Preparation method and application of casein sodium-polyglycerol fatty acid ester complex

A technology of fatty acid ester and sodium caseinate, which is applied in the application, oil-containing food ingredients, non-active ingredients of polymer compounds, etc., can solve the problems of poor stability of sodium caseinate emulsion, and achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

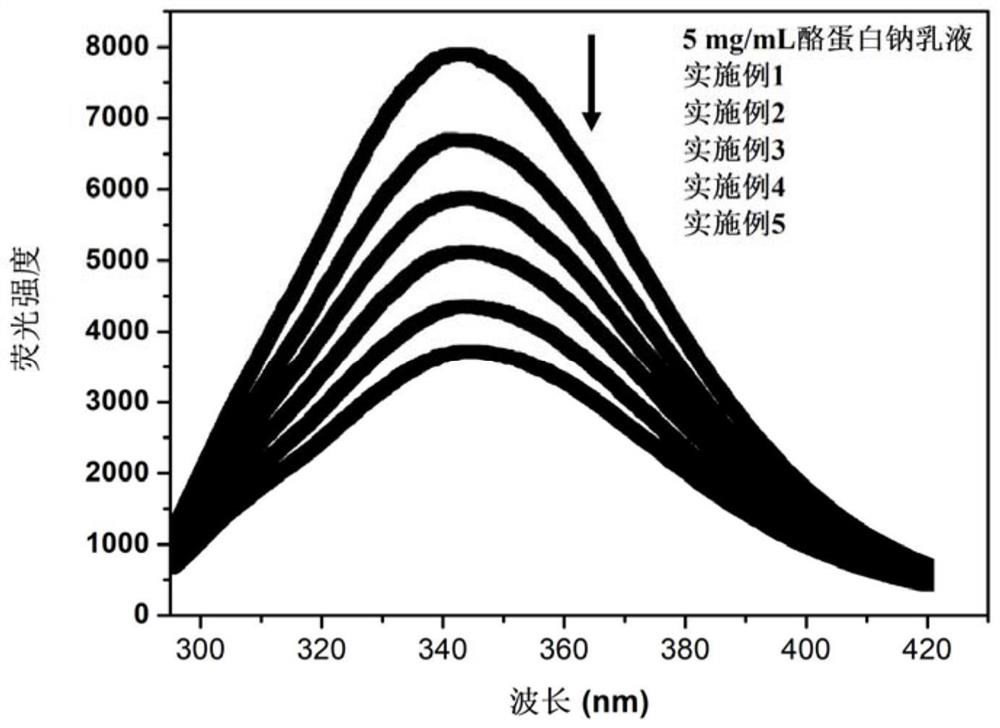

[0030] In view of this, the present invention proposes a kind of preparation method of casein sodium-polyglycerol fatty acid ester compound, the preparation method of described casein sodium-polyglycerol fatty acid ester compound comprises the following steps:

[0031] Step S100, mixing and stirring sodium caseinate, polyglycerol fatty acid ester and water to form a sodium caseinate-polyglycerol fatty acid ester complex.

[0032] Polyglycerol fatty acid ester is a new type of emulsifier with natural source, good biodegradability and high safety. , dispersion and stability, etc., can be purchased in the market. In this example, sodium caseinate, polyglycerol fatty acid ester and water are mixed, and the lipophilicity of fatty acid is used to interact with sodium caseinate to form an aqueous dispersion of sodium caseinate-polyglycerol fatty acid ester complex , in the sodium caseinate-polyglycerol fatty acid ester complex, on the one hand, due to intermolecular interactions, th...

