Integrated magnetohydrodynamic drive

A thruster and magnetic fluid technology, applied in ship propulsion, propulsion components, ship components, etc., can solve problems such as difficult to ship or independent use, bulky, heavy magnetic fluid propulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

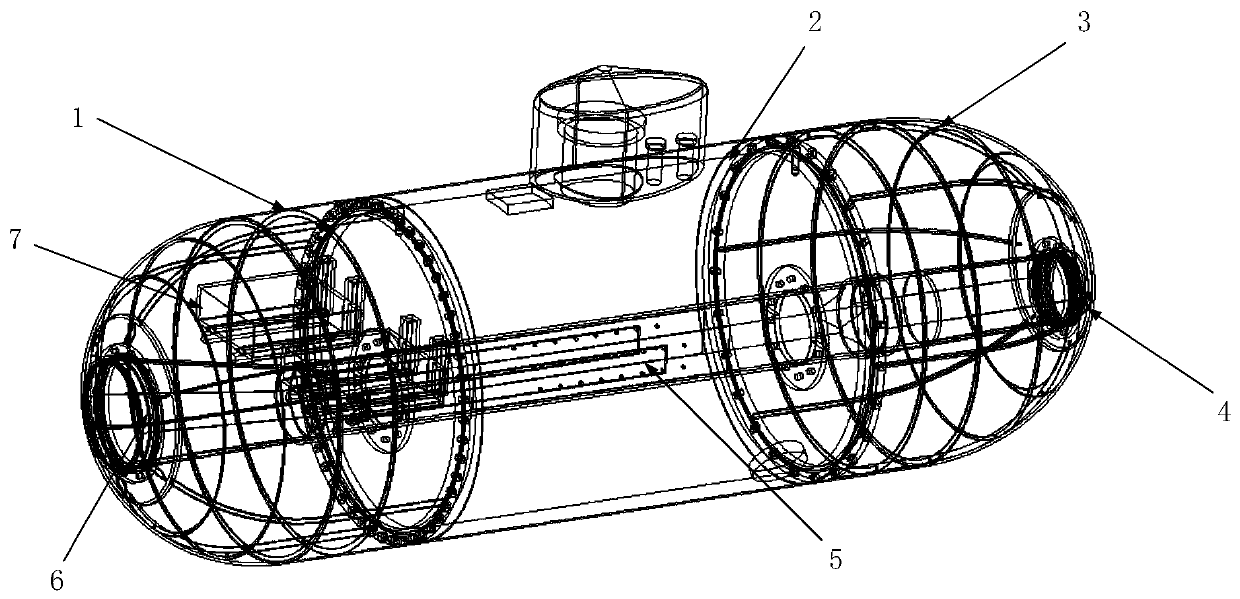

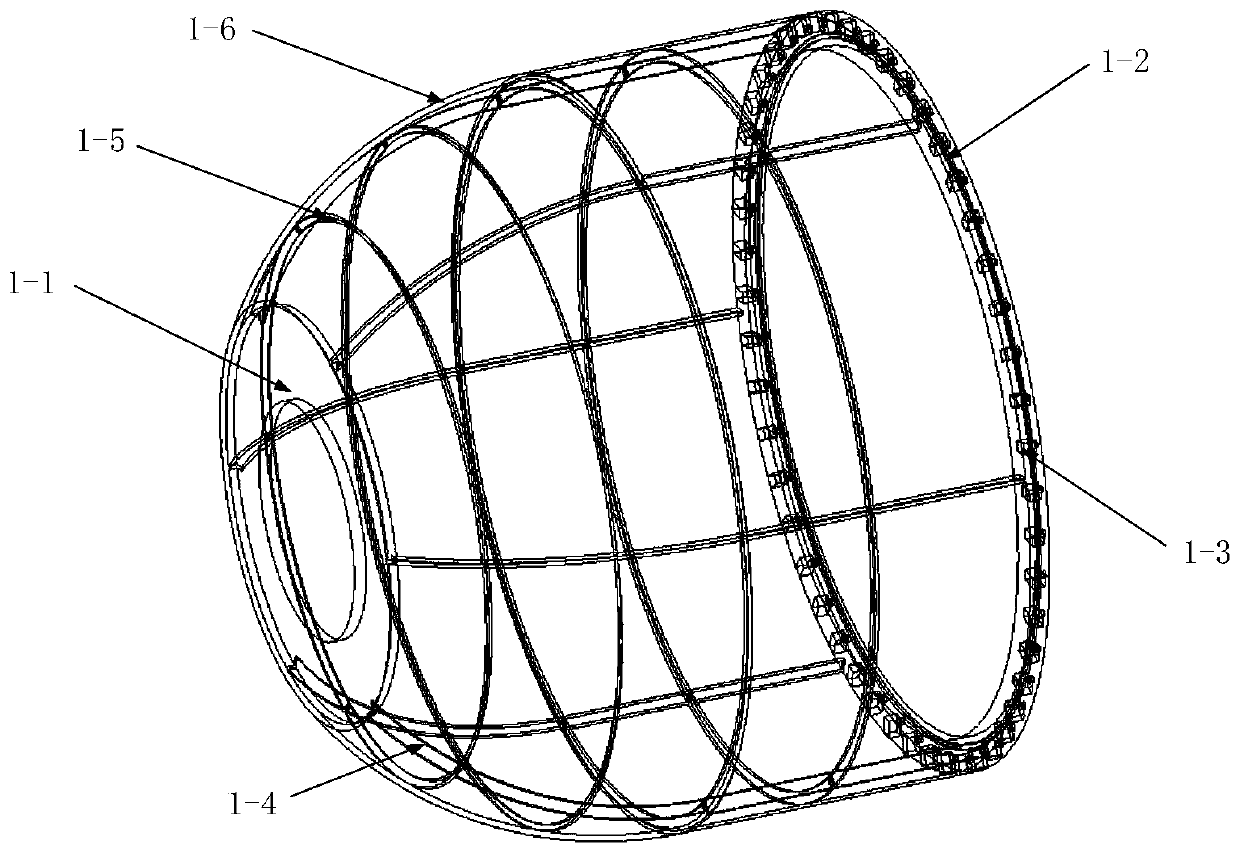

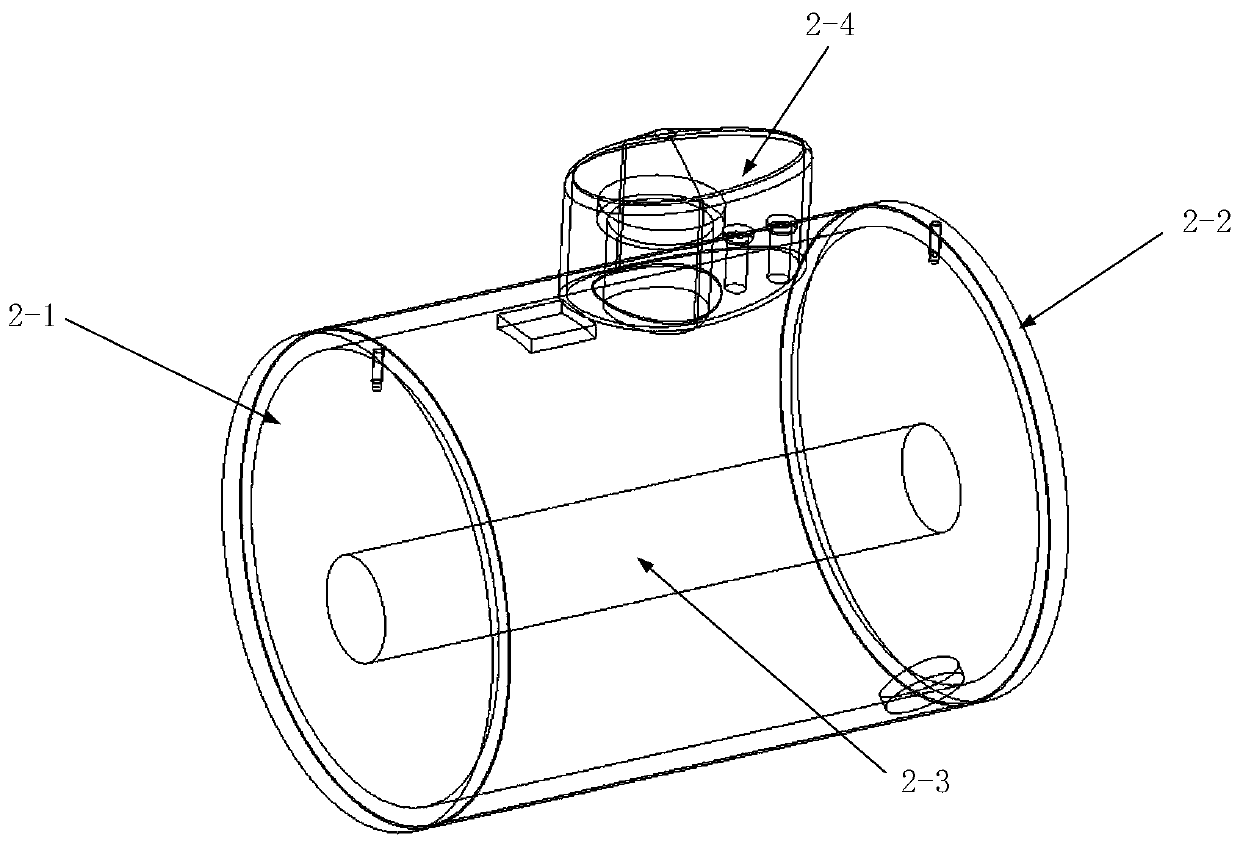

[0028] Such as figure 1 As shown, the integrated magnetic fluid propeller of the present invention is a streamlined structure, the left side is the inlet end, which is a hemispherical structure; the middle part is the propeller part, which is a cylindrical shell structure; the right side is the nozzle end, which is A semi-ellipsoidal structure. The integrated magnetic fluid thruster of the present invention is, from left to right, an inlet cavity, an MHD thruster cavity, and an exit cavity. The superconducting magnet 2 and the propulsion channel 5 form the cavity of the MHD thruster, the inlet casing 1, the inlet connecting section 6, and the left load-bearing flange (2-1) of the superconducting magnet 2 are connected in sequence to form the inlet cavity, and the outlet casing 3. The outlet connecting section 4. The right load-bearing flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com