Pigment dispersing agent, pigment composition, and pigment coloring agent

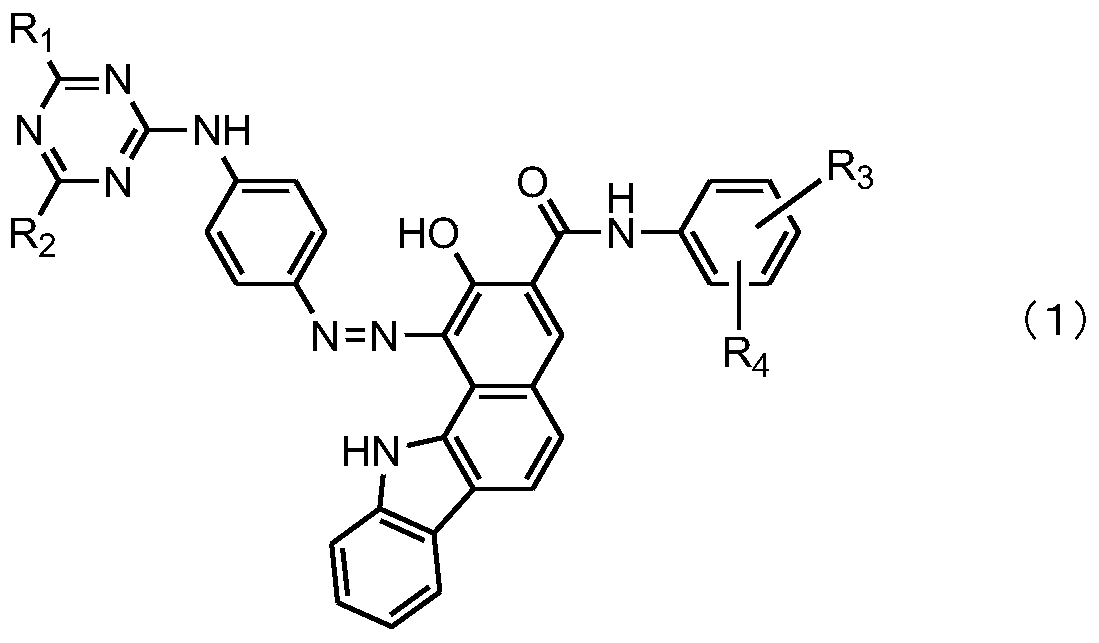

A pigment dispersant and pigment technology, used in the fields of pigment dispersants, pigment compositions and pigment colorants, can solve the problems of reduced gloss of the coating film, increased viscosity of the binder, insufficient optical density, etc., and achieve the effect of inhibiting aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

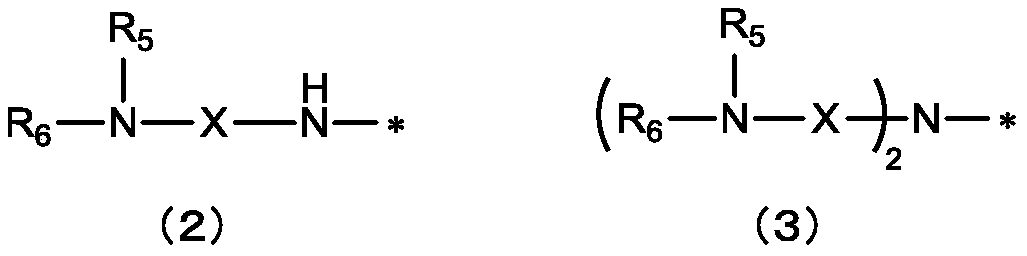

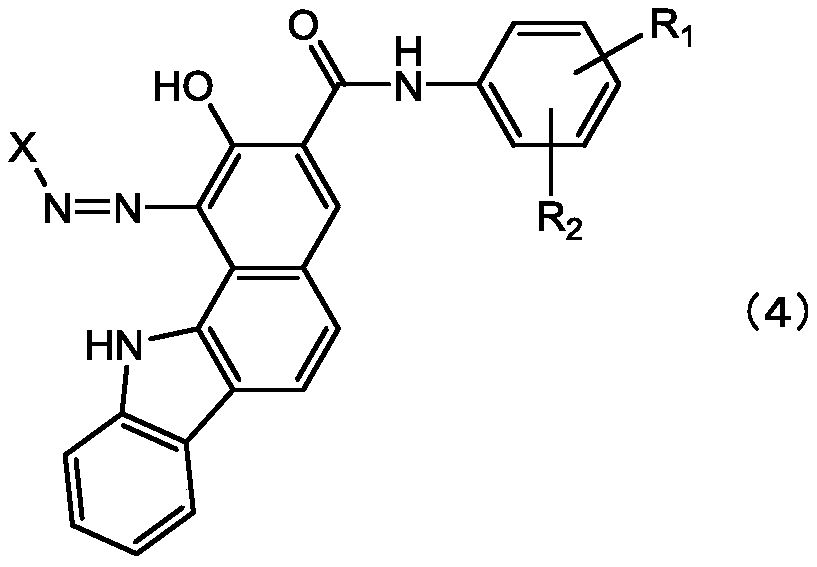

Method used

Image

Examples

Embodiment 1-1

[0120] 14.8 parts of cyanuric chloride, 12 parts of 4'-aminoacetanilide, and 9.6 parts of acetic acid were added to 100 parts of water, and reacted at 0 to 10°C for 1 hour. After adding 24.5 parts of N,N-dimethylaminopropylamine and reacting at 70 to 80° C. for 2 hours, 33 parts of concentrated hydrochloric acid were further added. After reacting at 90-100° C. for 1 hour for deacetylation, cool to 0-10° C., add 6 parts of sodium nitrite, carry out diazotization, and obtain a solution of diazonium salt. On the other hand, 30.5 parts of N-(4-methoxyphenyl)-2-hydroxy-11H-benzo[a]carbazole-3-carboxamide and 26 parts of sodium hydroxide were dissolved in 800 parts of methanol to prepare solution. The diazonium salt solution was added to the prepared solution, and the coupling reaction was carried out at 20-30° C. for 5 hours. After filtering and washing with water, it dried and obtained 49 parts of blue-violet pigment dispersants (A) represented by following formula (A).

[0121...

Embodiment 1-2

[0124] Except that 31 parts of N,N-diethylaminopropylamine was used instead of 24.5 parts of N,N-dimethylaminopropylamine, the blue color represented by the following formula (B) was obtained in the same manner as in Example 1-1 above. Purple pigment dispersant (B) 53 parts.

[0125]

[0126] A peak with a molecular weight of 837.05 was detected by mass spectrometry using MALDI. In addition, the purity measured by high performance liquid chromatography was 91%. From the raw materials used, the results of mass spectrometry and the results of high performance liquid chromatography, it was confirmed that the compound of the target structure was obtained.

Embodiment 1-3

[0128] Except that 45 parts of N,N-dibutylaminopropylamine was used instead of 24.5 parts of N,N-dimethylaminopropylamine, the blue color represented by the following formula (C) was obtained in the same manner as in Example 1-1 above. Purple pigment dispersant (C) 61 parts.

[0129]

[0130] A peak with a molecular weight of 949.27 was detected by mass spectrometry using MALDI. In addition, the purity measured by high performance liquid chromatography was 92%. From the raw materials used, the results of mass spectrometry and the results of high performance liquid chromatography, it was confirmed that the compound of the target structure was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com