A kind of high peel strength flexible copper clad laminate and its manufacturing method

A technology of flexible copper clad laminates and manufacturing methods, applied in chemical instruments and methods, printed circuit manufacturing, lamination auxiliary operations, etc., can solve problems such as surface instability, large substrate thickness, and reduced dimensional stability The thickness of the foil can be customized, the thickness of the copper foil is uniform, and the effect of increasing the peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

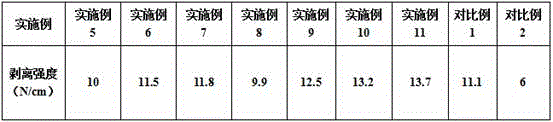

Examples

Embodiment 1

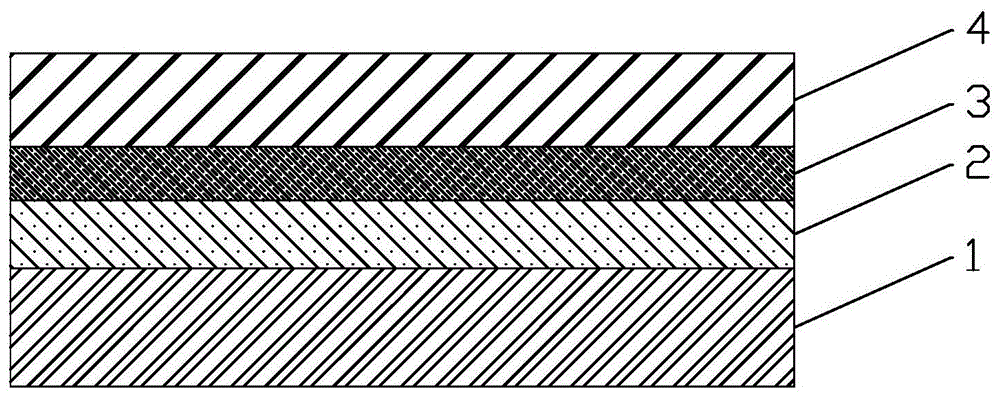

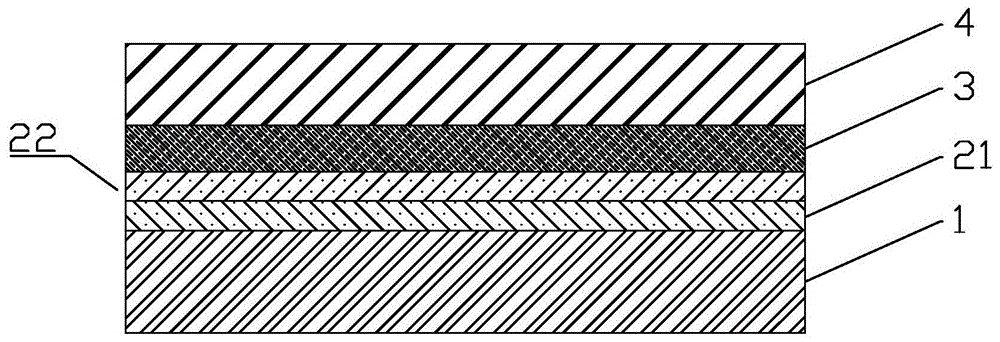

[0100] A flexible copper-clad laminate with high peel strength: comprising an organic polymer film layer, an adjustment layer is provided on at least one side of the organic polymer film layer, and more than one transition layer is provided on the other side of the adjustment layer, and the transition layer The other side is provided with a copper layer. Wherein, the adjustment layer can improve the peel strength between the organic polymer film layer and the metal layer.

[0101] A method for manufacturing a flexible copper-clad laminate with high peel strength, comprising the following specific manufacturing steps:

[0102]1) An adjustment layer is formed on at least one side of the organic polymer film layer; the thickness of the organic polymer film layer is 5-125 microns, preferably 5-50 microns; the material of the organic polymer film layer is polyimide, Polyethylene terephthalate, polybutylene terephthalate, polysulfone, polyphenylene sulfide, polyether ether ketone, ...

Embodiment 2

[0111] A flexible copper-clad laminate with high peel strength: comprising an organic polymer film layer, an adjustment layer is provided on at least one side of the organic polymer film layer, and more than one transition layer is provided on the other side of the adjustment layer, and the transition layer The other side is provided with a copper layer. Wherein, the adjustment layer can improve the peel strength between the organic polymer film layer and the metal layer.

[0112] A method for manufacturing a flexible copper-clad laminate with high peel strength, comprising the following specific manufacturing steps:

[0113] 1) Surface modification of at least one side of the organic polymer film layer; the thickness of the organic polymer film layer is 5-125 microns, preferably 5-50 microns; the material of the organic polymer film layer is polyimide Amine, polyethylene terephthalate, polybutylene terephthalate, polysulfone, polyphenylene sulfide, polyether ether ketone, po...

Embodiment 3

[0124] A flexible copper-clad laminate with high peel strength: comprising an organic polymer film layer, an adjustment layer is provided on at least one side of the organic polymer film layer, and more than one transition layer is provided on the other side of the adjustment layer, and the transition layer The other side is provided with a copper layer. Wherein, the adjustment layer can improve the peel strength between the organic polymer film layer and the metal layer.

[0125] A method for manufacturing a flexible copper-clad laminate with high peel strength, comprising the following specific manufacturing steps:

[0126] 1) An adjustment layer is formed on at least one side of the organic polymer film layer; the thickness of the organic polymer film layer is 5-125 microns, preferably 5-50 microns; the material of the organic polymer film layer is polyimide, Polyethylene terephthalate, polybutylene terephthalate, polysulfone, polyphenylene sulfide, polyether ether ketone,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com