Automatic screw locking machine

A technology of automatic screw locking machine and screw locking mechanism, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

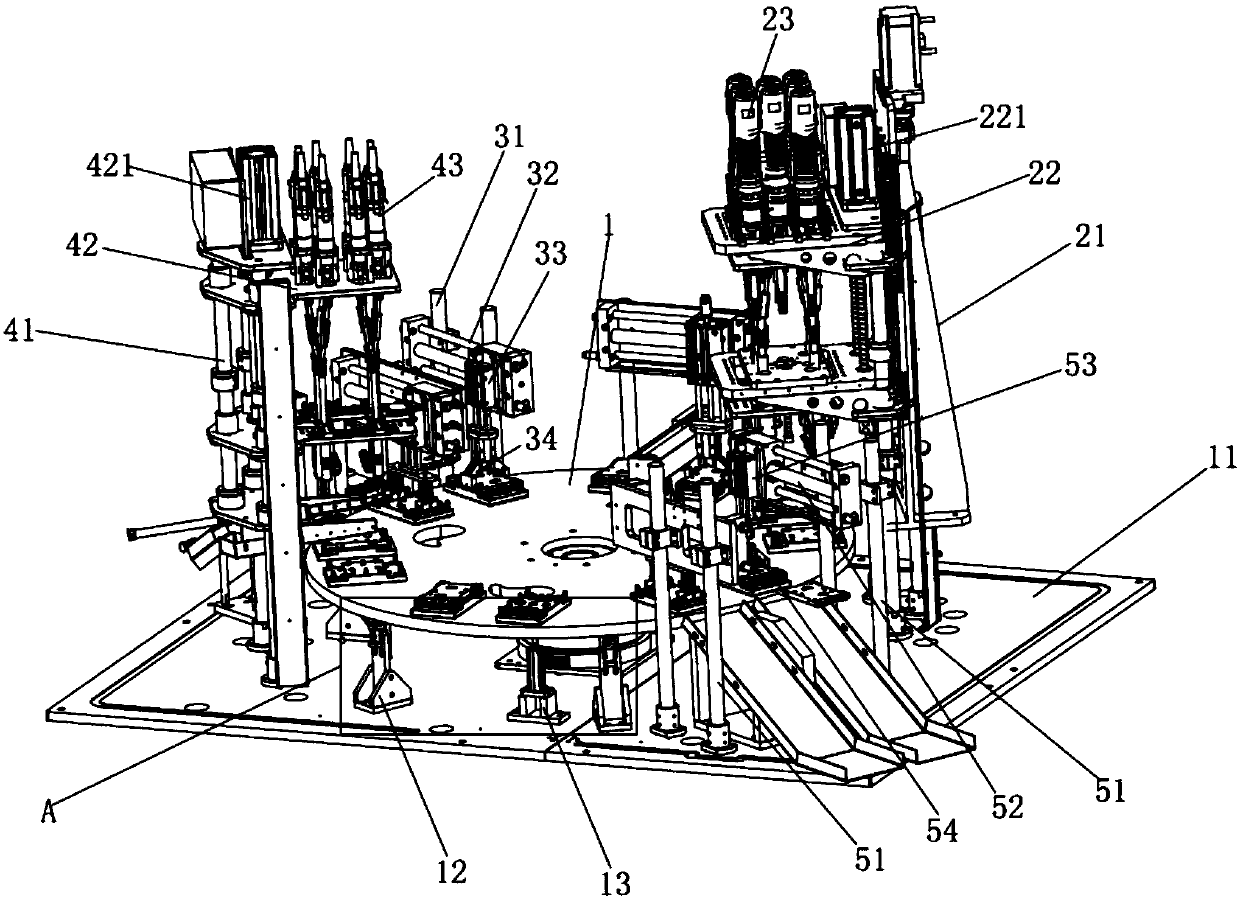

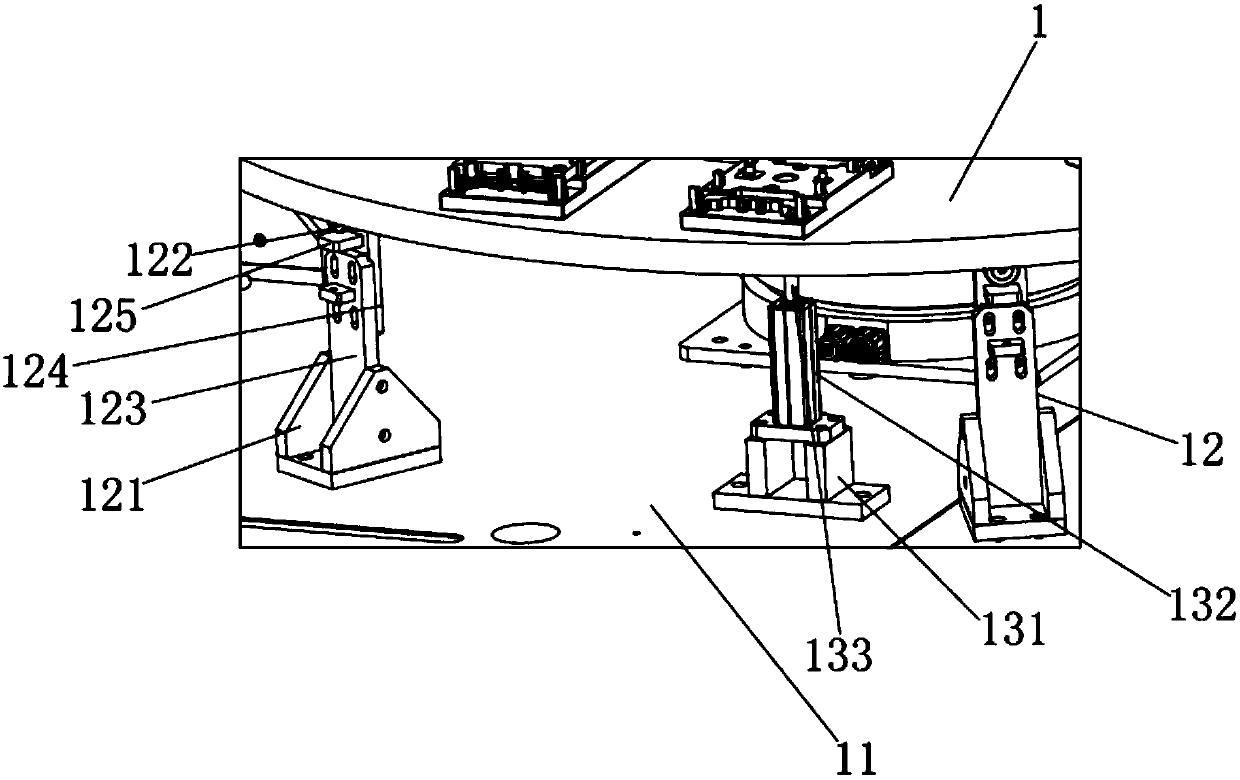

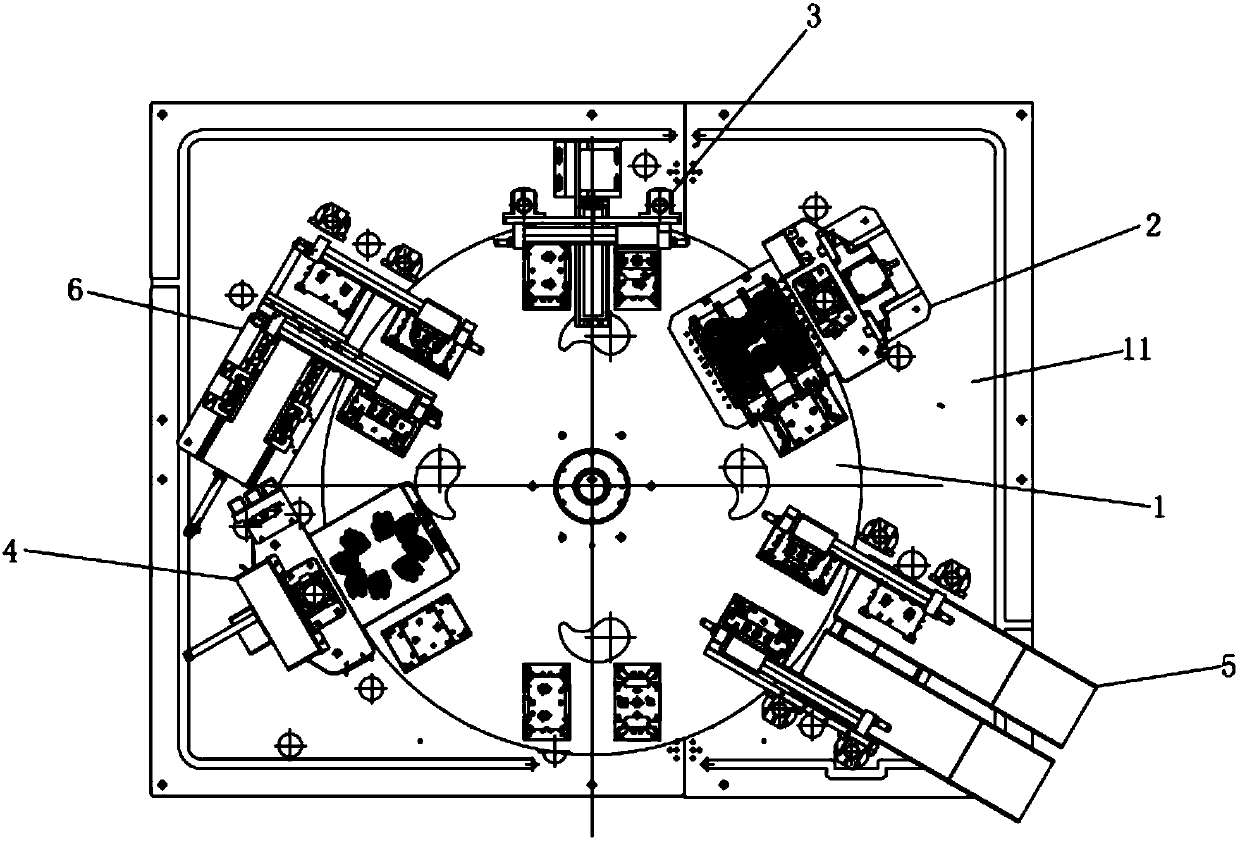

[0023] see Figure 1 to Figure 4 , the figure shows an automatic locking screw machine provided by Embodiment 1 of the present invention, which includes a turntable 1, which is rotatably mounted on a base 11, and a first lock surrounding the turntable 1 is fixedly installed on the base 11 Screw mechanism 2, first loading and unloading mechanism 3, second locking screw mechanism 4 and second loading and unloading mechanism 5, first locking screw mechanism 2, first loading and unloading mechanism 3, second locking screw mechanism 4 and second loading and unloading mechanism Mechanisms 5 are sequentially arranged clockwise or counterclockwise along the turntable 1, and a plurality of first guide mechanisms 12 are fixedly installed between the base 11 and the turntable 1, and the plurality of first guide mechanisms 12 are arranged along the circumferential direction of the turntable 1. Arranged equidistantly, the first guide mechanism 12 includes a first base 121 fixedly installed...

Embodiment 2

[0026] see Figure 1 to Figure 4 , the figure shows an automatic screw locking machine provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first guide roller 122 Move back and forth on the first base 121 in the vertical direction; Specifically, the first mounting plate 123 arranged along the vertical direction is fixedly installed on the first base 121, and the second mounting plate 123 is slidably connected to the first mounting plate 123. 124 , the top of the second mounting plate 124 is rotatably connected with the first guide roller 122 . Through the setting of the above structure, the self-adaptive adjustment of the height of the first guide roller with respect to the turntable can be realized.

Embodiment 3

[0028] see Figure 1 to Figure 4 , the figure shows an automatic locking screw machine provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the second mounting plate 124 A guide plate 125 arranged horizontally is fixedly connected to the top, and the surface of the first guide roller 122 contacts the surface of the guide plate 125 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com