Light-emitting pavement brick

A technology of yellow light and light-transmitting layer, applied in the field of light-emitting bricks, can solve the problems of not being able to truly play the role of traditional bricks, poor mechanical performance of light-emitting bricks, and inability to use light-emitting bricks, etc., to achieve simple installation, good warning effect, and use. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

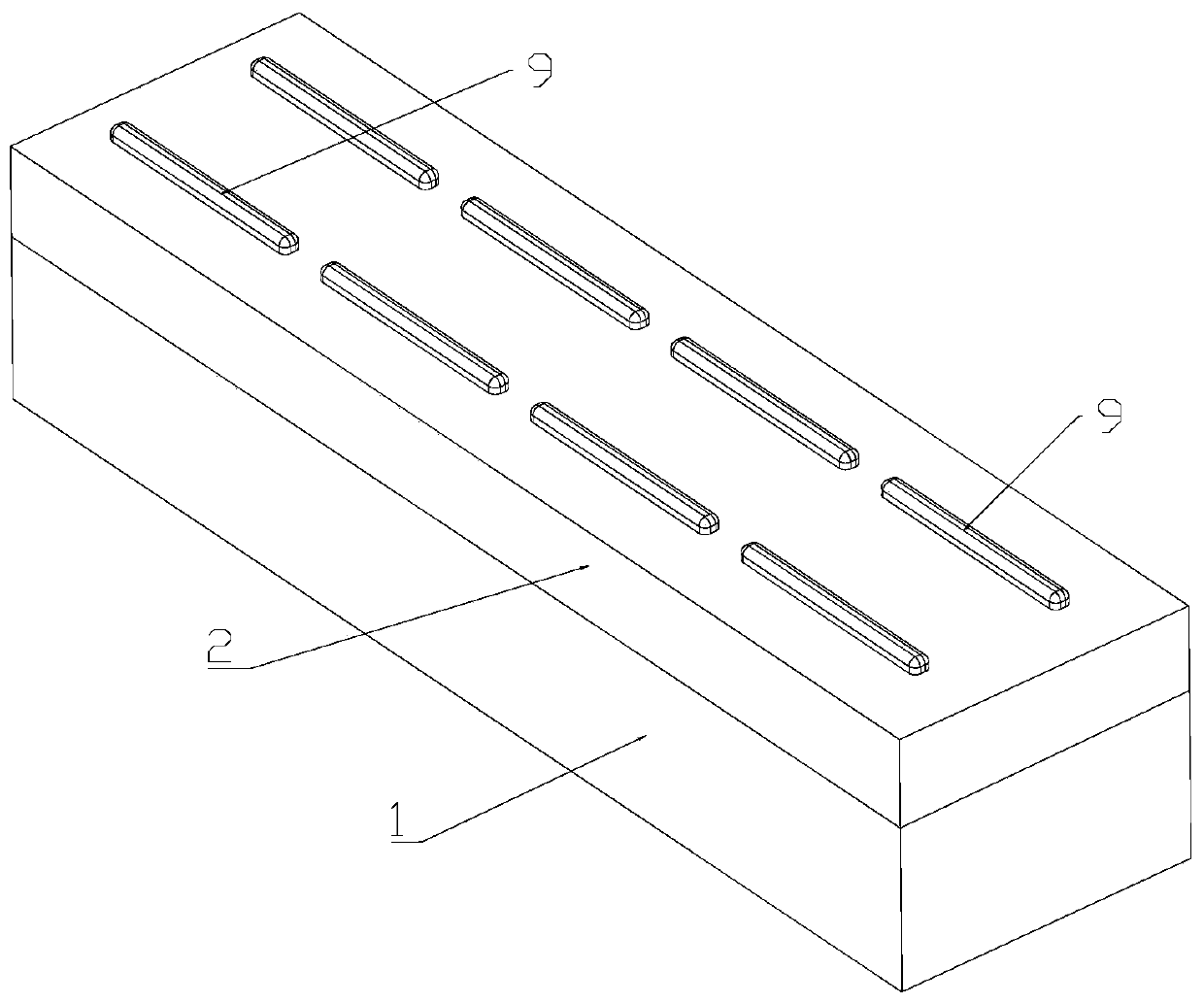

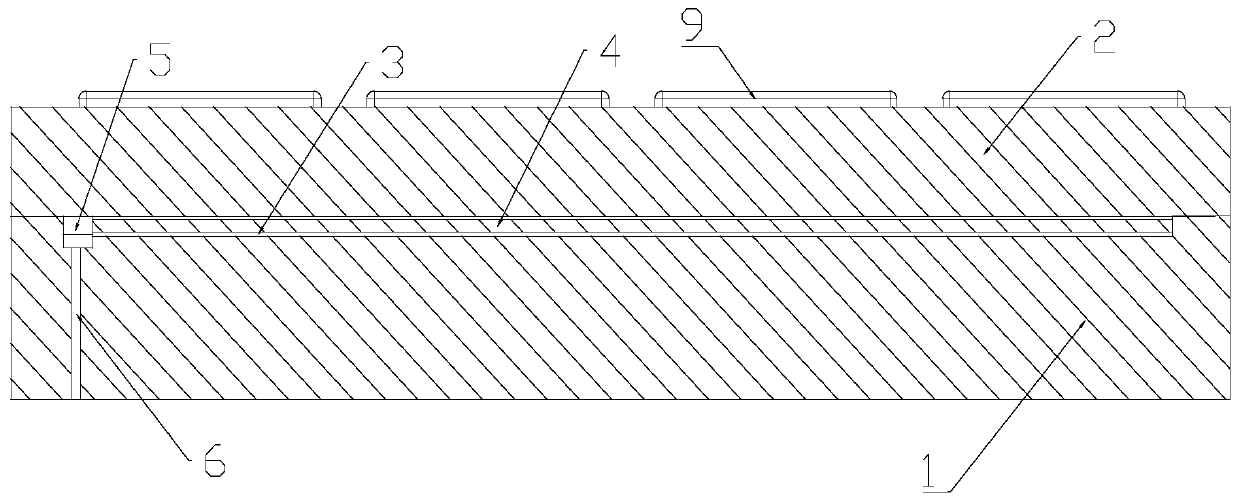

[0023] Such as Figure 1-3 As shown, a pavement luminous brick includes a base 1 made of resin concrete and a light-transmitting layer 2 made of light-transmitting quartz stone. The upper surface of the base 1 is provided with several strip-shaped Long grooves 3, light tubes 4 are respectively installed in the long grooves 3, the light-transmitting layer 2 is located above the base 1 and covers all the long grooves 3, the gap between the light-transmitting layer 2 and the base 1 One end of the base 1 is provided with a cavity 5 inside, the elongated grooves 3 communicate with the cavity 5 respectively, and the bottom of the cavity 5 is provided with a wiring connected to the lower surface of the base 1 Groove 6, the lamp tube 4 is connected to the power supply through wires, and the wires pass through the wiring groove 6.

[0024] Further, the cross section of the elongated groove 3 is an inverted triangle, and the height of the bottom of the cavity 5 is lower than the height...

Embodiment 2

[0031] Such as Figure 1-3 As shown, a pavement luminous brick includes a base 1 made of resin concrete and a light-transmitting layer 2 made of light-transmitting quartz stone. The upper surface of the base 1 is provided with several strip-shaped Long grooves 3, light tubes 4 are respectively installed in the long grooves 3, the light-transmitting layer 2 is located above the base 1 and covers all the long grooves 3, the gap between the light-transmitting layer 2 and the base 1 One end of the base 1 is provided with a cavity 5 inside, the elongated grooves 3 communicate with the cavity 5 respectively, and the bottom of the cavity 5 is provided with a wiring connected to the lower surface of the base 1 Groove 6, the lamp tube 4 is connected to the power supply through wires, and the wires pass through the wiring groove 6.

[0032] Further, the cross section of the elongated groove 3 is an inverted triangle, and the height of the bottom of the cavity 5 is lower than the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com