Device facilitating wheel replacement

A wheel and sliding installation technology, which is applied in the direction of wheel assembly and disassembly equipment, wheel, tire installation, etc., can solve problems such as inconvenient, affecting work efficiency, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

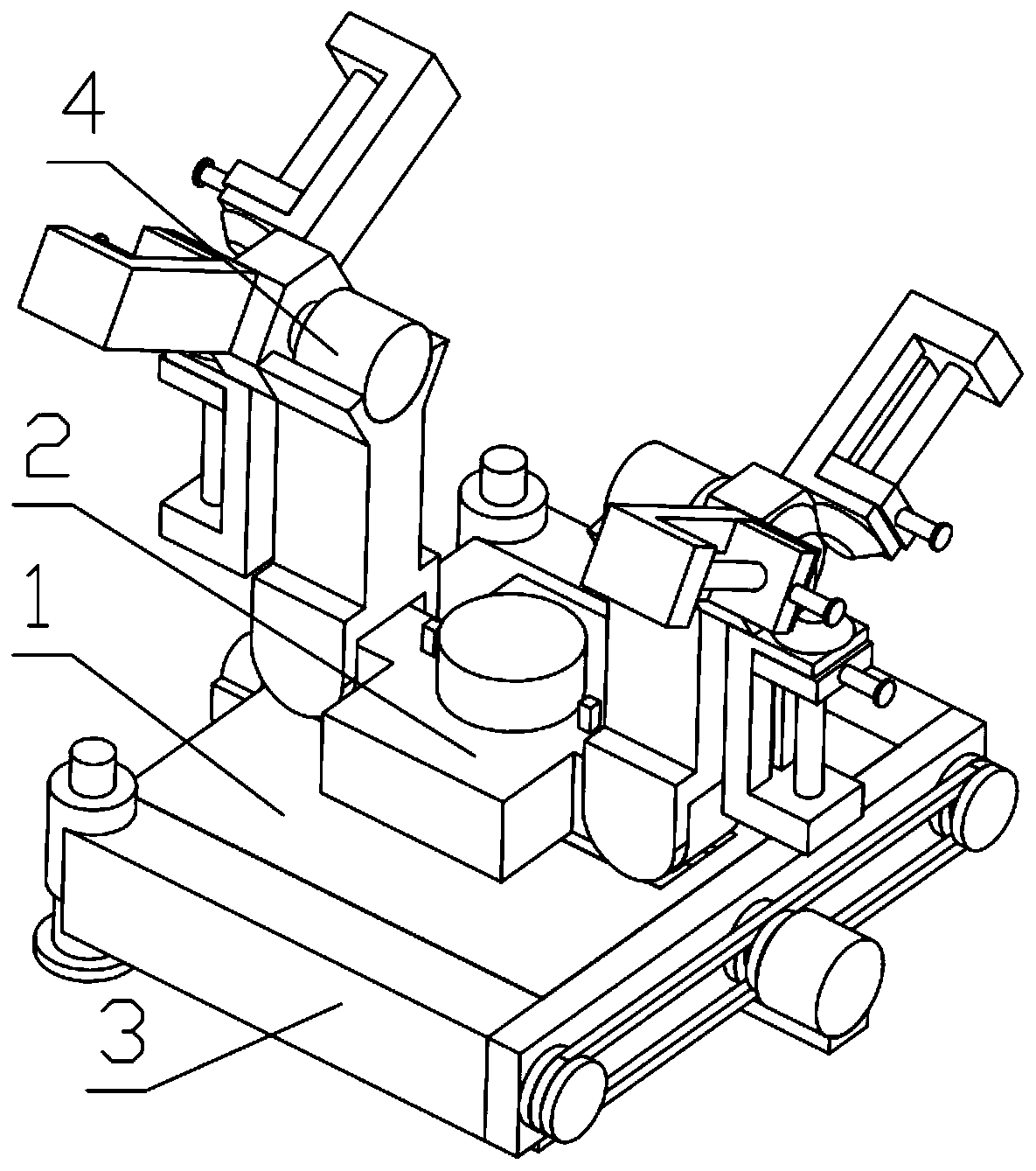

