Cold energy recycling device for LNG gas station

A cold energy recovery and gasification station technology, which is applied in steam recovery, steam engine installations, lighting and heating equipment, etc., can solve the problems of brine solidification and lack of technical solutions, so as to save resources, optimize energy utilization, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

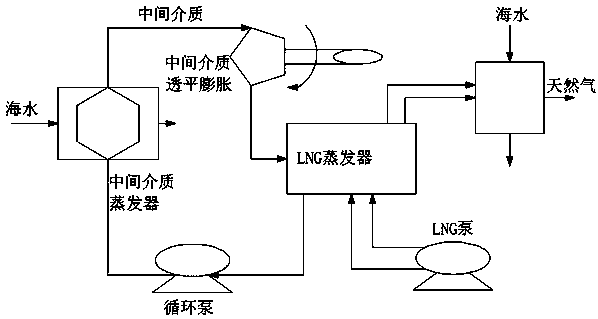

[0018] This embodiment discloses as figure 1 A cold energy recovery and utilization device for an LNG gasification station is shown, which is characterized in that the device includes an LNG evaporator and an intermediate medium evaporator, and the LNG evaporator circulates natural gas to the intermediate medium for evaporation through a circulation pump The intermediate medium evaporator attaches the cold energy in the natural gas to the intermediate medium through the intermediate medium, and the intermediate medium passes through the heat exchanger to process the natural gas into a high-pressure normal temperature gas and then transmits it to the intermediate medium turbine to expand and drive the engine generate electricity.

[0019] The LNG evaporator is connected to raw natural gas through an LNG pump, and the natural gas is separated from seawater through the LNG evaporator.

[0020] The intermediate medium turbine returns the natural gas extracted from the cold energy...

Embodiment 2

[0026] In this embodiment, the device in Example 1 is reused, and the cold energy of LNG is applied step by step. Shallow cooling is mainly used to build cold storage, medium cooling is mainly used to make ice, ice skating rinks and ski resorts, and deep cooling is mainly used Cryogenic grinding from air separation, etc. If you want to maximize the utilization rate of cold energy, you must use it in stages to maximize the application of energy.

[0027] In terms of efficient utilization of LNG cold energy, it is generally believed that the temperature difference power generation between the environment and LNG is the main way of utilization. If it is analyzed according to exergy economics, it can be known that only by using a large amount of electric energy can natural gas be liquefied, and in the liquefaction process, it is then completed by the cryogenic process (consuming about 8_50.OkW-h / t), however, Carnot’s theorem proposes that when a temperature difference of about 18...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap