A kind of polymer powder material

A technology of high molecular polymer and powder materials, applied in the field of additive manufacturing, can solve the problems of color deterioration, long cooling time and short service life of parts, and achieve excellent melt fluidity, suitable melting temperature, high melt The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

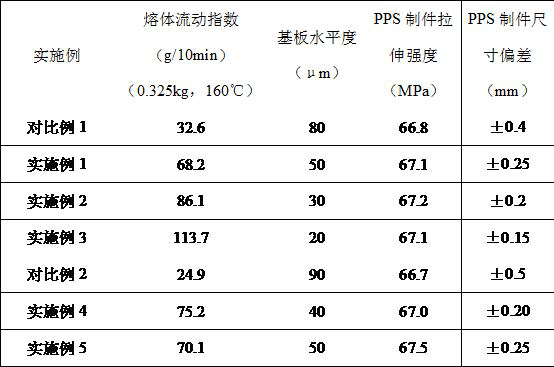

Embodiment 1

[0025] Weigh polyamide copolymer powder (Amilan® CM8000, particle size less than 500μm): 1.82kg, epoxy plastic powder (Xinxi Chemical SH-E50, particle size less than 500μm): 0.06kg, calcium stearate (Hongyuan Chemical industry, particle size less than 500μm): 0.12kg, use the mixing process of stirring rate 200RPM, stirring time 60min to mix the components evenly, test the melt flow index of the material, and then spread it on the substrate to heat and melt, natural leveling, After cooling, test the levelness of the leveling layer, and then print PPS material on the leveling layer at a temperature of 60°C to test its mechanical properties and dimensional accuracy.

Embodiment 2

[0027] Weigh polyamide copolymer powder (Amilan® CM8000, particle size less than 500μm): 1.7kg, epoxy plastic powder (Xinxi Chemical SH-E50, particle size less than 500μm): 0.06kg, calcium stearate (Hongyuan Chemical industry, particle size less than 500μm): 0.24kg, use the mixing process of stirring rate 200RPM, stirring time 60min to mix the components evenly, test the melt flow index of the material, and then spread it on the substrate to heat and melt, natural leveling, After cooling, test the levelness of the leveling layer, and then print PPS material on the leveling layer at a temperature of 60°C to test its mechanical properties and dimensional accuracy.

Embodiment 3

[0029] Weigh polyamide copolymer powder (Amilan® CM8000, particle size less than 500μm): 1.52kg, epoxy plastic powder (Xinxi Chemical SH-E50, particle size less than 500μm): 0.06kg, calcium stearate (Hongyuan Chemical industry, particle size less than 500μm): 0.42kg, using a mixing process with a stirring rate of 200RPM and a stirring time of 60min to mix the components evenly, test the melt flow index of the material, and then spread it on the substrate to heat and melt, natural leveling, After cooling, test the levelness of the leveling layer, and then print PPS material on the leveling layer at a temperature of 60°C to test its mechanical properties and dimensional accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com