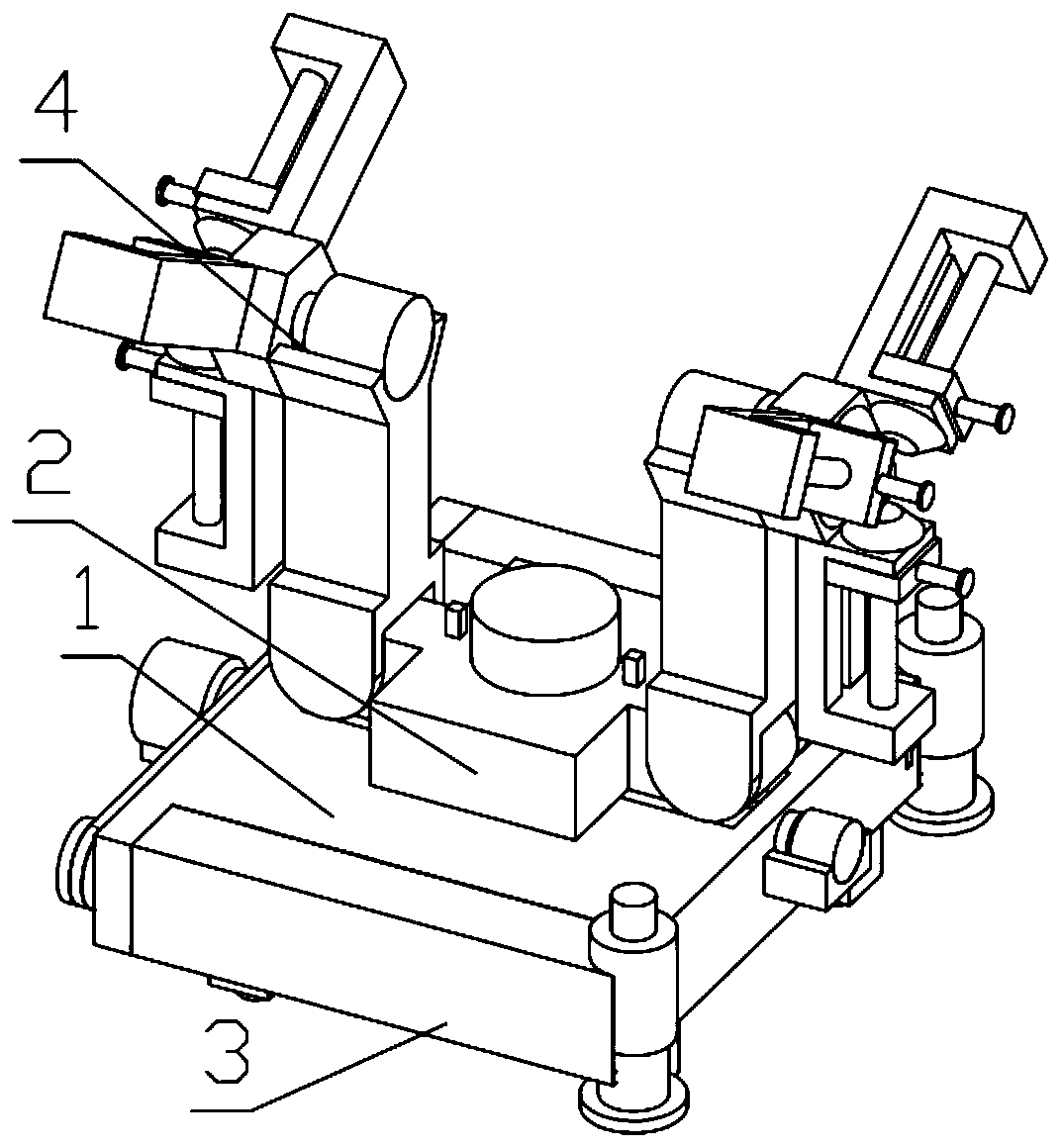

[0035] Combine below Figure 1-13 Description of this embodiment, a device for easy wheel replacement, including a device base 1, the rotating mechanism 2 is installed on the device base 1, the jack mechanism 3 is installed on the device base 1, and the wheel clamping mechanism 4 is installed on the rotating mechanism 2 on.

