Heat-conductive insulation filling and preparation method thereof

A heat-conducting and insulating filler and raw material technology, applied in the direction of fibrous fillers, chemical instruments and methods, semiconductor devices, etc., can solve the problems of complex preparation process, inability to balance insulation and heat conduction, etc., and achieve easy dispersion, low production cost, change Hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

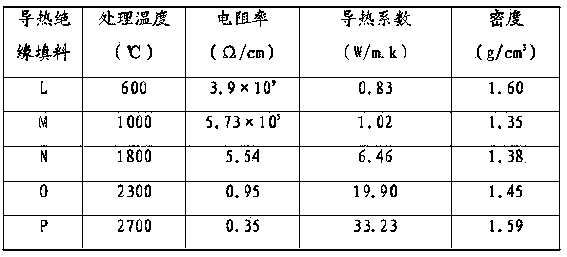

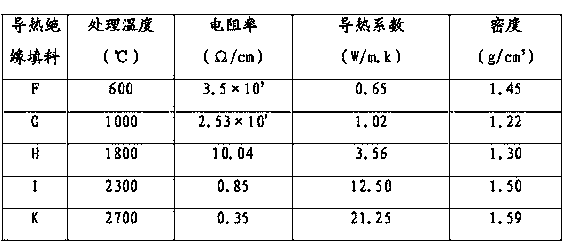

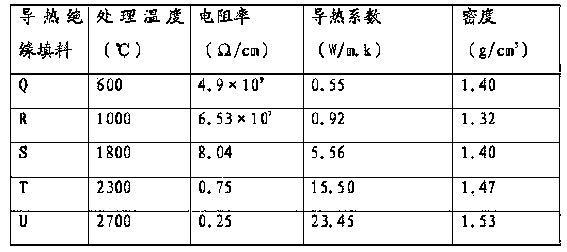

Embodiment 1

[0020] A thermally conductive insulating filler, prepared by the following method:

[0021] That is, the mesophase carbon microspheres are used as raw materials, and the intermediate product is obtained after oxidative grafting treatment at room temperature in a mixed acid solution of nitric acid and sulfuric acid with a water content of 40% for 2 hours, and then filtered, washed, and dried;

[0022] Among them, the mass ratio of the mesophase carbon microspheres to the mixed acid solution of nitric acid and sulfuric acid containing 40% water is: 1:1;

[0023] Among them, the mesophase carbon microspheres have a particle size of 1-20 μm and a volatile content of less than 10%;

[0024] The mixing mass ratio of nitric acid and sulfuric acid in the mixed acid solution of nitric acid and sulfuric acid is 1:1, and the nitric acid and sulfuric acid used are neither nitric acid nor sulfuric acid with an industrial acid concentration of 98%;

[0025] The intermediate product obtaine...

Embodiment 2

[0027] A thermally conductive insulating filler, prepared by the following method:

[0028] The intermediate product obtained after the oxidation grafting treatment was carbonized and graphitized at a high temperature of 1000° C., and the others were the same as in Example 1, and finally a thermally conductive and insulating filler B was obtained.

Embodiment 3

[0030] A thermally conductive insulating filler, prepared by the following method:

[0031] The intermediate product obtained after the oxidation grafting treatment was carbonized and graphitized at a high temperature of 1800° C. for 1 hour, and the others were the same as in Example 1, and finally a thermally conductive and insulating filler C was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com