Aluminum alloy substrate for magnetic recording medium, substrate for magnetic recording medium, magnetic recording medium, and hard disk drive

A technology for magnetic recording media and aluminum alloy substrates, which is used in magnetic recording, data recording, recording information storage, etc., and can solve problems such as difficulty in reading hard disk drives stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、 comparative example 1~5

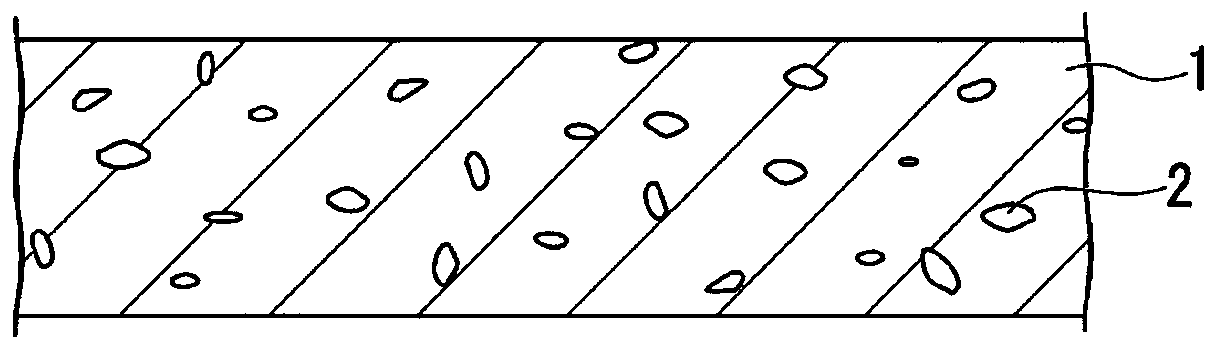

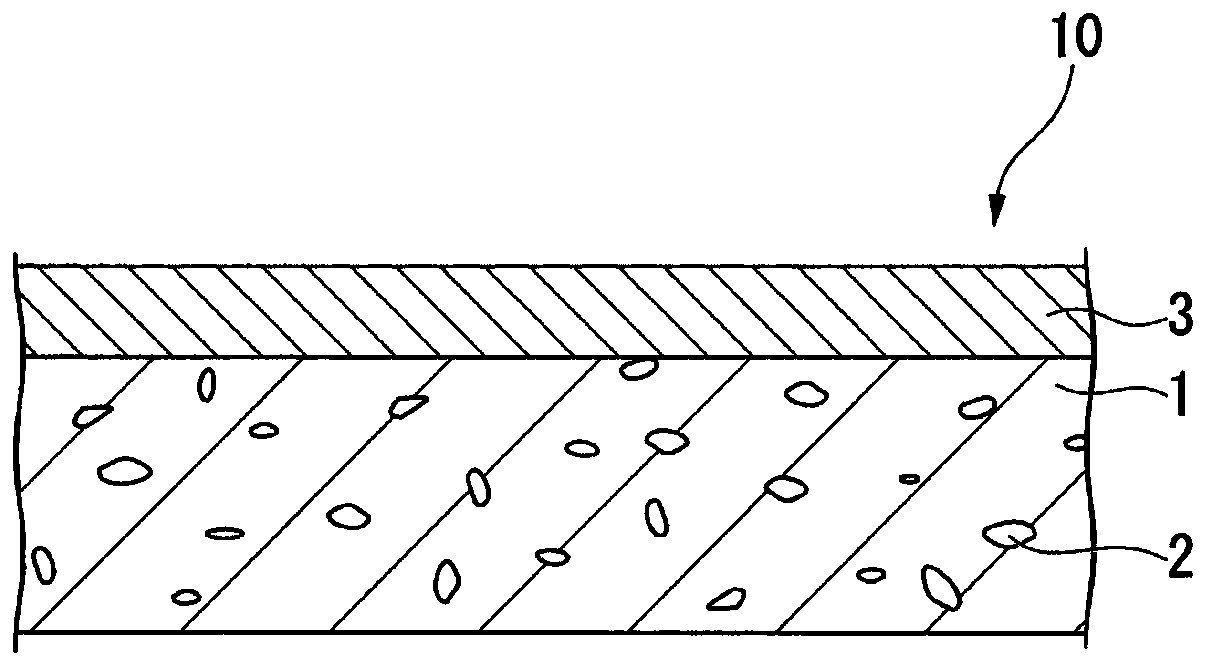

[0101] [Aluminum alloy plate]

[0102] As Al raw materials, pure Al lumps, Si, Fe, Mn, Cu, Mg, Zn, Sr, Zr, Ti, Ni, and Cr were prepared. In addition, each raw material of pure Al bulk, Si, Fe, Mn, Cu, Mg, Zn, Sr, Zr, Ti, Ni, and Cr was prepared with a purity of 99.9% by mass or more.

[0103] The prepared raw materials of each element were weighed so that the composition after casting would be the composition shown in Table 1 below, and they were melted at 820° C. in the air to prepare alloys 1 to 3. The obtained alloys 1 to 3 were fabricated into aluminum alloy ingots using a direct chill casting method (DC casting method). Next, the obtained aluminum alloy ingot was held at 460° C. for 2 hours to perform a homogenization treatment. Thereafter, rolling was performed to obtain a plate material with a thickness of 0.50 mm. In Examples 1 to 4 and Comparative Examples 1 to 5, in order to change the average number and average particle size of the coarse crystal grains of the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap