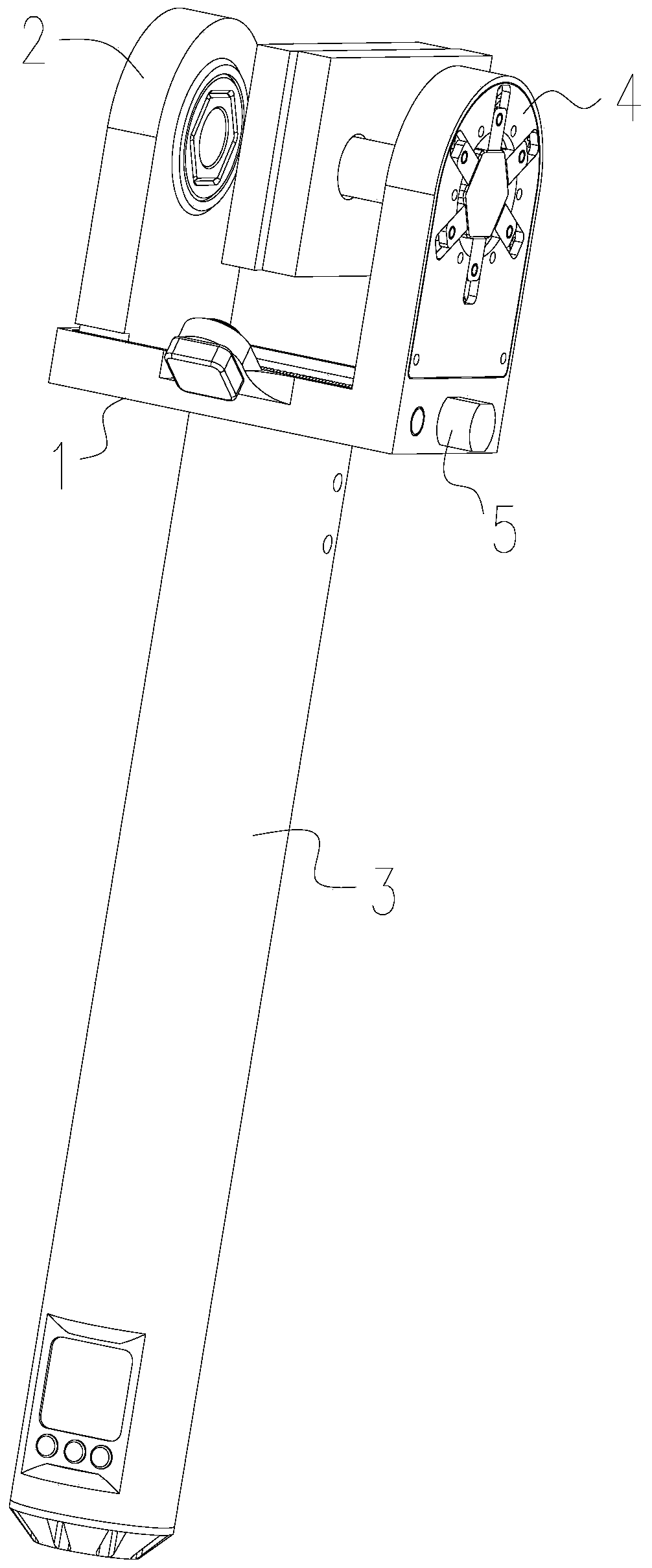

Bolt pre-tightening device for high-tension cable jumper conductor clamper

A technology of drainage wire clamp and high-voltage wire, applied in workpiece clamping device, TV, closed-circuit TV system, etc., can solve the problems of high-risk working environment and low work efficiency, and achieve the effect of small size, simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

