Mobile position-fixing determination device for electricity meter inspection

A technology for mobile positioning and measuring devices, which is applied in the directions of measuring devices, measuring electrical variables, non-rotating vibration suppression, etc., and can solve problems such as easily damaged electric cards and electric card slot components, staff fatigue, and damage to programming buttons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

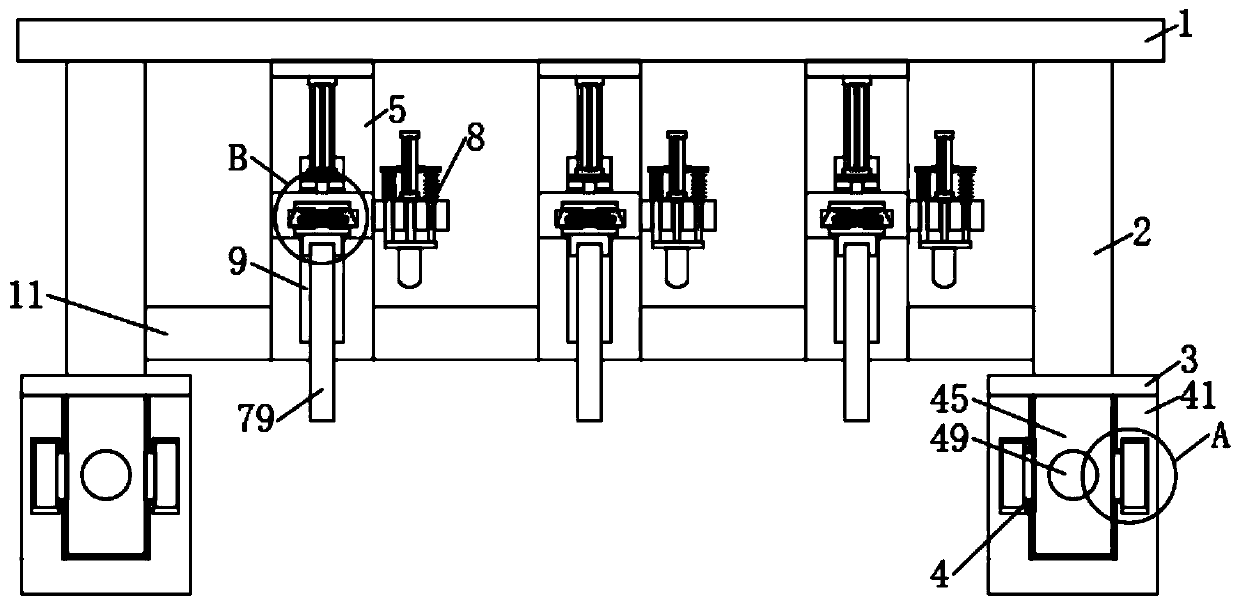

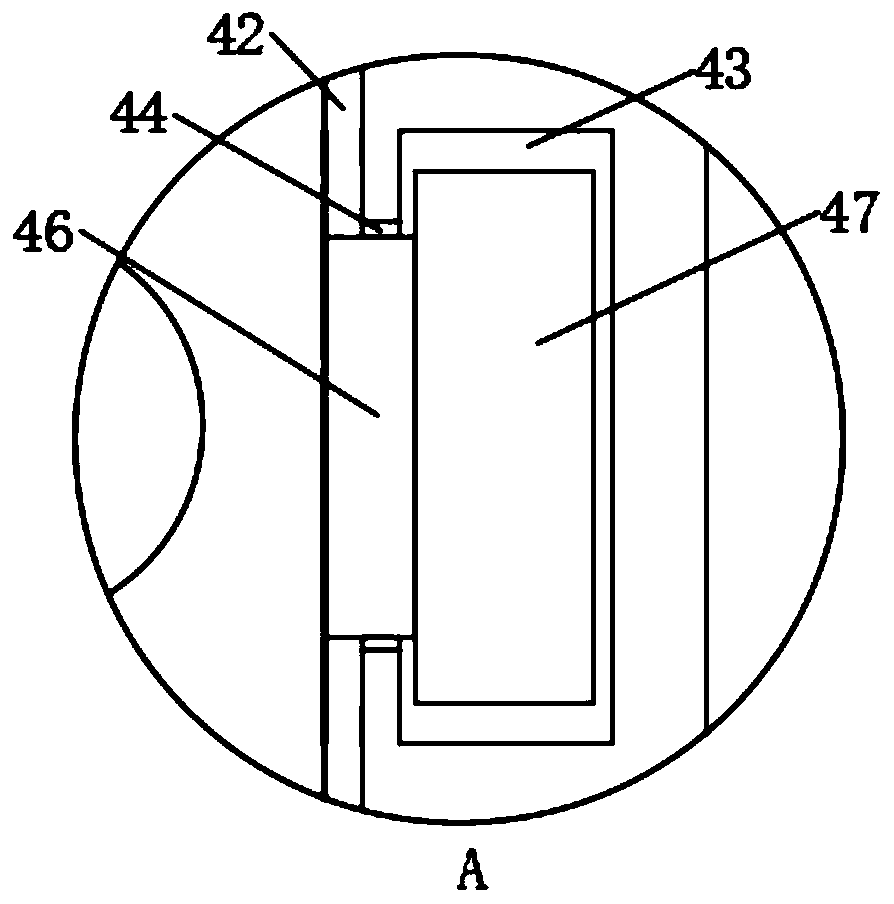

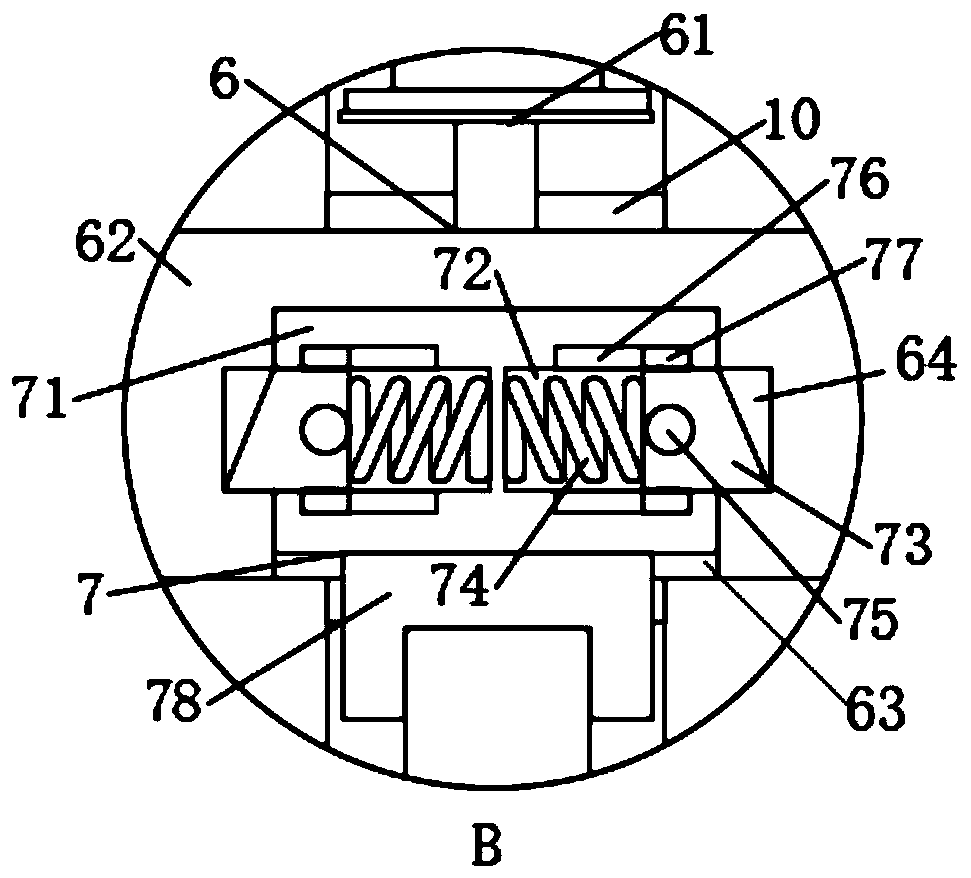

[0026] Example: such as Figure 1-6 As shown, a mobile positioning measuring device for electric energy meter detection in the present invention includes a horizontal plate 1, and both sides of the lower end of the horizontal plate 1 are fixedly connected with support plates 2, and the lower ends of the two support plates 2 are fixedly connected There are seat plates 3, the lower ends of the two seat plates 3 are equipped with sliding seats 4, the lower ends of the horizontal plates 1 are fixedly connected with several mounting plates 5, and some of the mounting plates 5 are in an L-shaped structure, and some of the mounting plates 5 The front of the vertical part of the mounting plate 5 is provided with a third chute 9, the interior of some of the third chute 9 is slidingly connected with a slide plate 10, and the fronts of some of the slide plates 10 are connected with a push-down mechanism 6. The card insertion mechanism 7 and the point pressing mechanism 8 utilize the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com