specific Embodiment approach 2

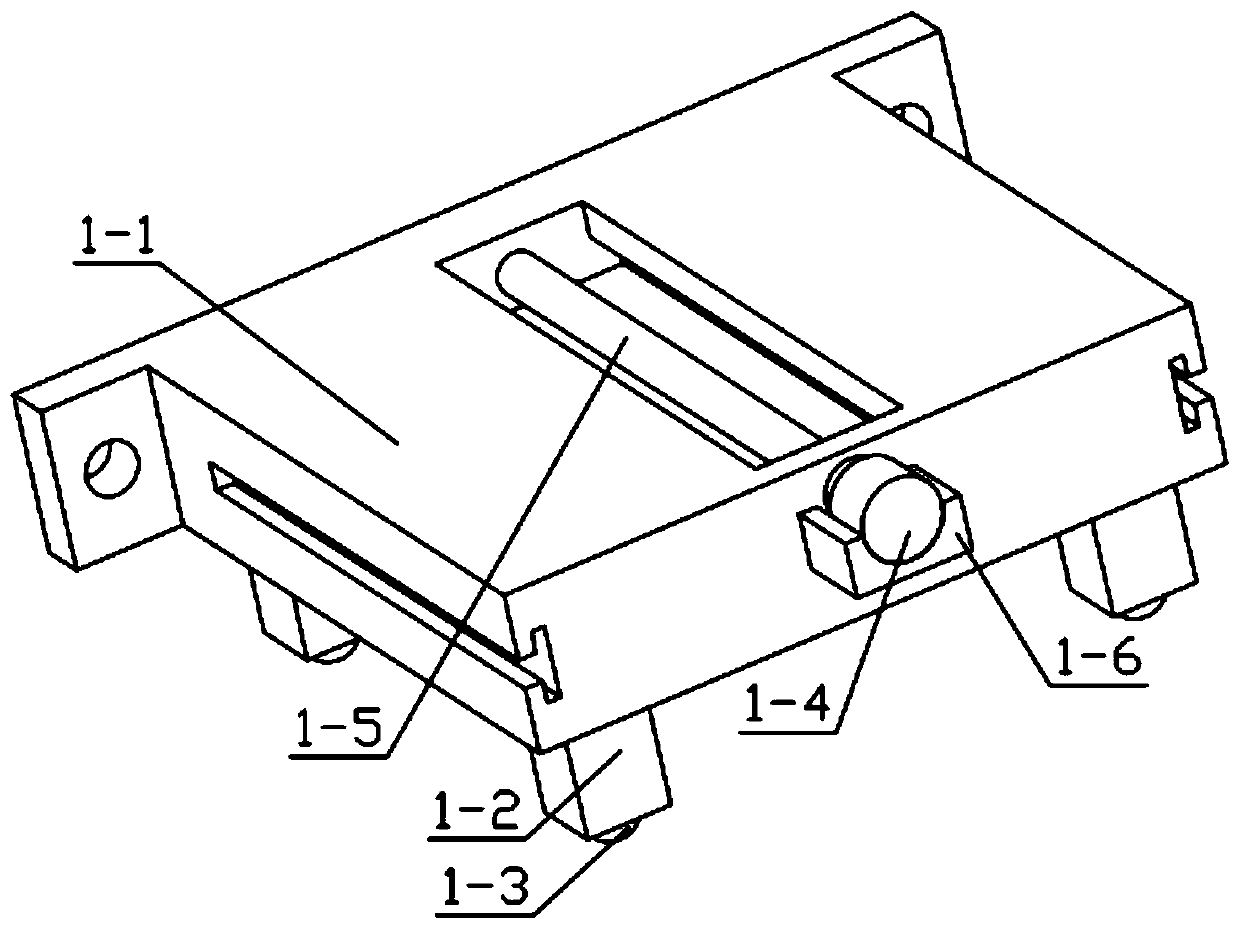

[0037] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the first embodiment, the device base 1 includes a base body 1-1, support legs 1-2, universal wheels 1-3, small motor 1-4, threaded rod 1 -5. The motor base 1-6, the motor base 1-6 is fixedly installed on the base body 1-1, the small motor 1-4 is fixedly installed on the motor base 1-6, and the supporting legs 1-2 are fixedly installed on the base body 1 -1, the universal wheel 1-3 is installed on the support leg 1-2, the threaded rod 1-5 is rotatably installed on the groove provided on the base body 1-1, and the threaded rod 1-5 is fixedly installed on the small motor 1 -4 output.

specific Embodiment approach 3

[0039] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the second embodiment, the rotating mechanism 2 includes a special-shaped connection shell 2-1, a U-shaped insert 2-2, a resistance rubber ring 2-3, a T-shaped screw 2- 4. Cylindrical piece 2-5, mobile rolling ball 2-6, motor for rotation 2-7, motor output turntable 2-8, internal spring 2-9, one end of internal spring 2-9 is fixedly installed in special-shaped connection shell 2 In the groove provided on -1, the other end of the internal spring 2-9 is fixedly installed on the U-shaped plug-in 2-2, and the U-shaped plug-in 2-2 is slidably installed on the groove provided on the special-shaped connection shell 2-1, The cylindrical part 2-5 is fixedly installed on the T-shaped threaded part 2-4, the mobile rolling ball 2-6 is movably installed in the groove provided on the cylindrical part 2-5, and the rotating motor 2-7 is fixedly installed on the T-shaped screw part. On the shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com