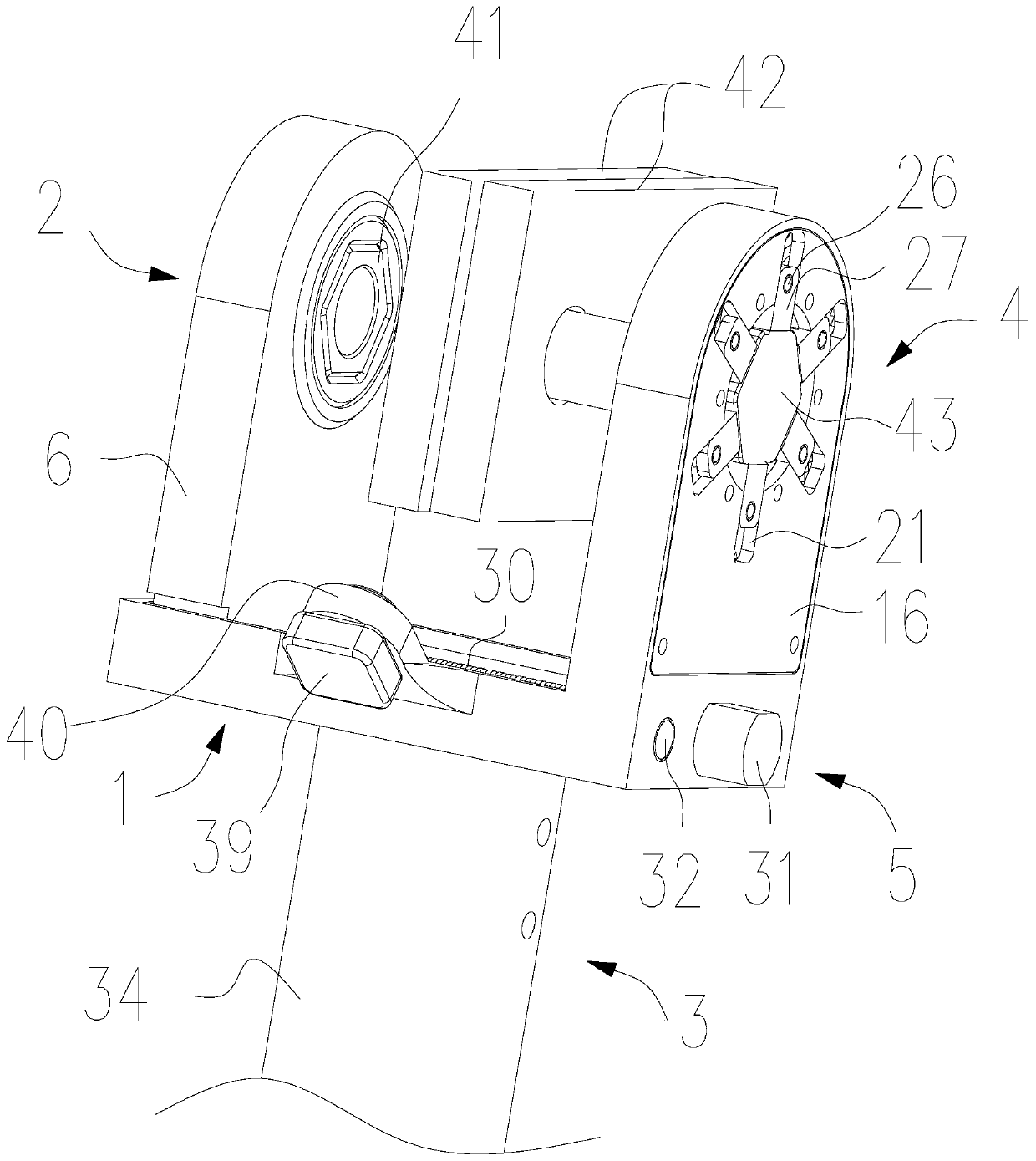

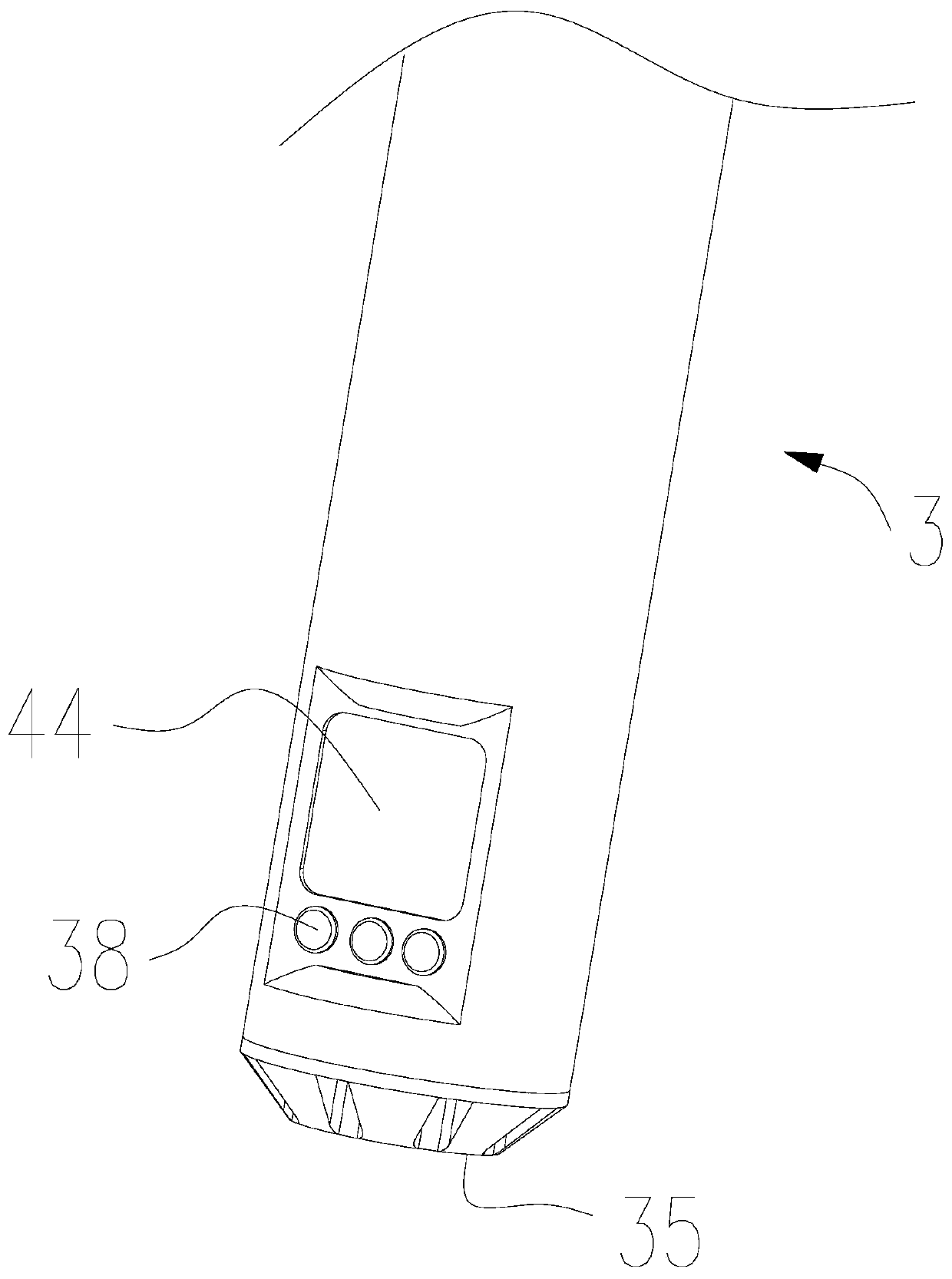

[0035] On the basis of Embodiment 1, a camera 39 is installed in the middle of the main base 1 , and a display 44 is provided outside the handle 34 , and the camera 39 and display 44 are respectively connected to the controller 37 through lines.

[0036] In this embodiment, the main base 1 is provided with a mount 40 , and the camera 39 is mounted on the mount 40 .

[0037] When the bolt pre-tightening device for high-voltage line drainage clamps according to the present invention is used, the nuts and bolt heads to be fastened are correspondingly rotated in the nut tightening mechanism and the bolt tightening mechanism, and moved to the two sides of the drainage clamps that need to be fixed. Between the two mounting plates, pass the end of the bolt through the through hole of the mounting plate, and open the device of the present invention by pressing a button, and the nut tightening mechanism will drive the nut in the rotating state to the bolt tightening mechanism under the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap