cable tray main body 1. Each partition 5 corresponds to a cable. 4. The top of the partition 5 is fixedly connected to the main body of the cable tray 1, the bottom of the partition 5 is an active surface, and the bottom movable surface of the partition 5 forms an arc-shaped winding part 51, and the cable 4 is arranged on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com