Nuclear power plant buried pipe detection test piece

A test piece and buried pipe technology, which is applied in the field of nuclear power plant buried pipe detection, can solve the problems of single prefabricated defects in the detection test piece and the inability to truly simulate the detection object.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

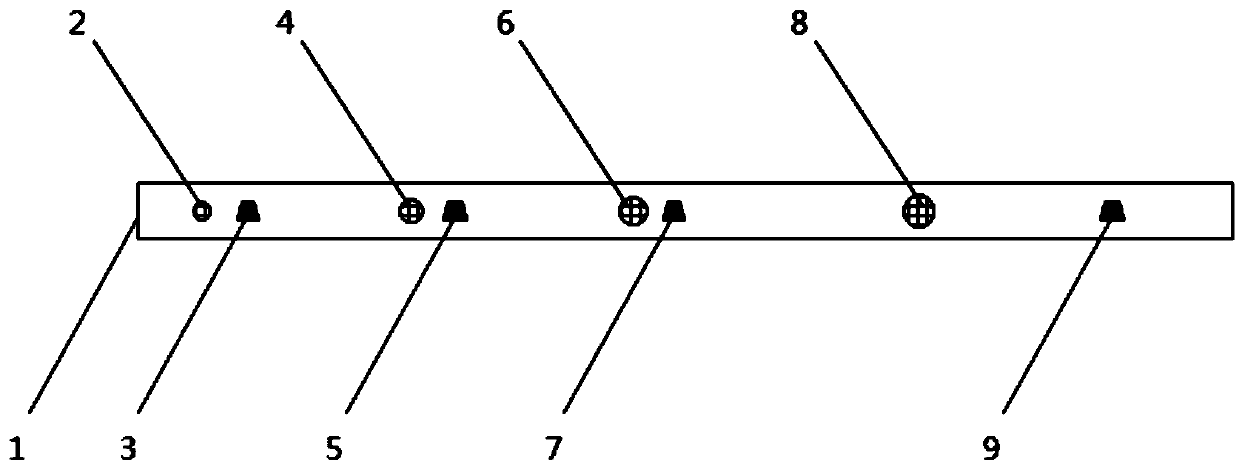

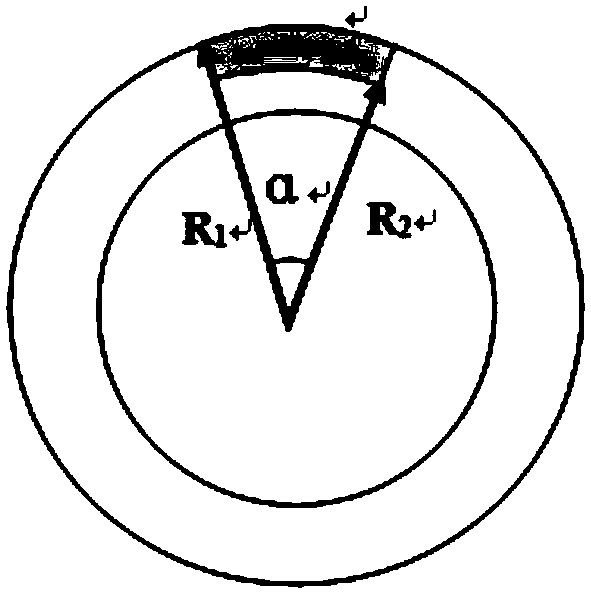

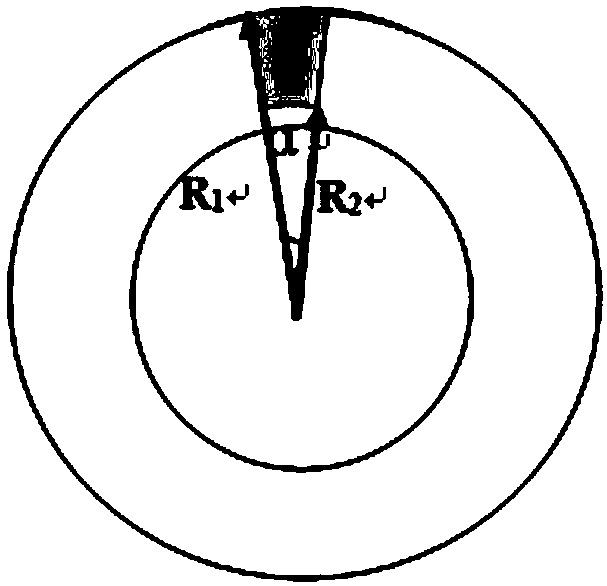

[0025] Such as figure 1 As shown in -4, a test piece for the detection of buried pipes in nuclear power plants is a pipe fitting with a length of 30 m and an anti-corrosion layer. The anti-corrosion layer defects and pipe body defects are prefabricated on the pipe fittings. The circle in the figure represents the defect of the anti-corrosion layer, the text in the figure describes the position and size of the defect, the trapezoid represents the defect of the pipe body, and the text in the figure describes the size of the defect. The figure is only a design schematic diagram. The actual test processing needs to make multiple similar test pieces, and the size and shape of the pipe body defects are different, which is convenient for comparative tests.

[0026] The anti-corrosion layer defects are designed four along the direction of the pipeline on the pipeline, and the size of the anti-corrosion layer defects is 6.5cm 2 、20cm 2 、50cm 2 、100cm 2 , the distance between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com