Embodiment 1

[0048] Weigh 1.2g sodium caseinate and dissolve it in 30mL distilled water to obtain a sodium caseinate solution with a concentration of 40mg / mL, and adjust the pH to 7.0; in addition, weigh 0.6g decaglycerol monooleate and dissolve it in 30mL distilled water, A decaglycerol monooleate solution with a concentration of 20 mg / mL was obtained, and the pH was adjusted to 7.0. Take 1mL sodium caseinate solution and 1mL decaglycerol monooleate solution and mix respectively, then stir and react at 80°C for 1 hour to obtain an aqueous dispersion of caseinate sodium-decaglycerol monooleate complex (wherein, The mass ratio of sodium caseinate to decaglycerol monooleate is 2:1).

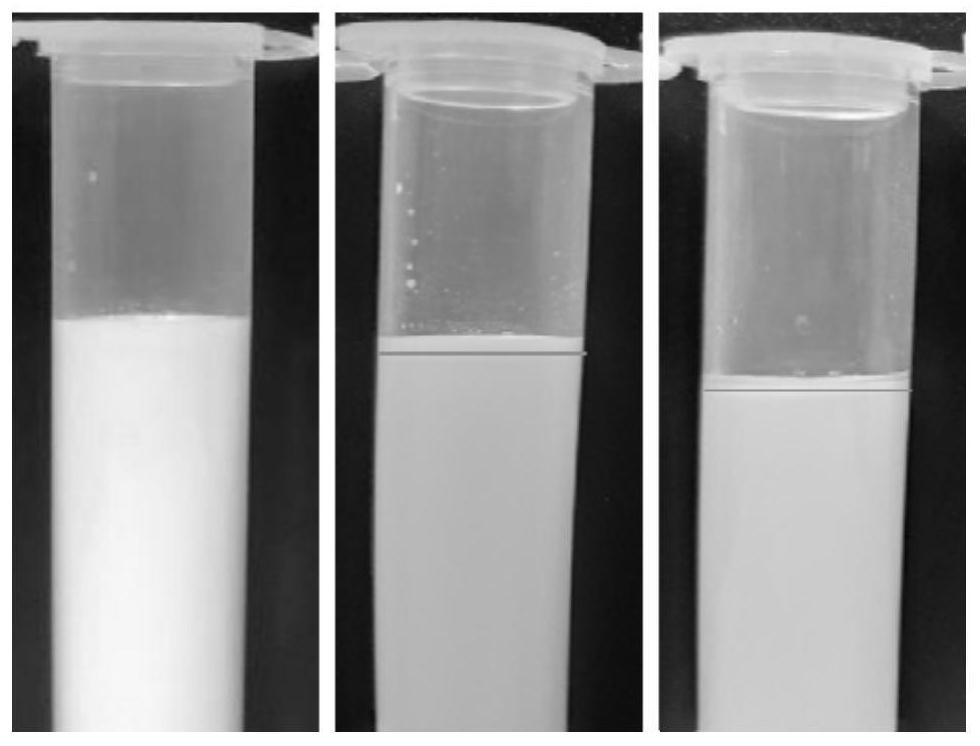

[0049] Effect verification: the aqueous dispersion of the sodium caseinate-decaglycerol monooleate complex in Example 1 was left for 90 days without particle aggregation and precipitation, indicating that the system has good stability.

Embodiment 2

[0051] Weigh 1.2g sodium caseinate and dissolve it in 30mL distilled water to obtain a sodium caseinate solution with a concentration of 40mg / mL, and adjust the pH to 7.0; in addition, weigh 1.2g decaglycerol monooleate and dissolve it in 30mL distilled water to obtain Ten polyglycerol monooleate solution with a concentration of 40mg / mL, adjust the pH to 7.0. Mix 1mL sodium caseinate solution and 1mL decaglycerol monooleate solution respectively, and then stir and react at 80°C for 1 hour to obtain an aqueous dispersion of sodium caseinate-decaglycerol monooleate complex (Wherein, the mass ratio of sodium caseinate to decaglycerol monooleate is 1:1).

[0052] Effect verification: the aqueous dispersion of the sodium caseinate-decaglycerol monooleate complex in Example 2 was left for 90 days without particle aggregation and precipitation, indicating that the system has good stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com