Connector

A connector and external technology, applied in the direction of connection, connecting device parts, contact parts, etc., can solve the problems of poor connector tolerance, unreliable connection, etc., to improve the structure, reduce interference, and improve heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

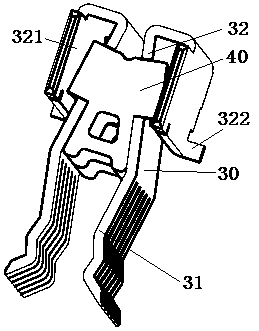

[0070] Embodiment 3 of the connector in the present invention: the difference from the above-mentioned embodiments is that in this embodiment, the force-limiting clamp is a U-shaped structure, and the bottom edge of the force-limiting clamp and the insulator face the force-limiting transmission. Between the sides of the force clamps, there is reserved space for the limit force transmission clamp to swing relative to the insulator. When the adapter insert is inserted into the socket with a certain lateral deviation, the adapter contact is applied to the two conductors. A lateral force in the sheet and pushes it to shift laterally, the limit force transmission clip can also swing by itself while transmitting the force to the other conductive sheet, and is not limited to the use of the limit force transmission clip One of the bottom edge of the insulator and the side of the insulator facing the position-limiting force-transmitting clip is provided with a convex portion, and the ot...

Embodiment 5

[0072] Embodiment 5 of the connector in the present invention: the difference from the above embodiments is that in this embodiment, the part of the conductive sheet that constitutes the insertion jaw can be a complete plate body, and the clip of the limit force transmission clip The arm directly abuts against the board surface of the board body, and is not limited to the solution of setting a comb-like structure on the conductive sheet. Or the part of the conductive sheet that constitutes the plug-in jaw is still designed as a comb-shaped structure, and the part that cooperates with the comb-shaped structure in the clamp arm of the limit force transmission clamp is no longer provided with limit ribs, but relies on the complete end surface and the comb structure. Comb structure against the top fit.

Embodiment 6

[0073] Embodiment 6 of the connector in the present invention: the difference from the above embodiments is that in this embodiment, the structure used to communicate with other contacts in the conductive sheet can be arranged at the tail end of the conductive sheet in the insertion direction , not limited to the scheme of setting the sheet-shaped outer connection section at the top position of the conductive sheet perpendicular to the insertion direction, and at this time, there is no need to make an avoidance structure for avoiding the sheet-shaped outer connection section on the housing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com