Laser cutting equipment with liquid spraying device

A technology of laser cutting and liquid spraying device, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of yellowing, hardening, stickiness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

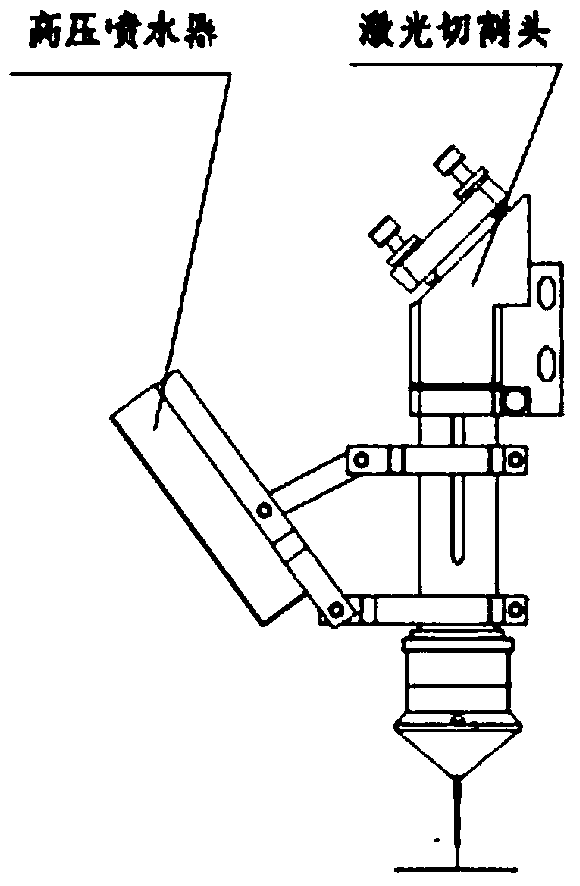

[0011] Please refer to figure 1 , the figure shows a laser cutting device with a liquid spray device provided by the present invention, the device includes:

[0012] Laser cutting head for cutting;

[0013] High-pressure sprinklers for spraying water;

[0014] The solenoid valve is used to control the laser cutting head and the high-pressure water jet, so that the laser cutting head cuts and the high-pressure water jet sprays water at the same time.

[0015] Among them, the slit produced by the laser cutting head coincides with the focus of the high-pressure water jet.

[0016] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com