Tool assembly for rapid inspection of sliding rail

A slide rail and fast technology, applied in the direction of adopting mechanical devices, measuring devices, mechanical measuring devices, etc., can solve the problems of large error, low efficiency, slow speed, etc., and achieve the effect of simple structure, high detection efficiency and convenient fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

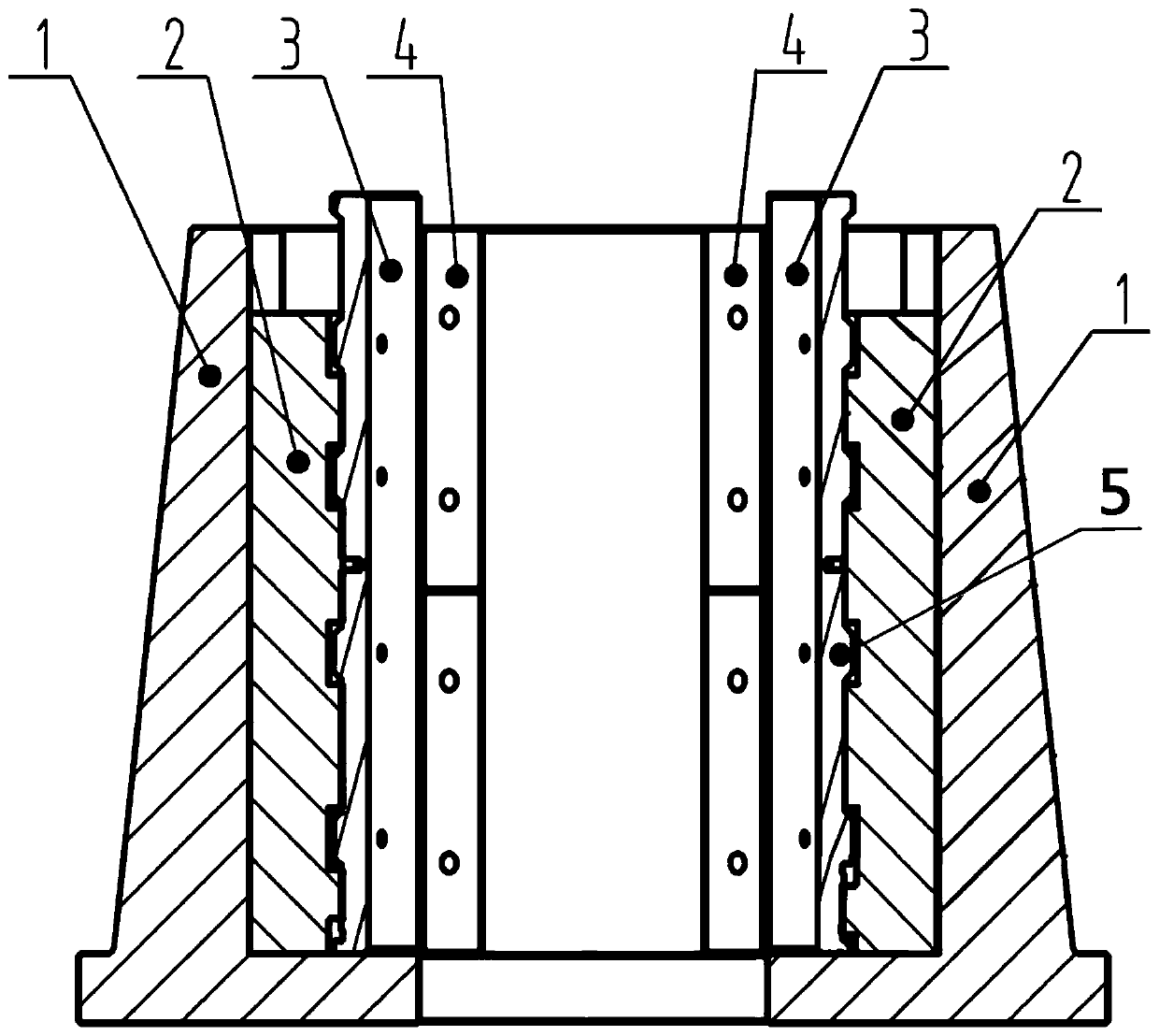

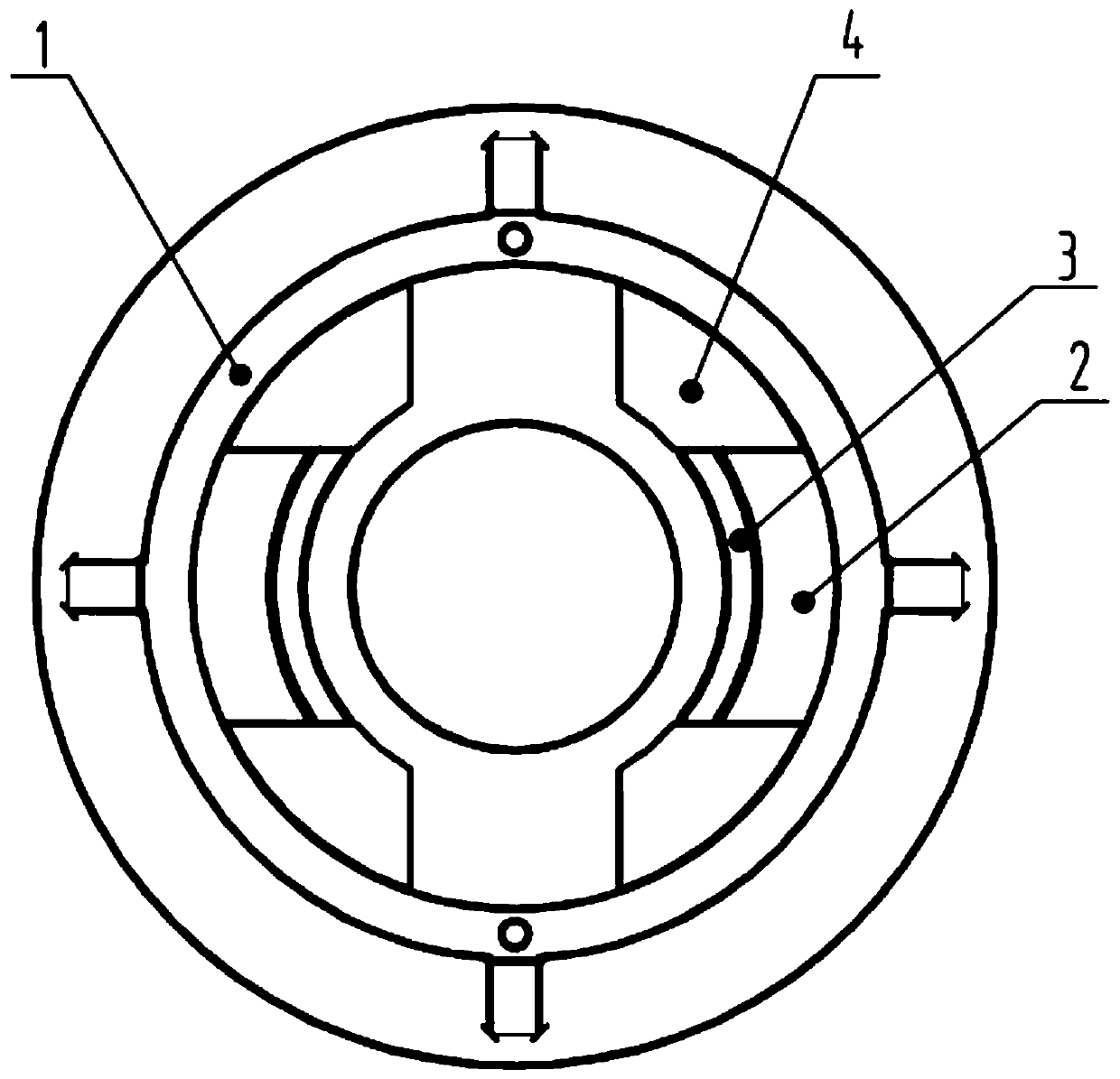

[0017] Such as figure 1 and 2 As shown, a tooling assembly for rapid inspection of slide rails includes a frame 1, a dial indicator holding block 4 and a magnet 2, and the frame 1 is used to carry and fix the slide rail 3, the dial indicator holding block 4 and the magnet 2. Magnet 2, the magnet 2 is an electromagnet, the inside of the frame 1 is provided with a mounting groove, the magnet 2 and the slide rail 3 are installed in the mounting groove, and the dial indicator holding block 4 is used to detect the support of the slide rail. The tooling assembly is simple in structure, easy to process and easy to use, and the number of slide rails 3 to be detected at a single time is larger than that of the prior art, and the detection efficiency is high.

[0018] There are 2 magnets 2 and 2 mounting slots, and the 2 mounting slots are arranged oppositely, and there is 1 magnet 2 in each mounting slot. Each magnet 2 absorbs one slide rail 3 respectively, and the number of slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com