Automobile four-door two-cover endurance test bench

A four-door, two-cover, durability test technology, which is applied in vehicle testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as low test platform construction efficiency, heavy workload, and profile damage, and achieve The strength and fatigue resistance of the bench are strong, the construction efficiency is accelerated, and the adjustment is convenient and efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

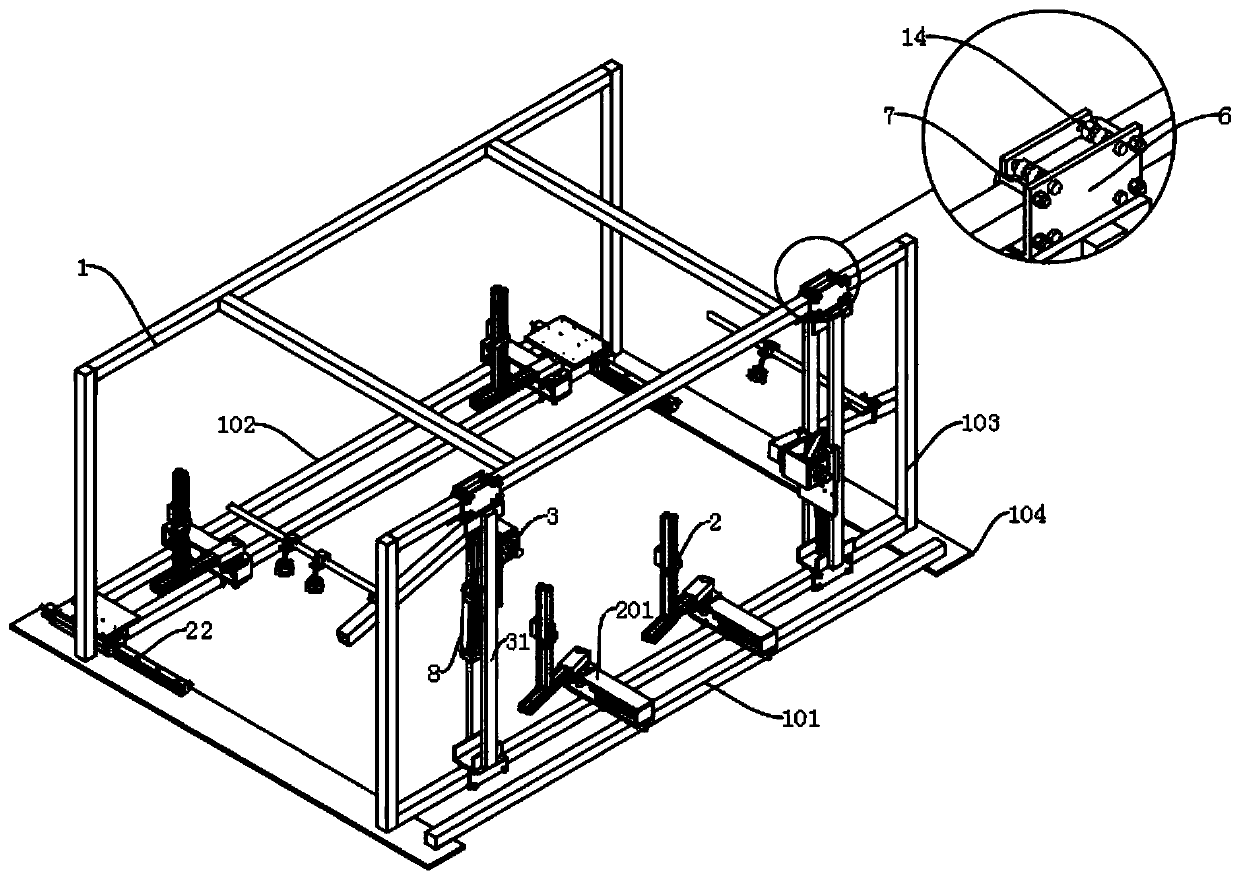

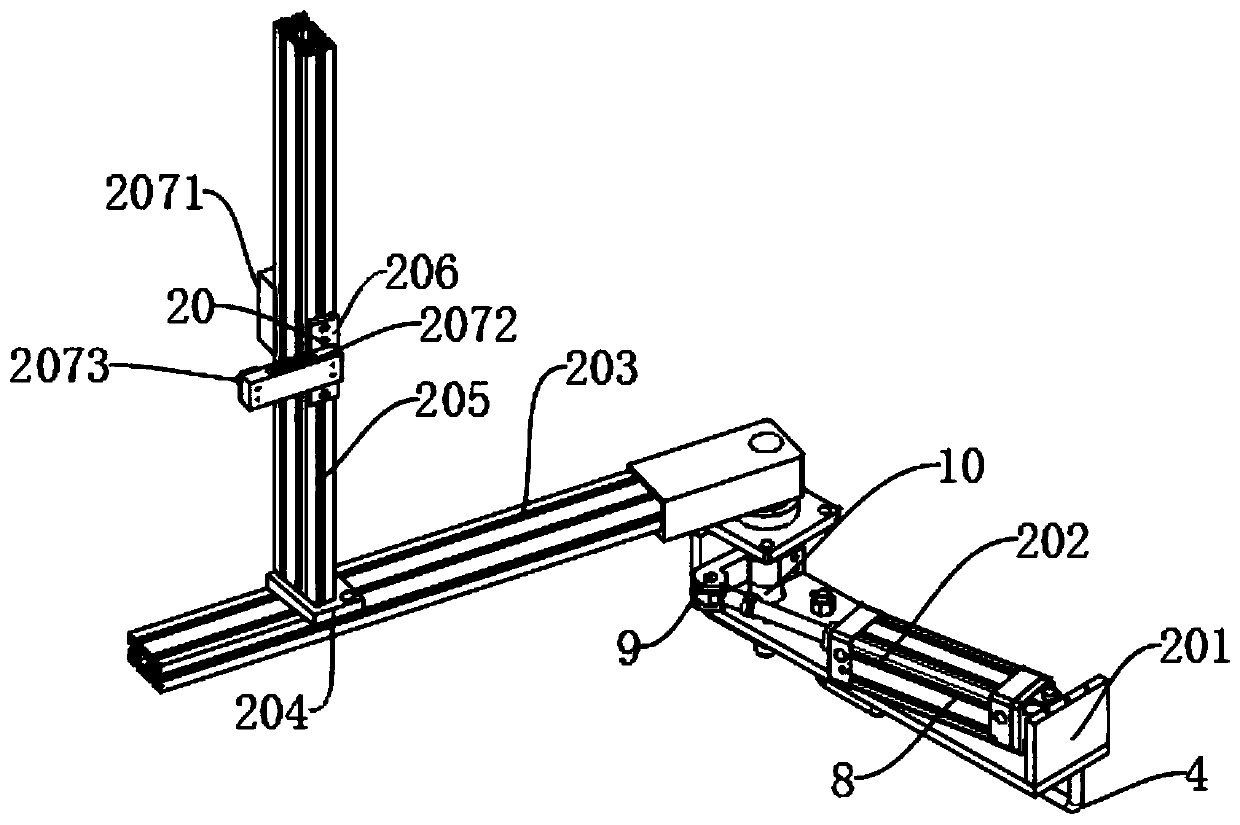

[0037] The present invention provides such Figure 1-6 The four-door and two-cover endurance test bench for automobiles shown includes a main body frame 1, and a door opening and closing mechanism 2 and a car cover opening and closing mechanism that can be adjusted in translation along the frame are provided on the frames on both sides of the main body frame 1. Agency 3;

