Sampling type fission ionization chamber and fission total number measuring method based on same

An ionization chamber and electrical connection technology, which is applied in the field of fission ionization chamber, can solve the problem of great impact on the health of measurement personnel, poor measurement uncertainty of ionization chamber neutron energy spectrum consistency, inability to measure gas fission products and short-lived fission products and other problems, to achieve the effect of reducing the radioactive dose and reducing the radioactive dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

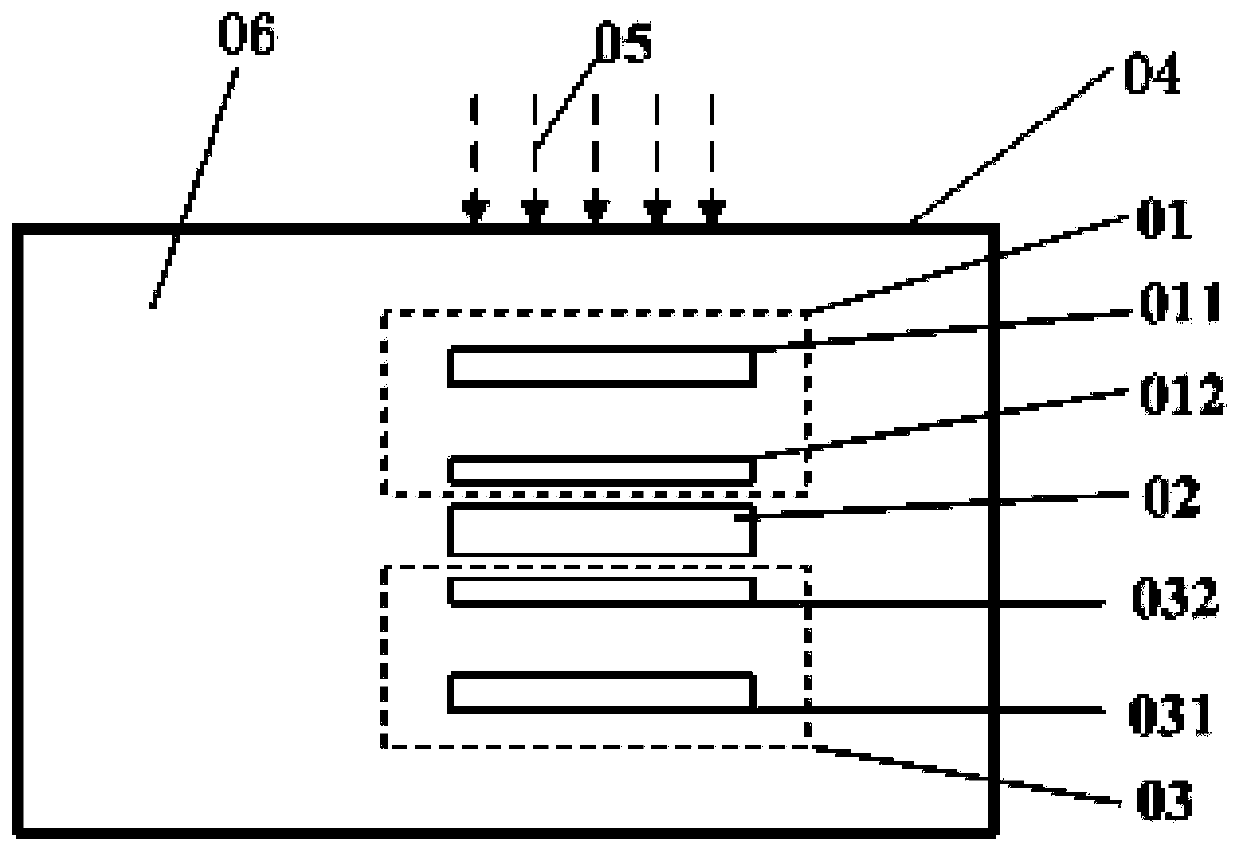

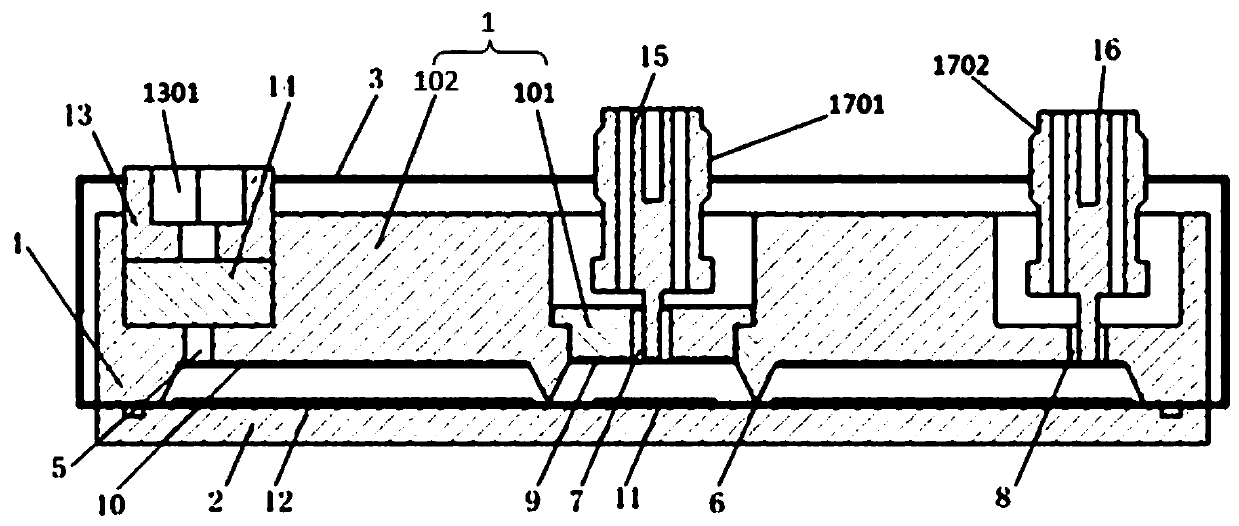

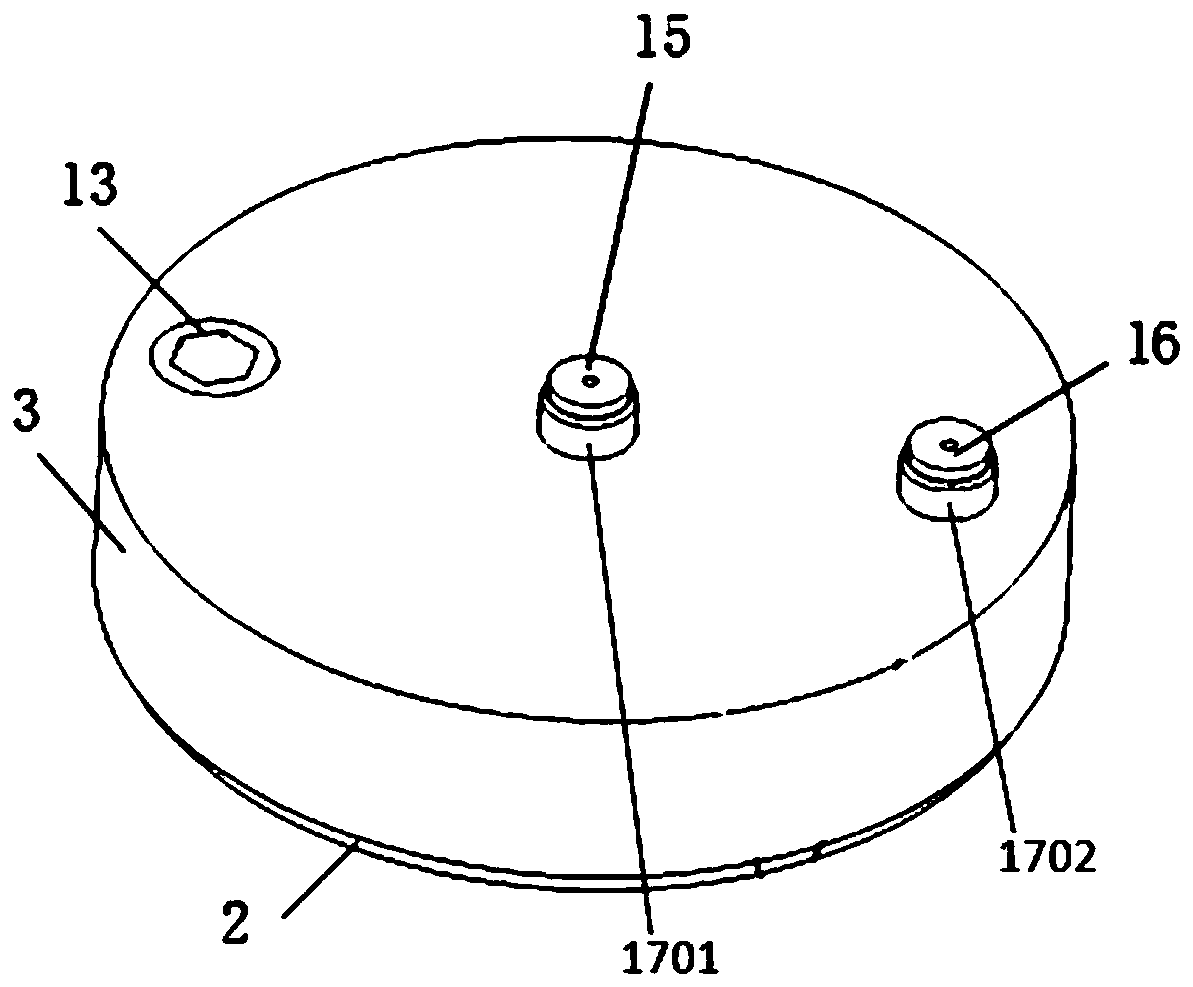

[0062] see figure 2 and image 3 , a pumping-type fission ionization chamber of the present invention, comprising a cathode support 2 and a cathode 3 arranged coaxially and fixedly connected sequentially from bottom to top, an anode support 1 arranged in the cavity of the cathode 3 and coaxial with the cathode 3, and further comprising The sampling anode 9, the ring anode 10, the sampling cathode sleeve 1701, the balance cathode sleeve 1702, the sampling anode column 15, the balance anode column 16 and the working gas introduction unit. The above-mentioned cathode 3 is detachably connected by an upper part and a lower part, enclosing a chamber. In this embodiment, the cathode support 2 is preferably cylindrical; the upper part of the cathode 3 is a cylindrical upper cover, and the lower part is a circular bottom plate, and the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com