Miniaturized high-pressure piezoelectric proportional valve based on spring tube displacement amplification

A displacement amplification and spring tube technology, applied in the mechanical field, can solve the problems of low sealing reliability and complex structure, and achieve the effects of high reliability, long life and strong pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

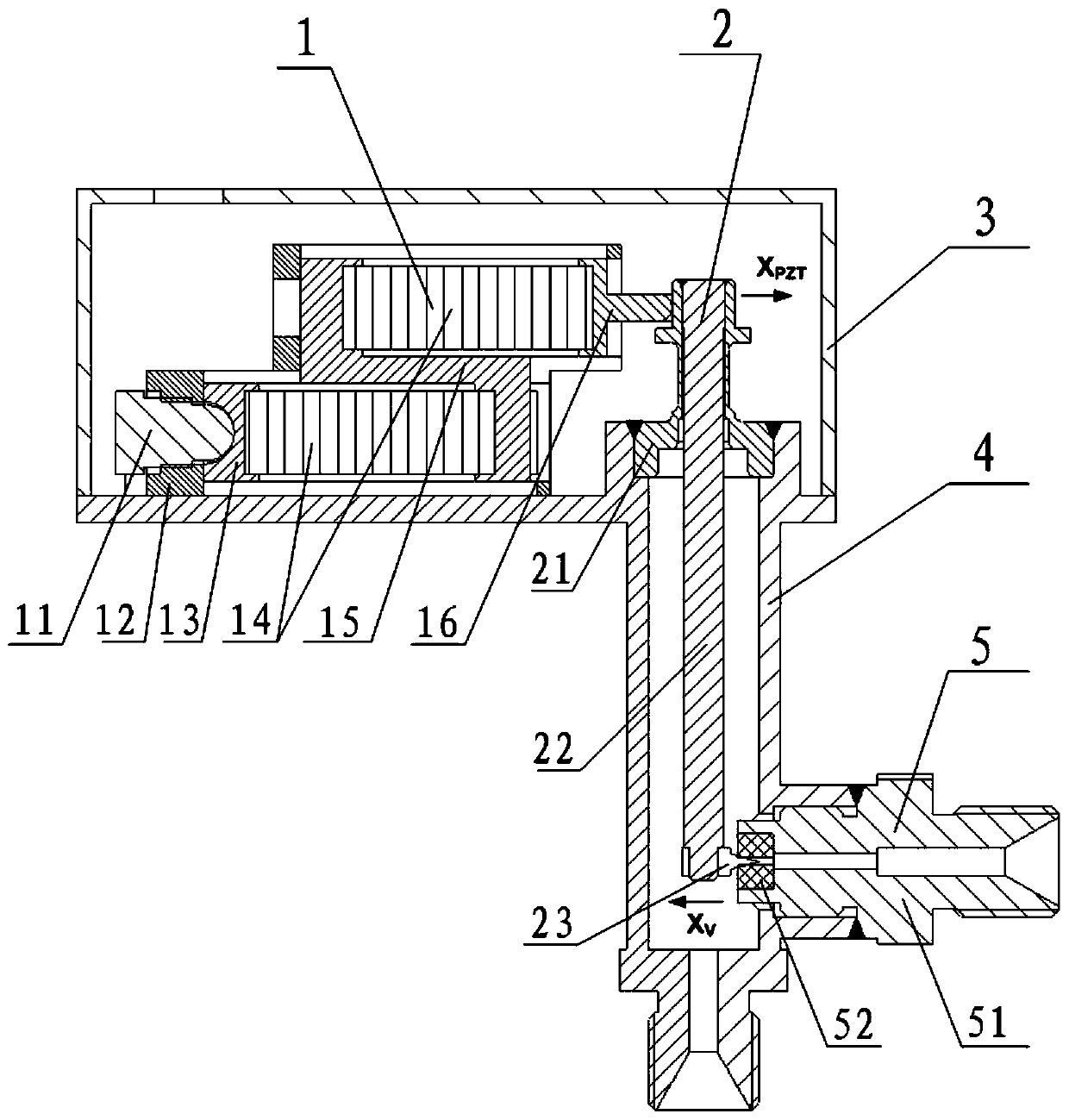

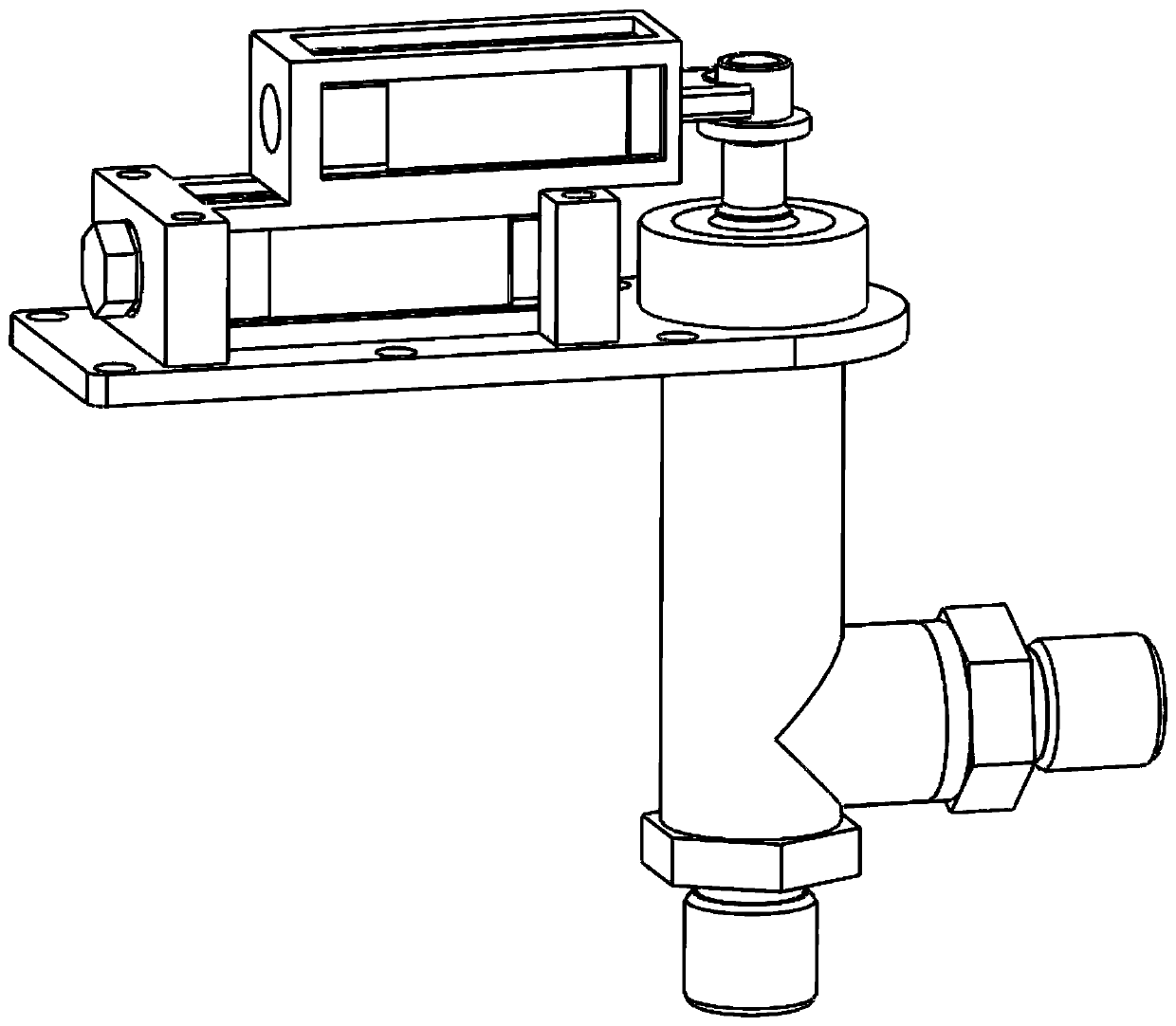

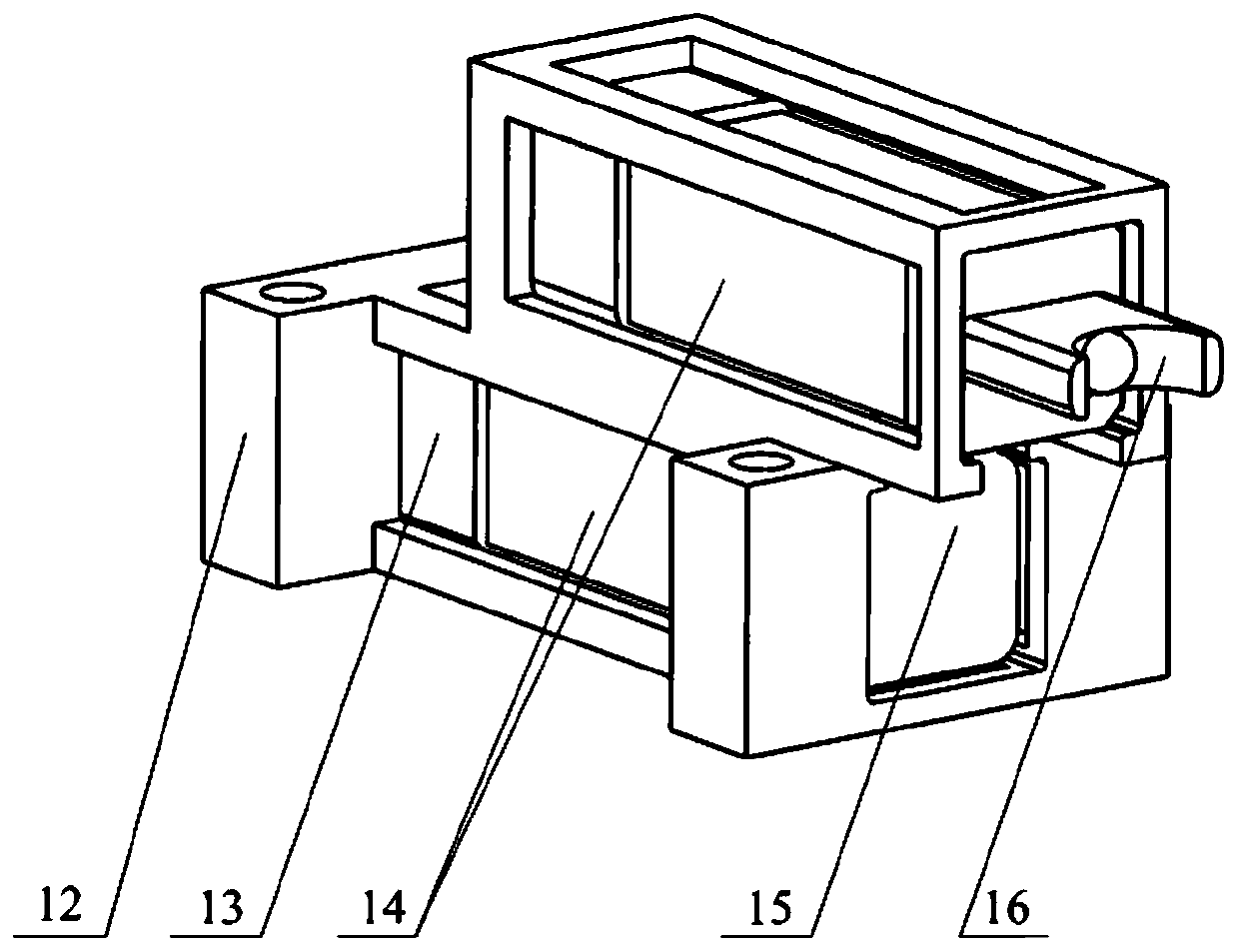

[0033] Such as figure 1 As shown, it is a two-dimensional sectional view of a high-voltage piezoelectric proportional valve of the present invention, wherein the piezoelectric drive assembly 1 is a device that generates displacement through piezoelectric ceramics, and is the driving force of the piezoelectric proportional valve product; the elastic amplification assembly 2 functions to The displacement of the piezoelectric drive component 1 is amplified to the opening of the valve port, and at the same time realizes high-pressure dynamic sealing; the outer cover 3 is a hollow thin-walled cuboid structure, and its function is to provide dustproof protection for the piezoelectric drive component 1; the main structure of the valve body 4 It is a hollow tube structure, which provides the installation interface for the piezoelectric drive component 1, the elastic amplification component 2, the outer cover 3 and the air outlet joint 5, and provides the connection interface for the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com