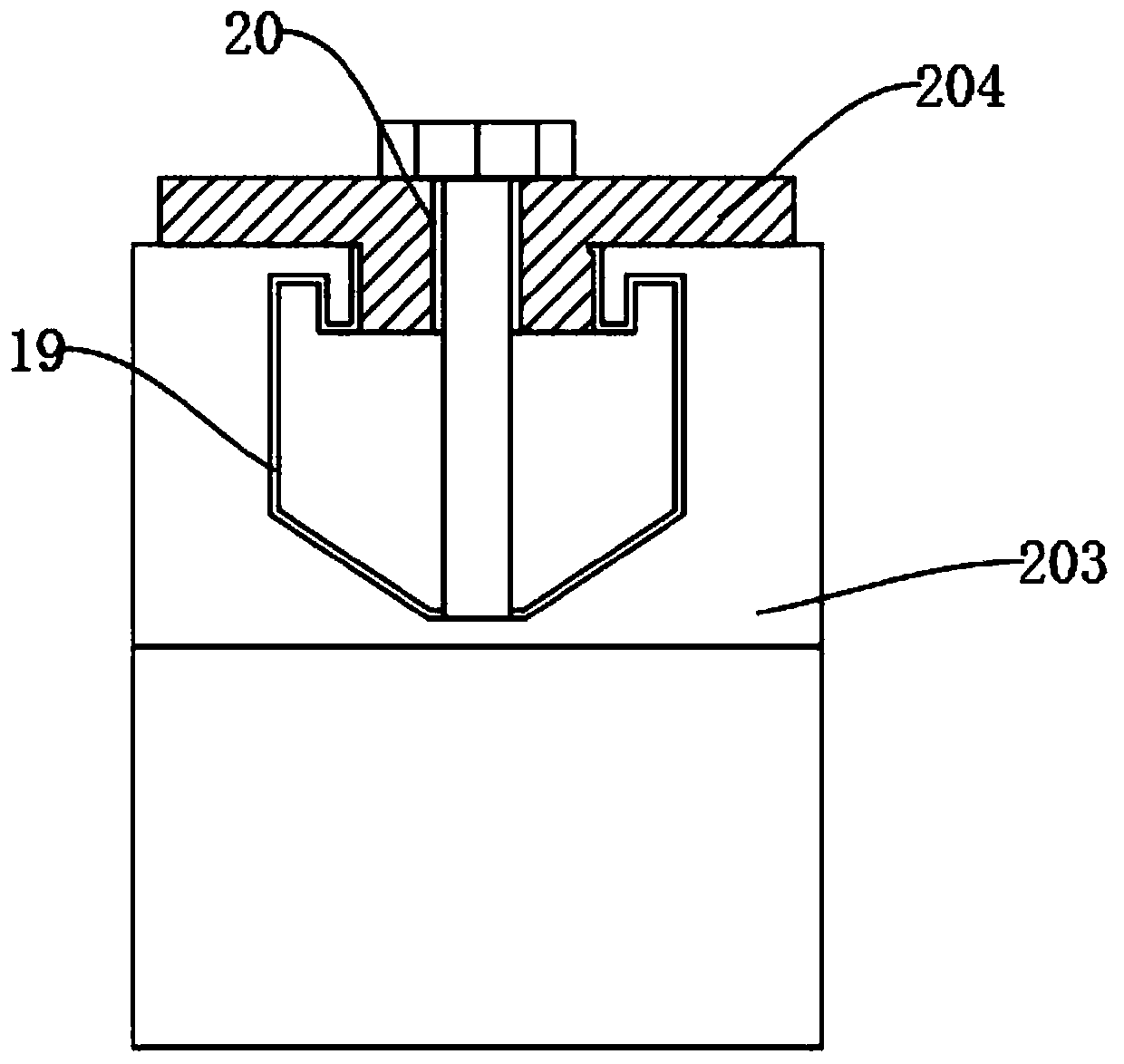

[0038] The rectangular frame 201 of the door opening and closing mechanism 2 is arranged on two side-by-side poles at the lower end of the main frame 1, and the lower side of the rectangular frame 201 is fixed with a U-shaped bolt A4 through a nut, and when the nut is tightened, The U-shaped bolt A4 hooks the two poles and the bottom side of the rectangular frame 201 and presses them. When the nut of the U-shaped bolt A4 is unscrewed, the door opening and closing mechanism 2 is pulled along the two poles arranged side by side at the lower end of the main frame 1. Move and adjust the position; adjust the pos...

Embodiment 2

[0051] Such as Figure 7 as shown,

[0052] The difference from Embodiment 1 is that both the first drive deflection mechanism 202 and the second drive deflection mechanism 32 are composed of a servo motor 11 and a reducer 12, and the output shaft of the servo motor 11 is connected to the output shaft of the reducer 12 The shaft is fixedly connected. The drive is used to replace the pneumatic, and the electric has the advantages of simplified structure, accurate parking, random acceleration and deceleration, strong controllability, and low noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com