Rebar formwork integrated wall formwork broken bridge cross-pulling connecting rod

A technology of connecting rods and connecting parts, which is applied to the connecting parts of formwork/formwork/work frame, the on-site preparation of building components, construction, etc. The problem of low applicability of parts is to achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

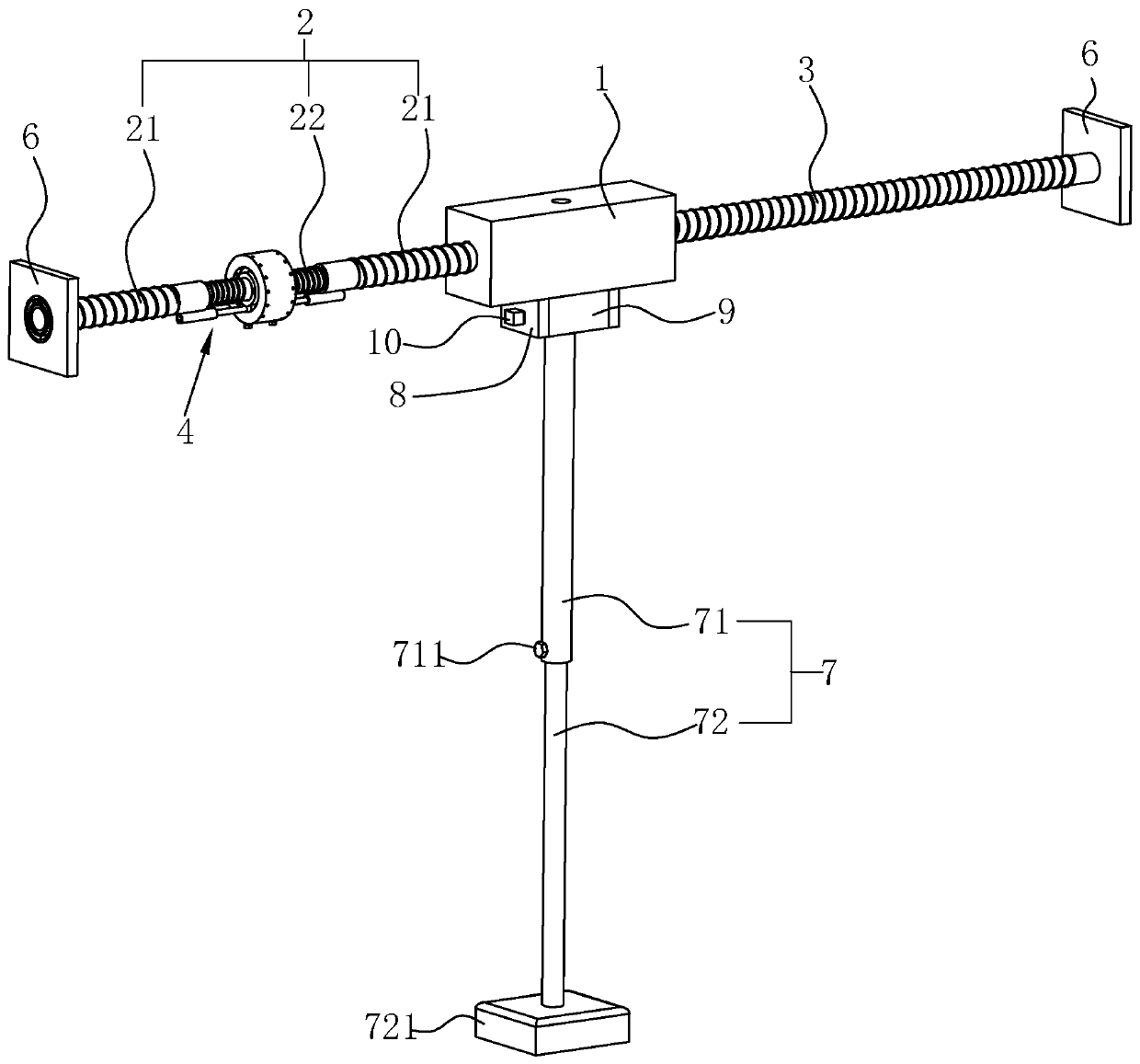

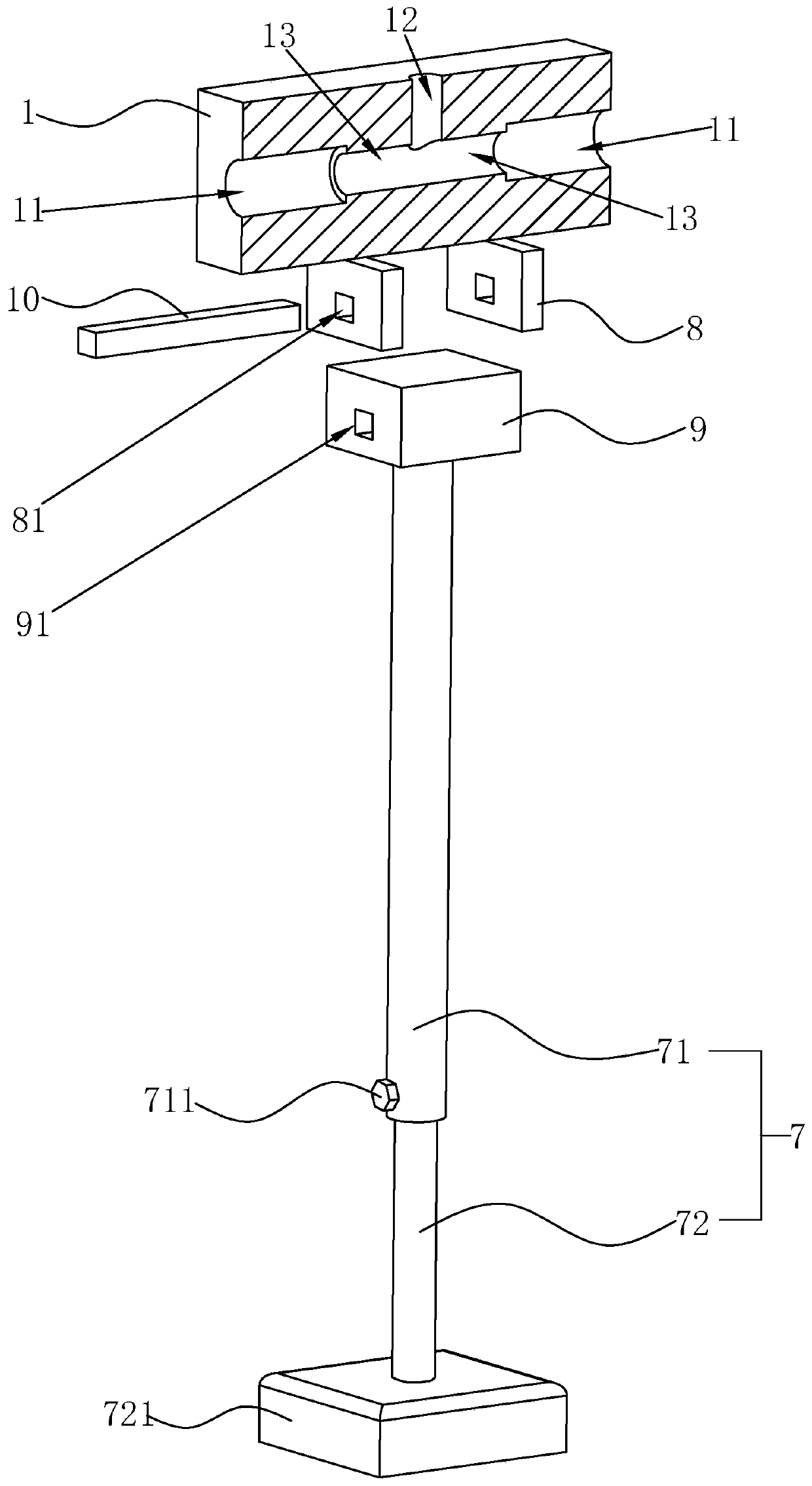

[0036] refer to figure 1 , figure 2 , is a reinforced formwork integrated wall formwork broken bridge pair tension connecting rod member disclosed in the present invention, including a broken bridge connecting piece 1, a first wire rod 2 and a second wire rod 3, and the broken bridge connecting piece 1 Thread grooves 11 are provided on both sides, and the thread grooves 11 can be inserted into the first wire rod 2 and the second wire rod 3; in this embodiment, the shape of the broken bridge connector 1 is a rectangle.

