Hoisting method for engine room general section of bulk carrier and bulk carrier constructed by using hoisting method

A hoisting method and technology for bulk carriers, which are applied in safety devices, transportation and packaging, and load hanging components, etc., can solve problems such as low hoisting efficiency, and achieve the effects of improving hoisting efficiency, saving crane resources, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

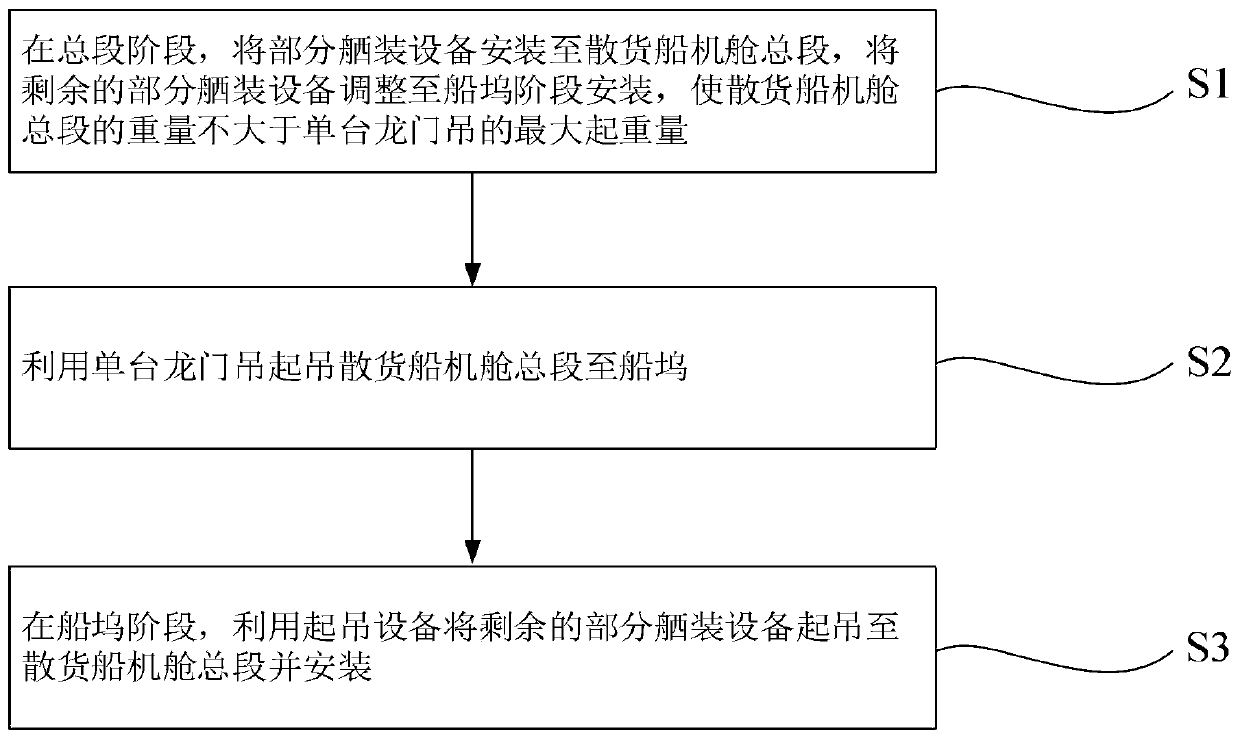

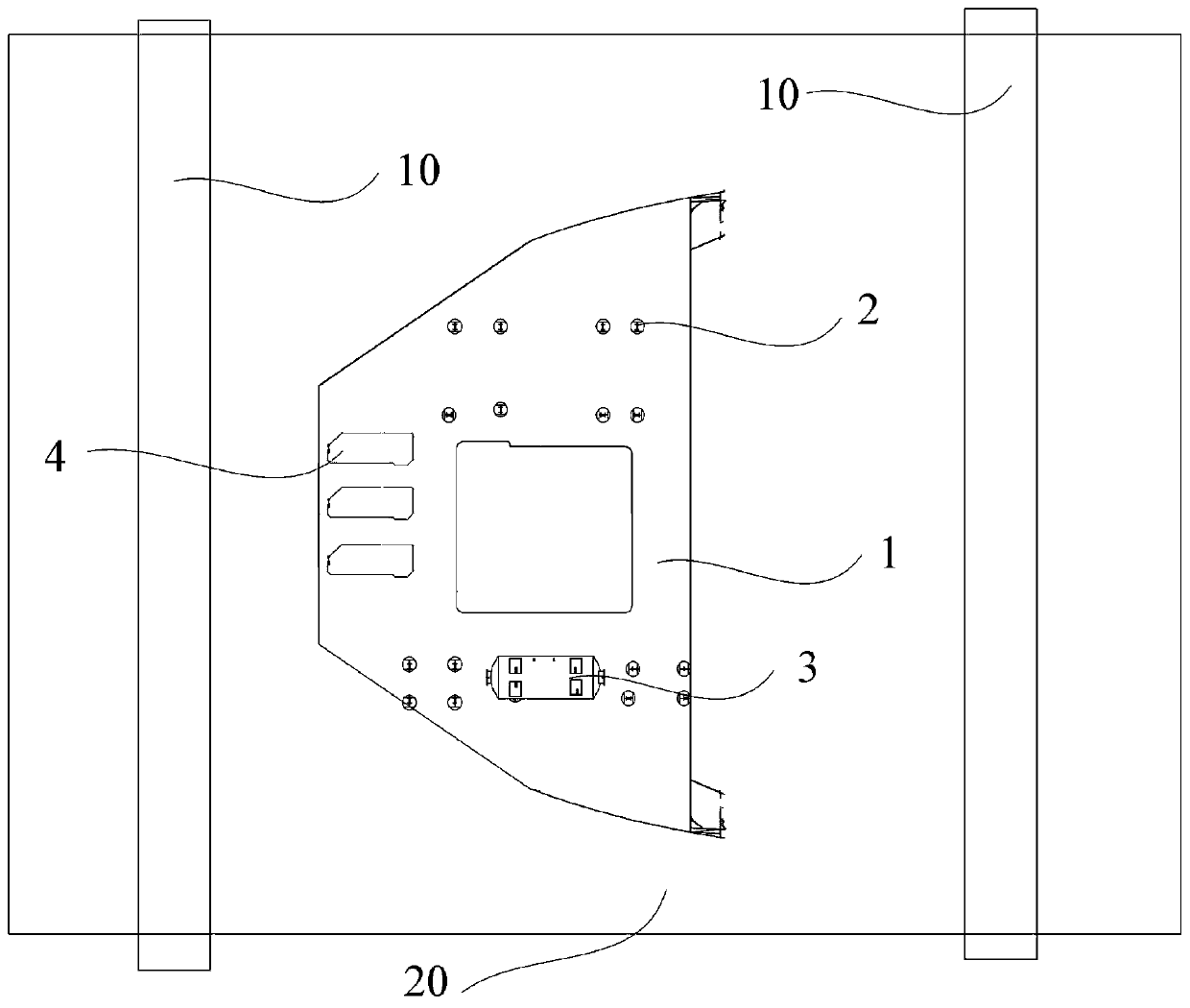

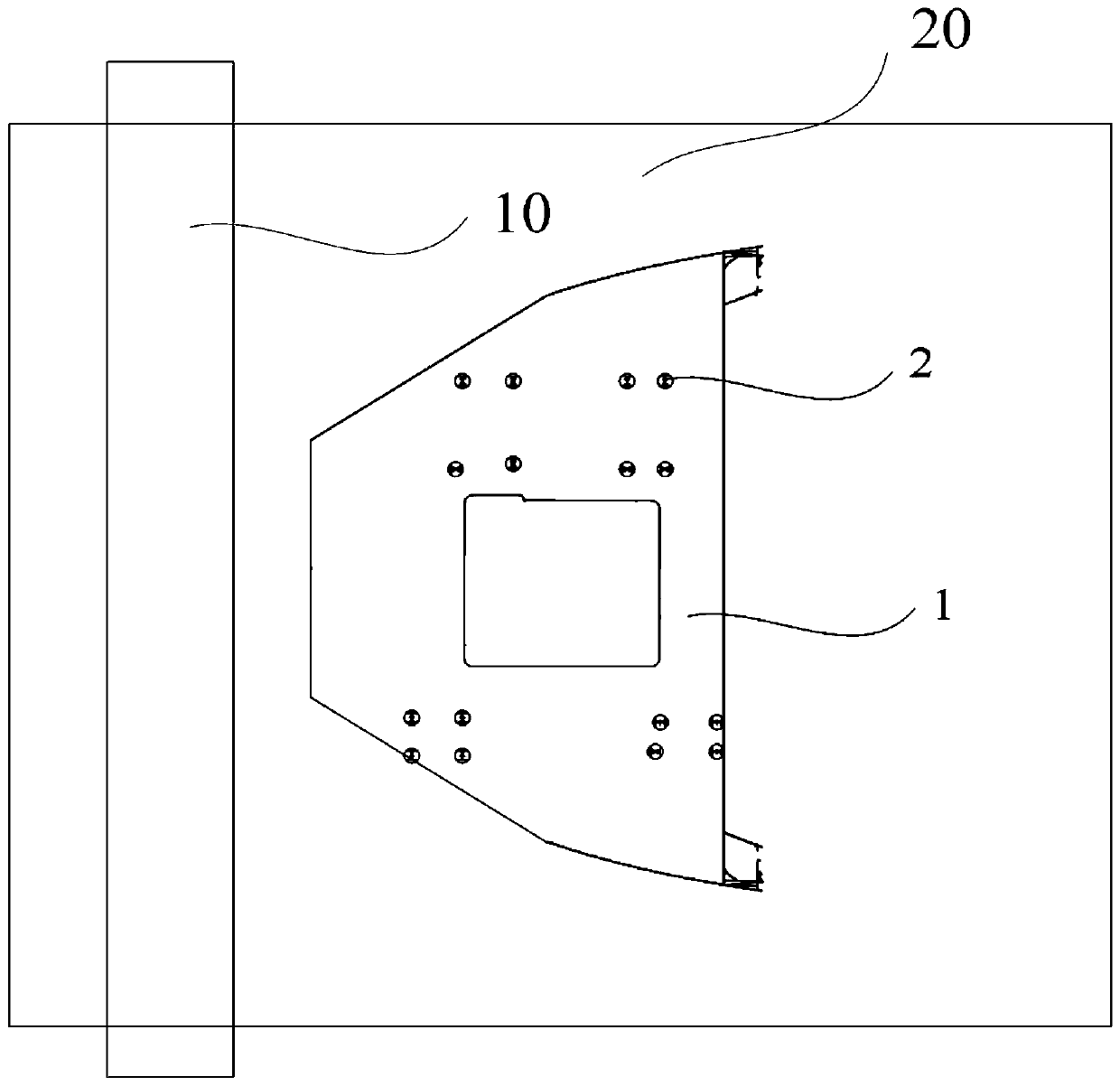

[0049] Such as Figure 1-Figure 5 As shown, the present invention discloses a hoisting method for the general section of the bulk carrier engine room, including the following steps: S1. In the general section stage, install part of the outfitting equipment to the bulk carrier engine room general section 1, and install the remaining part of the outfitting equipment The installation equipment is adjusted to the dock stage for installation, so that the weight of the general section 1 of the engine room of the bulk carrier is not greater than the maximum lifting capacity of a single gantry crane 10; S2, using a single gantry crane 10 to lift the general section 1 of the engine room of the bulk carrier to the dock 20; S3, In the docking s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com