Belt conveyor capable of preventing lateral-swing impact

A belt conveyor and anti-side technology, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as left and right swing of the weight, accidents, and tilting of the weight under force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

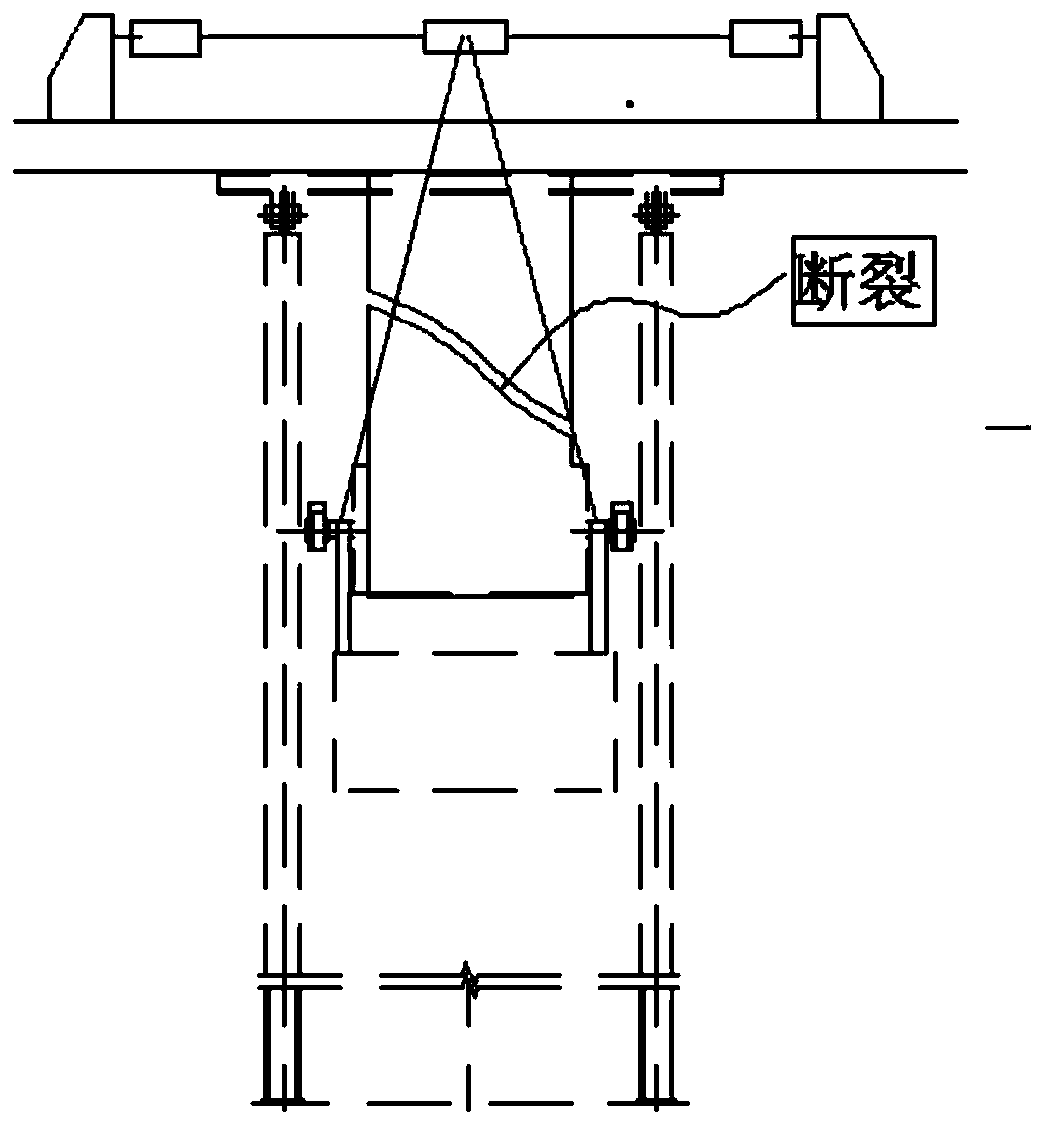

Problems solved by technology

Method used

Image

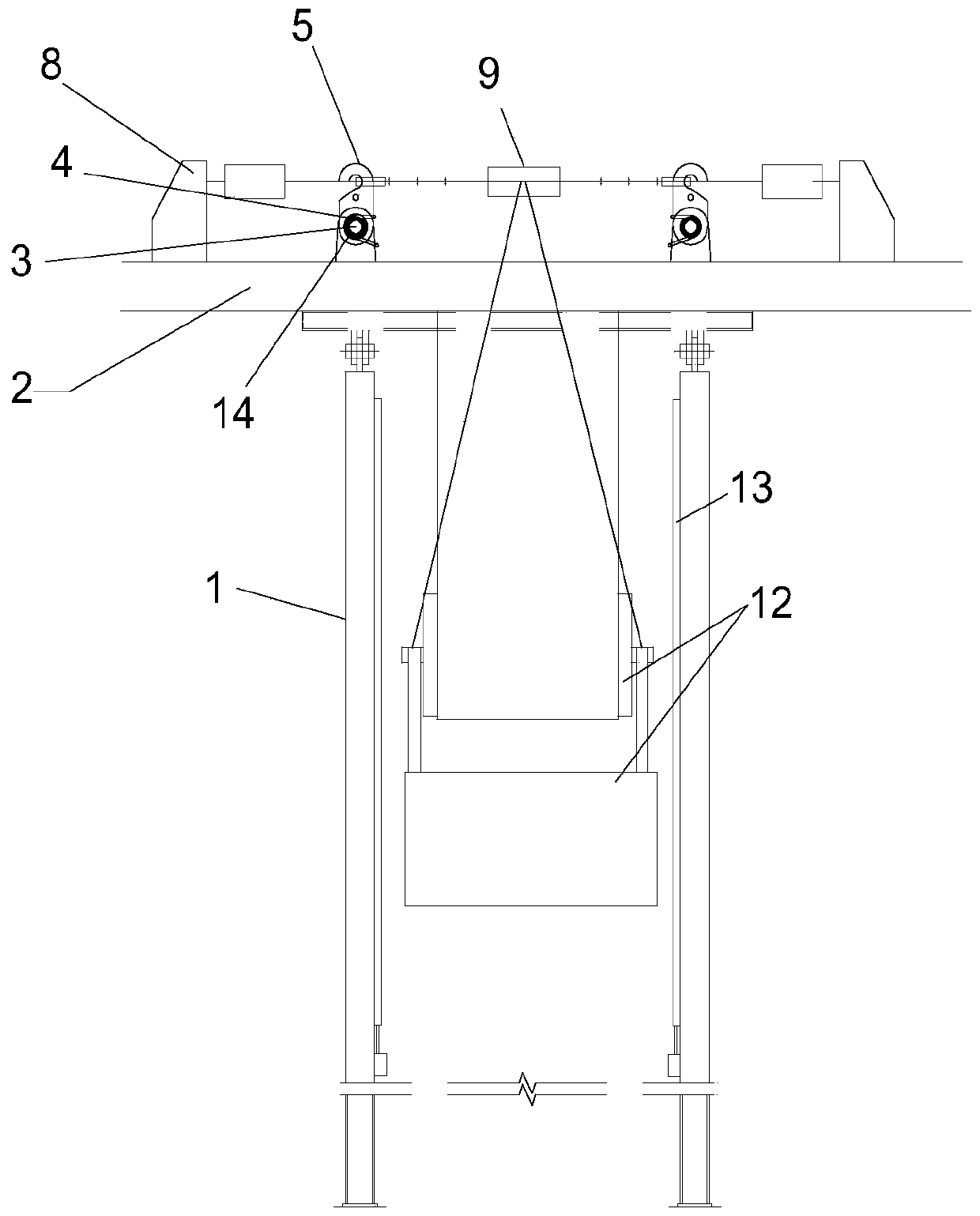

Examples

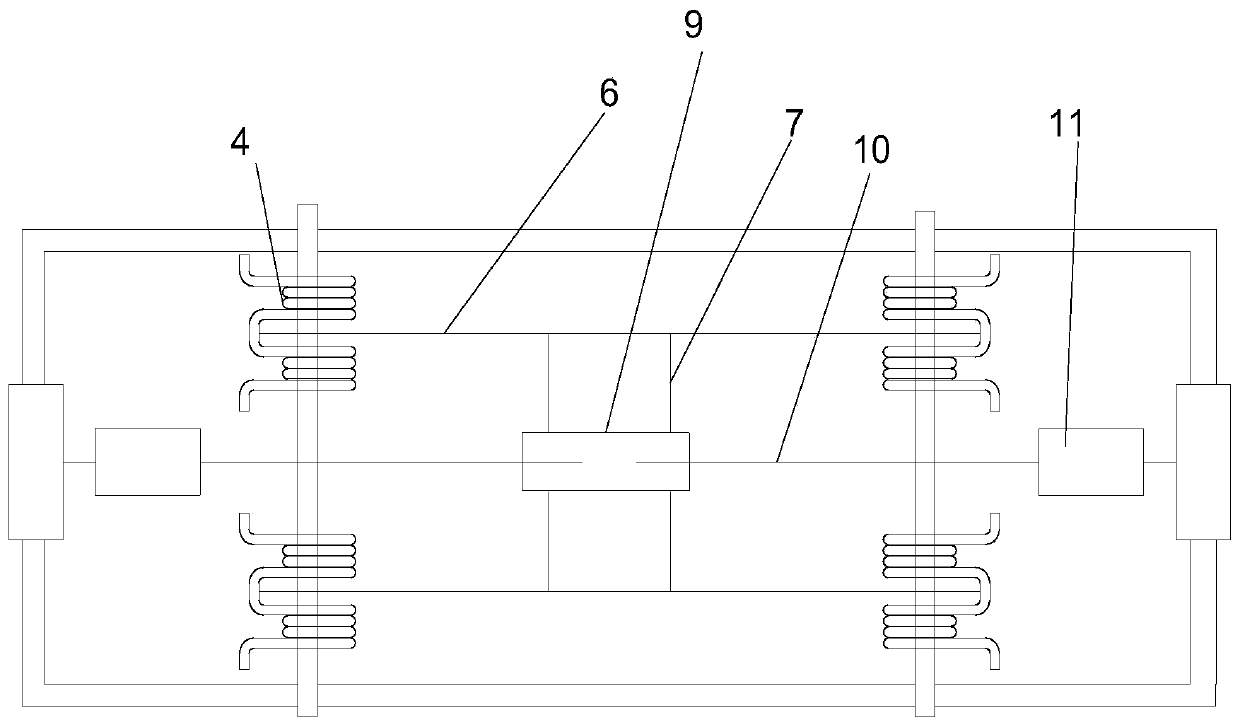

Embodiment 2

[0034] like Figure 4 As shown, on the basis of Embodiment 1, the adhesive tape fracture sensing device is the tension sensor 15 connected to the third connection line 10 . That is, whether the adhesive tape is broken by the tension sensor 15, and the air pump is controlled.

Embodiment 3

[0036] like Figure 5 As shown, on the basis of Embodiment 1, the adhesive tape fracture sensing device includes a helical coil 16 arranged on the side of the support structure 1; the helical coil 16 is electrically connected to an ammeter 20 to form a loop, and is arranged along the height direction of the support structure 1; An airbag 13 is installed between the speed measuring sensors 16; the airbag 13 communicates with a main pipe 18 through a branch pipe 17, the main pipe 18 communicates with the inflator 14, the branch pipe 17 is installed on the solenoid valve 19, and the ammeter 20 communicates with the solenoid valve 19 and the inflator 14; Magnets that cooperate with the ammeter 20 are installed on both sides of the weight roller 12 .

[0037] In this way, when the weight roller 12 moves up and down, the helical coil 16 is cut by the magnetic force, and the ammeter 20 generates an induced current. When the tape breaks, the hammer roller 12 has a sharply reduced spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com