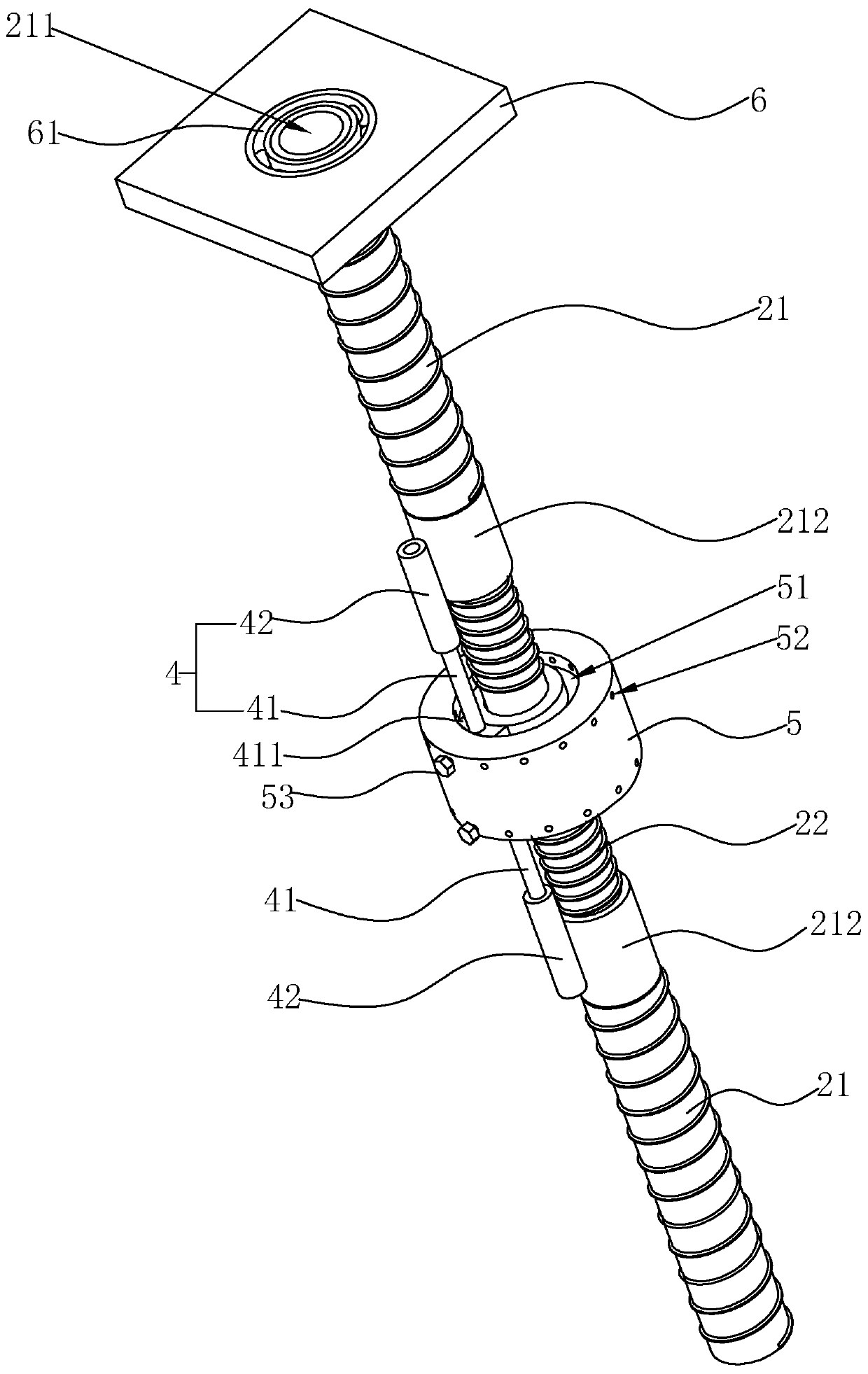

[0037] Such as figure 2 , 3 As shown, the first metal screw rod 2 includes two hollow screw rods 21 and a threaded screw rod 22, the inside of the hollow screw rod 21 is provided with an internal thread matching with the threaded screw rod 22, and the hollow screw rod 21 is connected to the threaded screw rod 22. One is set on each side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com