Measuring system and measuring method considering focusing and leveling and precision alignment

A measurement system, focusing and leveling technology, applied in the field of lithography machines, can solve the problems of long production time, high space occupancy rate of lithography machines, and low yield of lithography machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the device of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

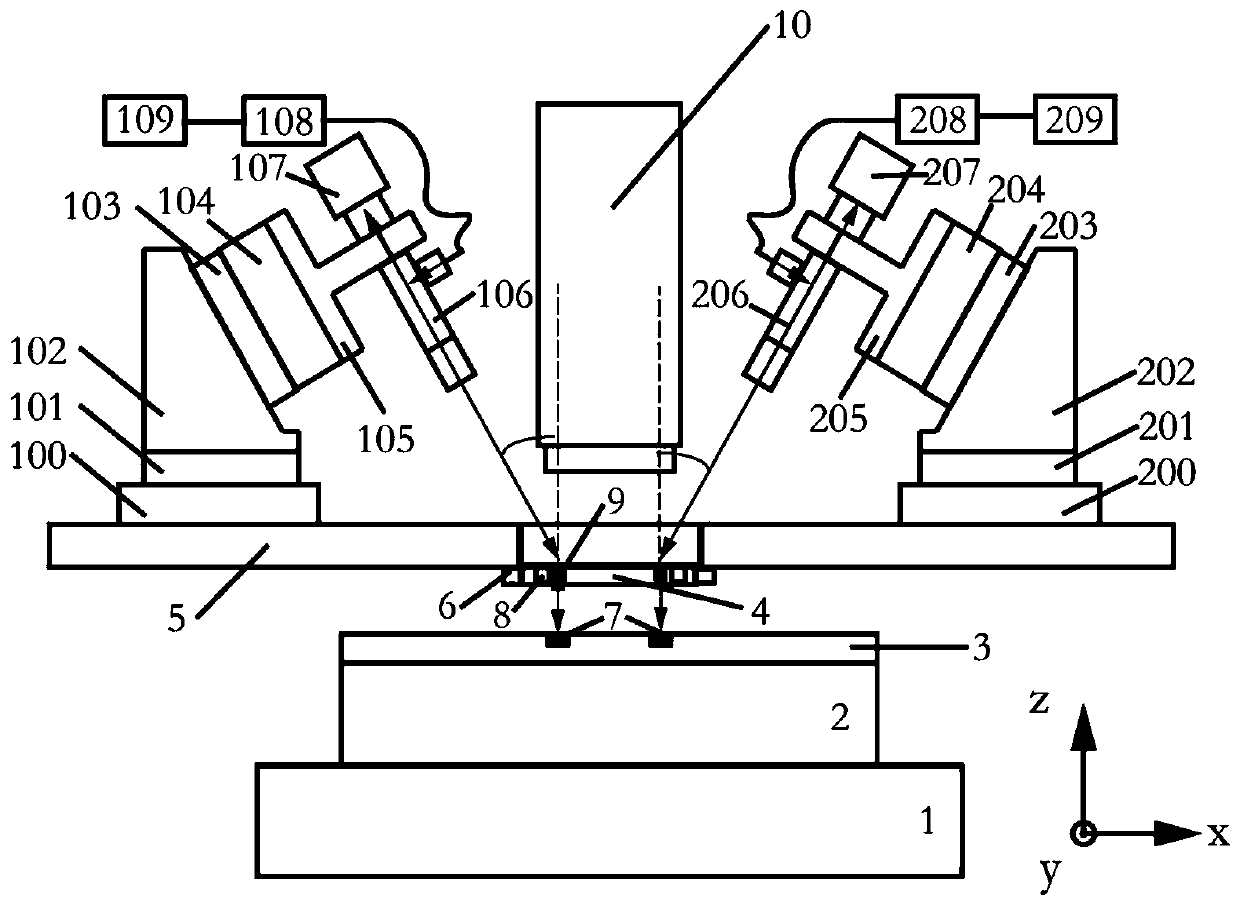

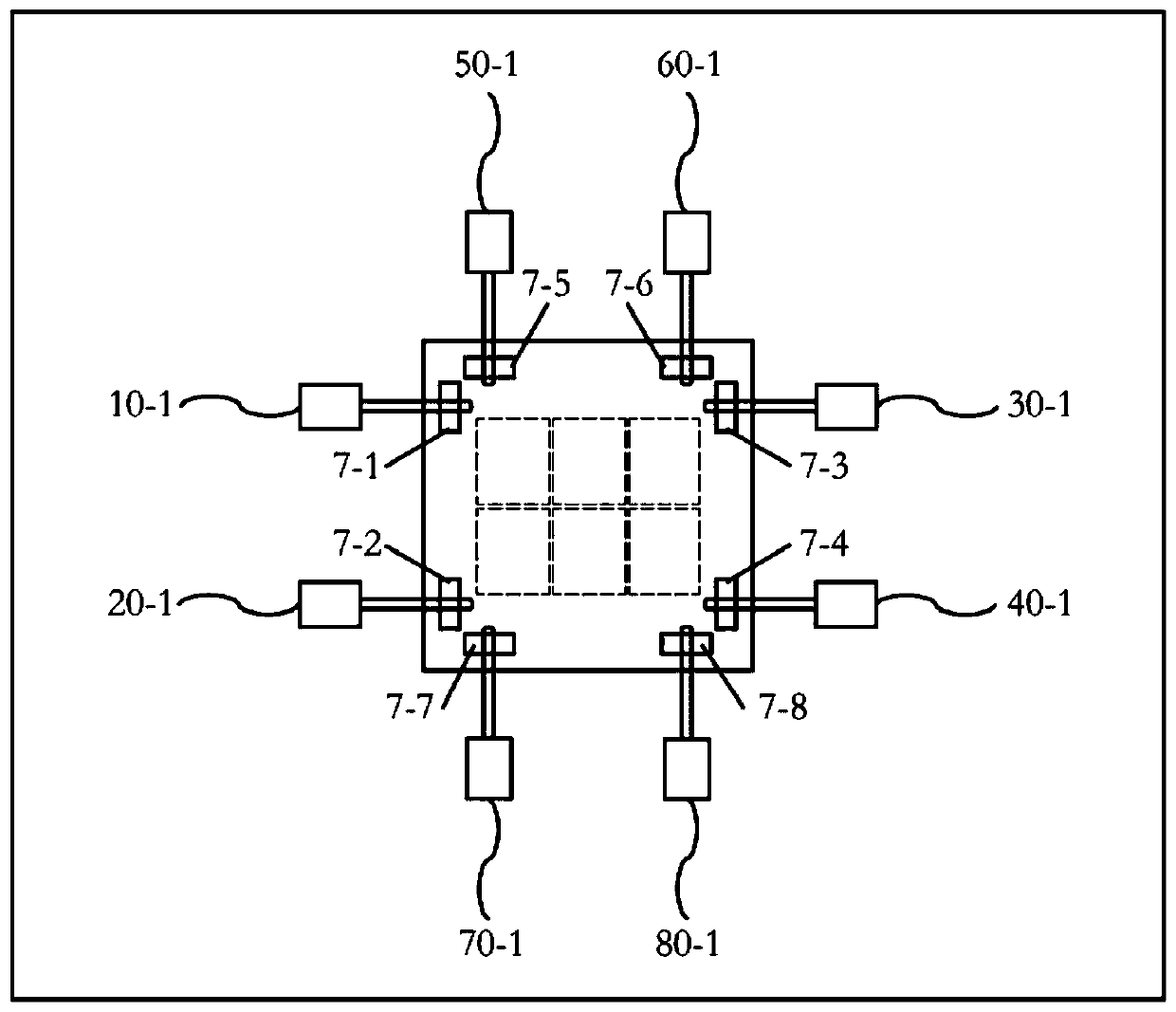

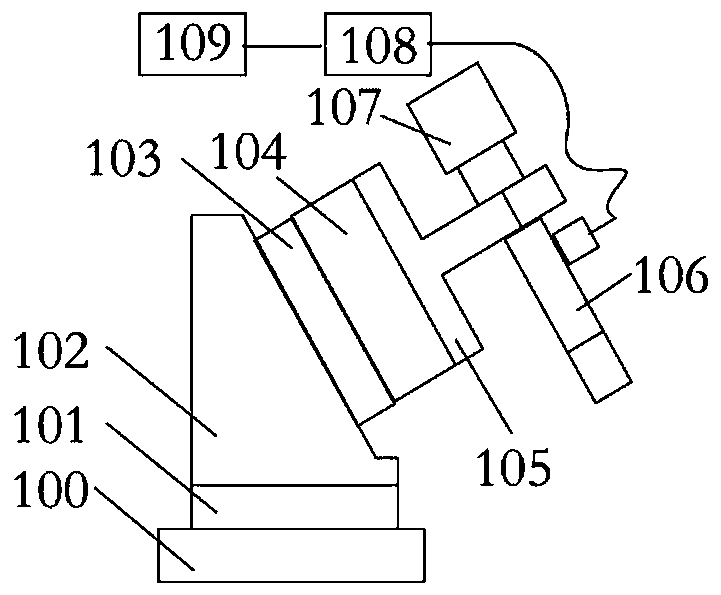

[0025] refer to figure 1 , the measurement system includes a six-degree-of-freedom nano-motion stage 1; a film-supporting stage 2, which is installed on the six-degree-of-freedom nano-motion stage 1; a silicon wafer 3 to be exposed; an exposure mask 4, which is fixed by a mask holding device 6; Substrate 5; mask holding device 6, fixed on the main substrate 5; alignment mark 7 on the substrate; gap measurement mark 8 on the mask; alignment mark area 9 on the mask; illumination source lens 10; 1. The second X\Y axis displacement table 100\200; the first and second Tz axis rotation table 101\201 are respectively installed on the first and second X\Y axis displacement table 100\200; the first and the second Two inclined adapter plates 102\202 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com