Apparatus and method for use with robot

A technology of robots and grippers, applied in the field of robot devices, can solve problems such as difficult precise positioning of grippers, and achieve fast and accurate calibration or teaching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles of the disclosure will now be described with reference to several example embodiments illustrated in the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the description of the embodiments is merely to help those skilled in the art better understand and thus implement the present disclosure, and not to limit the scope of the present disclosure in any way. .

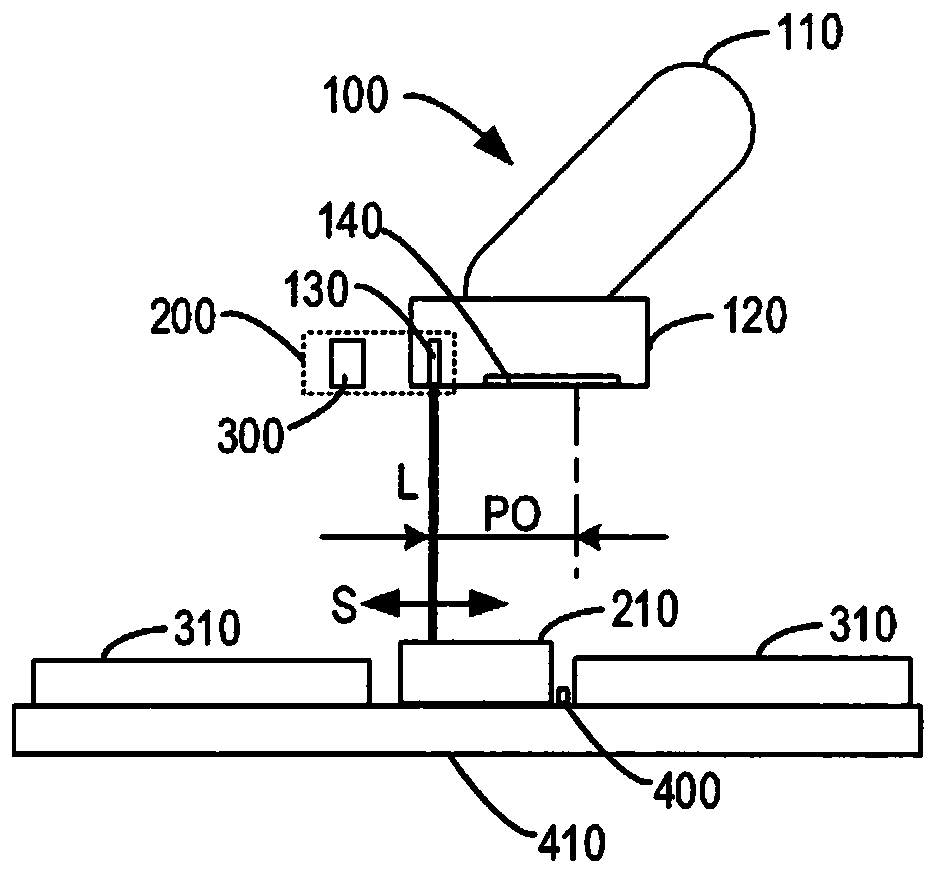

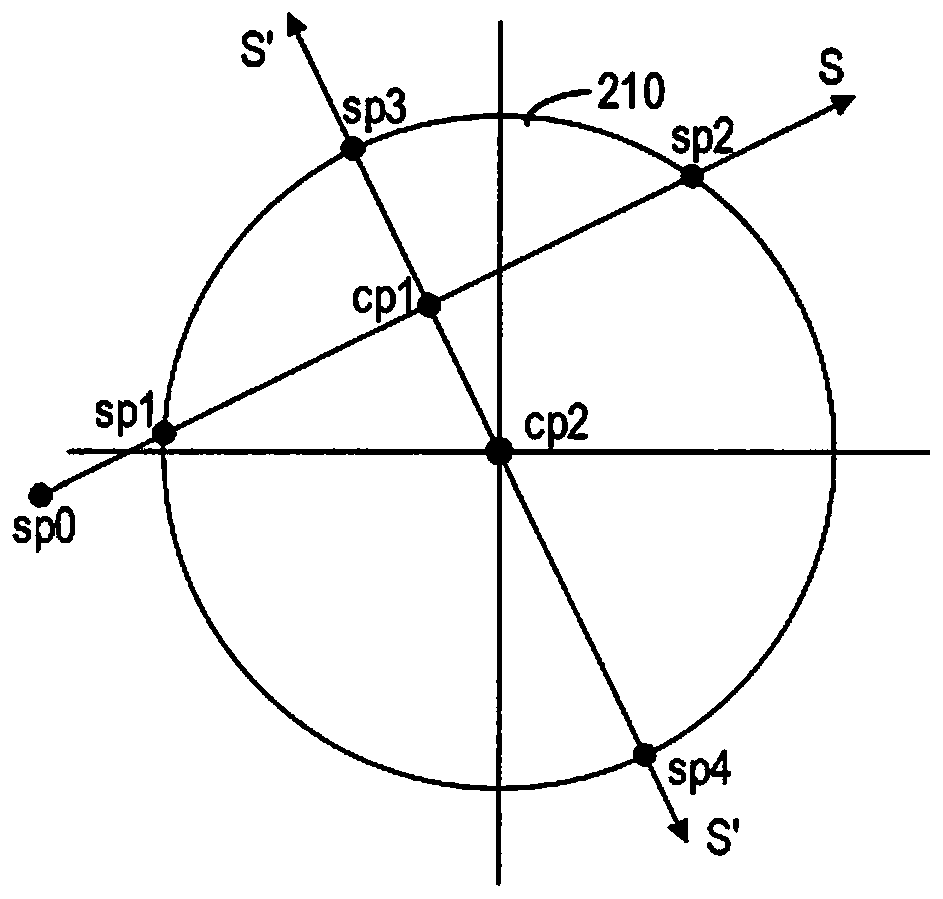

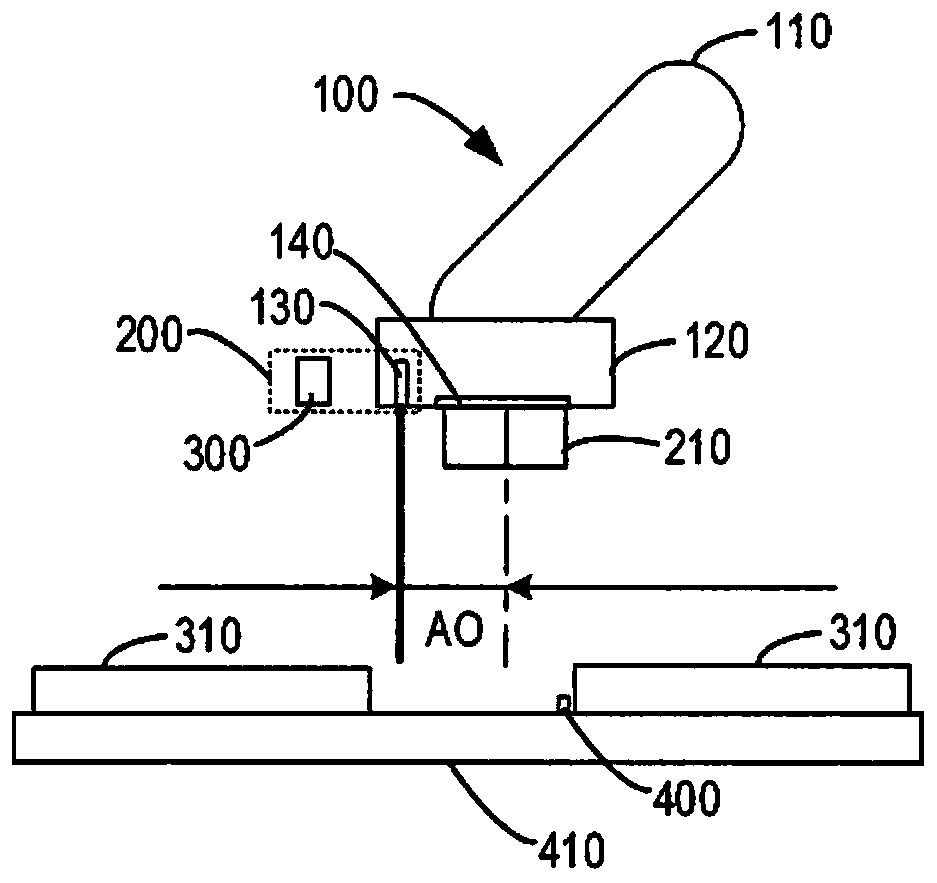

[0040] figure 1A scanning motion of an apparatus 200 for a robot 100 over a target object 210 is schematically shown according to some example embodiments. As shown, the target object 210 is supplied onto and supported by the table 410 by the feeder 310 . The robot 100 includes a robot arm 110 and a gripper 120 connected to the robot arm 110 . The gripper 120 is driven by the robot arm 110 to move between different positions above the table 410 . Gripper 120 includes a gripping member 140 operable to grip and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com