Adhesive based mounting structure

A technology for installing structures and adhesives, applied in the direction of connecting components, material gluing, suction cups, etc., can solve the problems of reducing the optimal bonding strength and excessive use of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

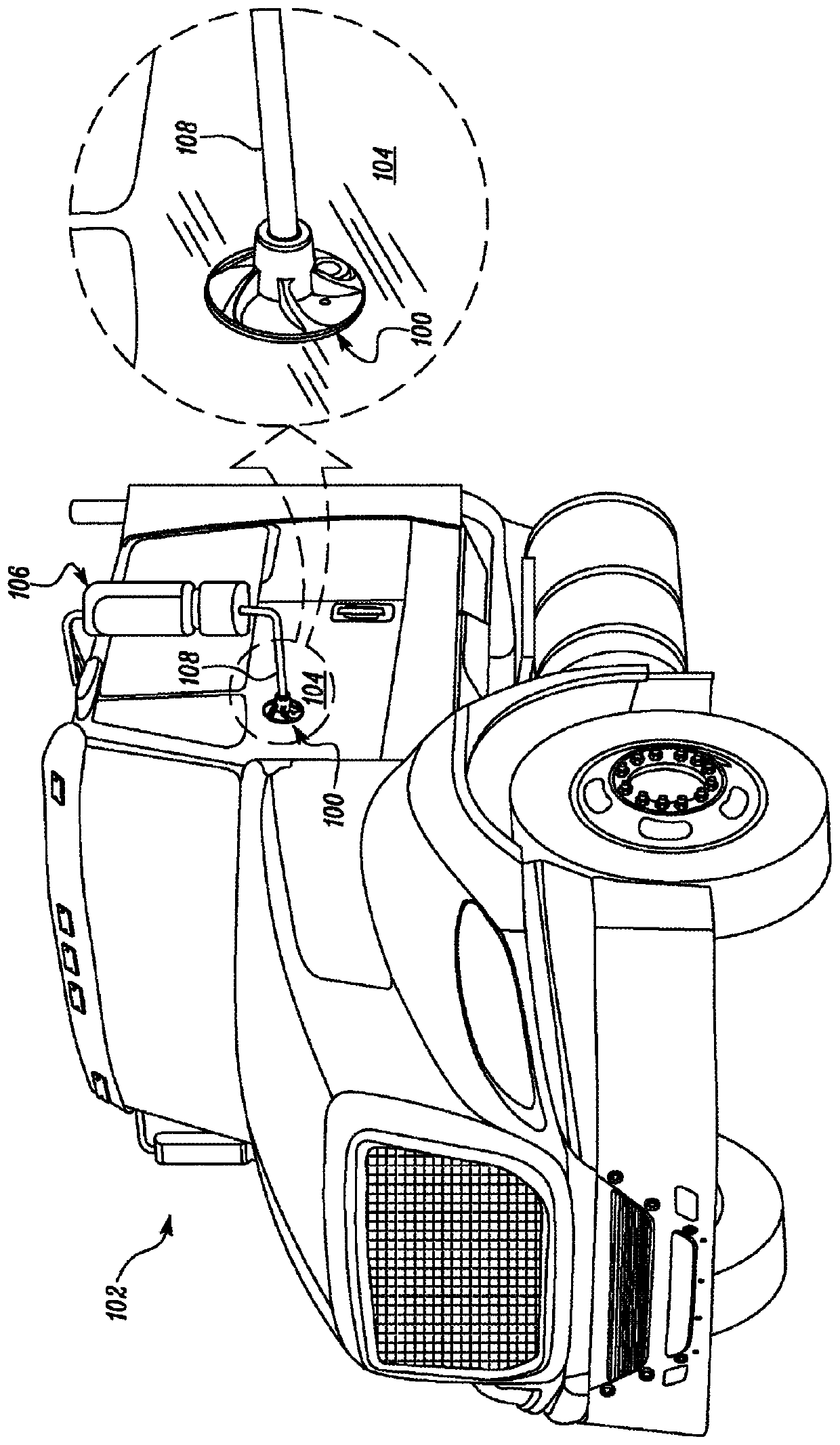

[0023] The present disclosure relates to a mounting structure for adhesively bonding to a surface. figure 1 An exemplary mounting structure 100 is shown attached to a machine 102 in accordance with an embodiment of the present disclosure. Machine 102 is embodied as a truck. However, in various other embodiments, the machine 102 may be any other type of mobile or stationary machine having application in any of earthmoving, mining, construction, railroad, automotive, aerospace, marine, or many other industries . In the illustrated embodiment, the mounting structure 100 is attached to a gate surface 104 (hereinafter surface 104 ) of a machine 102 and supports a component 106 , such as a side mirror. Surface 104 may be any surface and is contemplated including, but not limited to, exterior or interior surfaces associated with machine 102 or any subsystem of machine 102 .

[0024] Component 106 may be supported on mounting structure 100 via attachment hardware 108 associated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com