Optical gate protection circuit for light conducting system of laser processing equipment

A light guide system and laser processing technology, applied in circuits, lasers, laser parts, etc., can solve the problems of poor reliability, complicated adjustment, and cumbersome work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

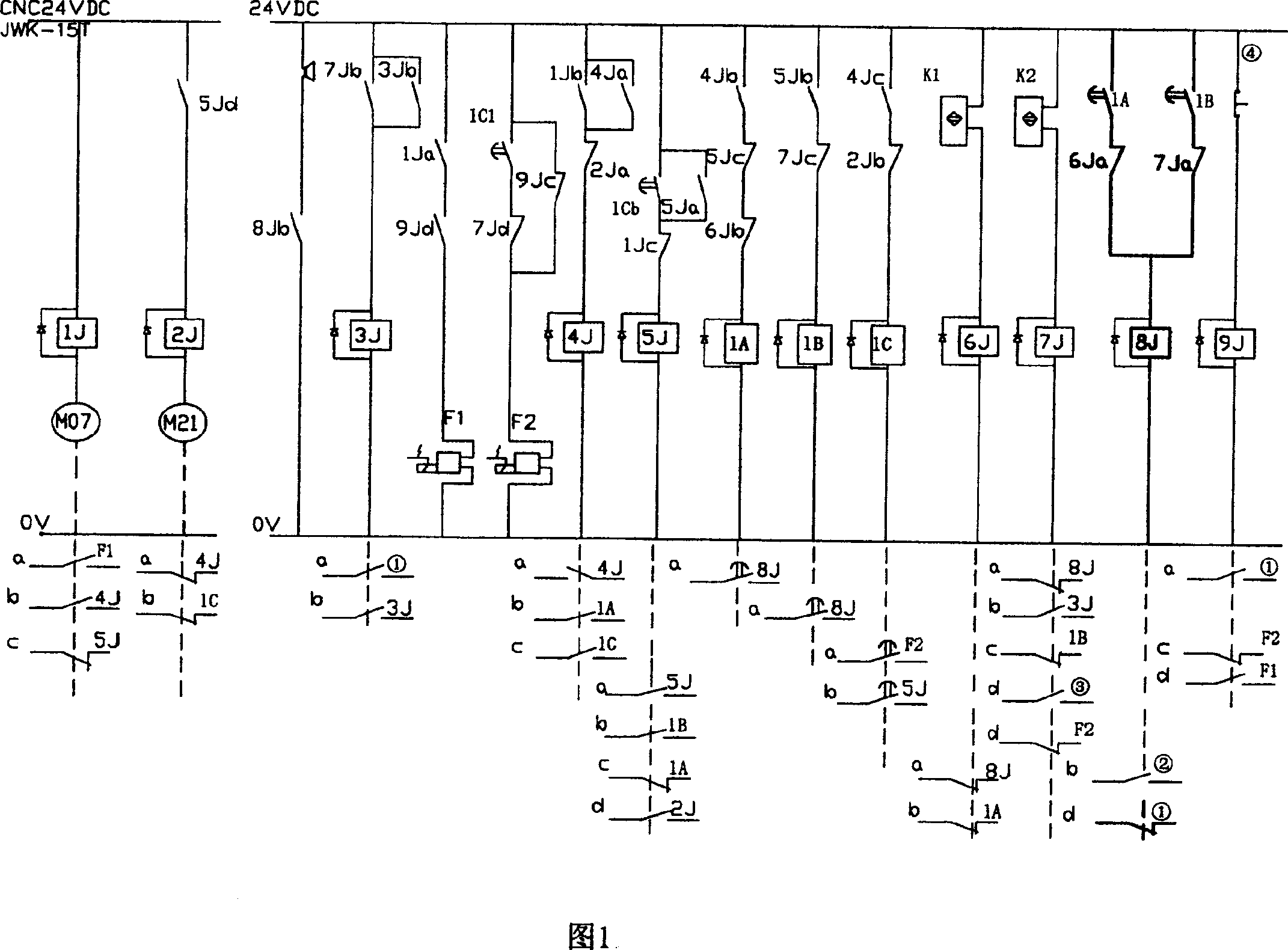

[0008] Combined with the accompanying drawings below, and use the 1500W, wavelength 10.6μCO for processing an automobile part 2 Taking a laser as an example, the optical gate protection circuit of the present invention will be described in detail.

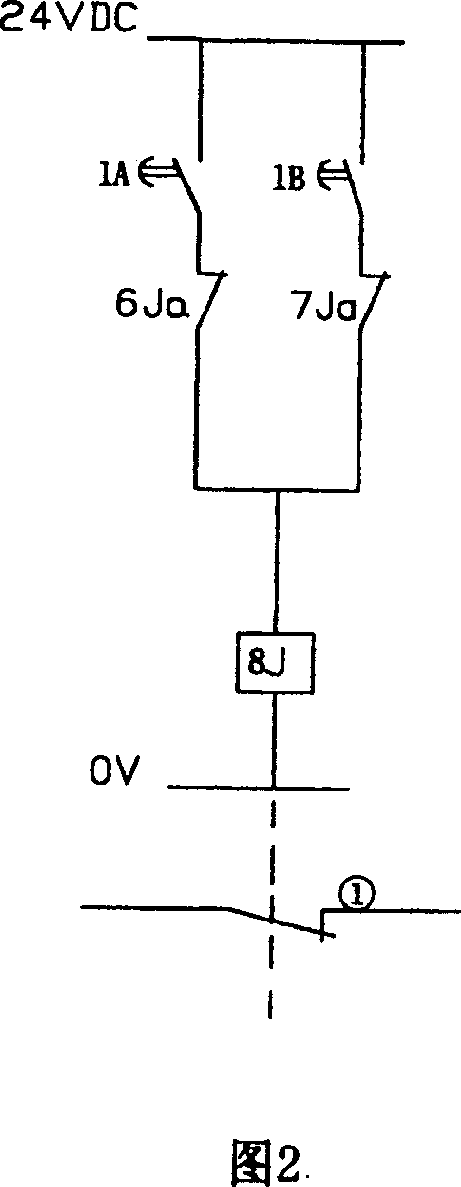

[0009] As shown in Figure 1 and Figure 2, the light gate protection circuit of the laser processing equipment light guide system of the present invention is mainly composed of a delay relay 1A, a delay relay 1B, a first common relay 6J, a second common relay 7J, and a relay 8J. The normally open contact of delay relay 1A is connected in series with the normally closed contact 6Ja of the first common relay 6J; the normally open contact of another time delay relay 1B is connected in series with the normally closed contact 7Ja of the second common relay 7J; The above two series circuits are connected in parallel and connected in series with relay 8J; the other end of relay 8J is connected with 0V line, and the other end of delay relay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com