Metal detection device

A metal detection and transmitting coil technology, applied in measurement devices, geophysical measurement, radio wave measurement systems, etc., can solve the problems of large volume, offset of balance point, poor consistency control of detection effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

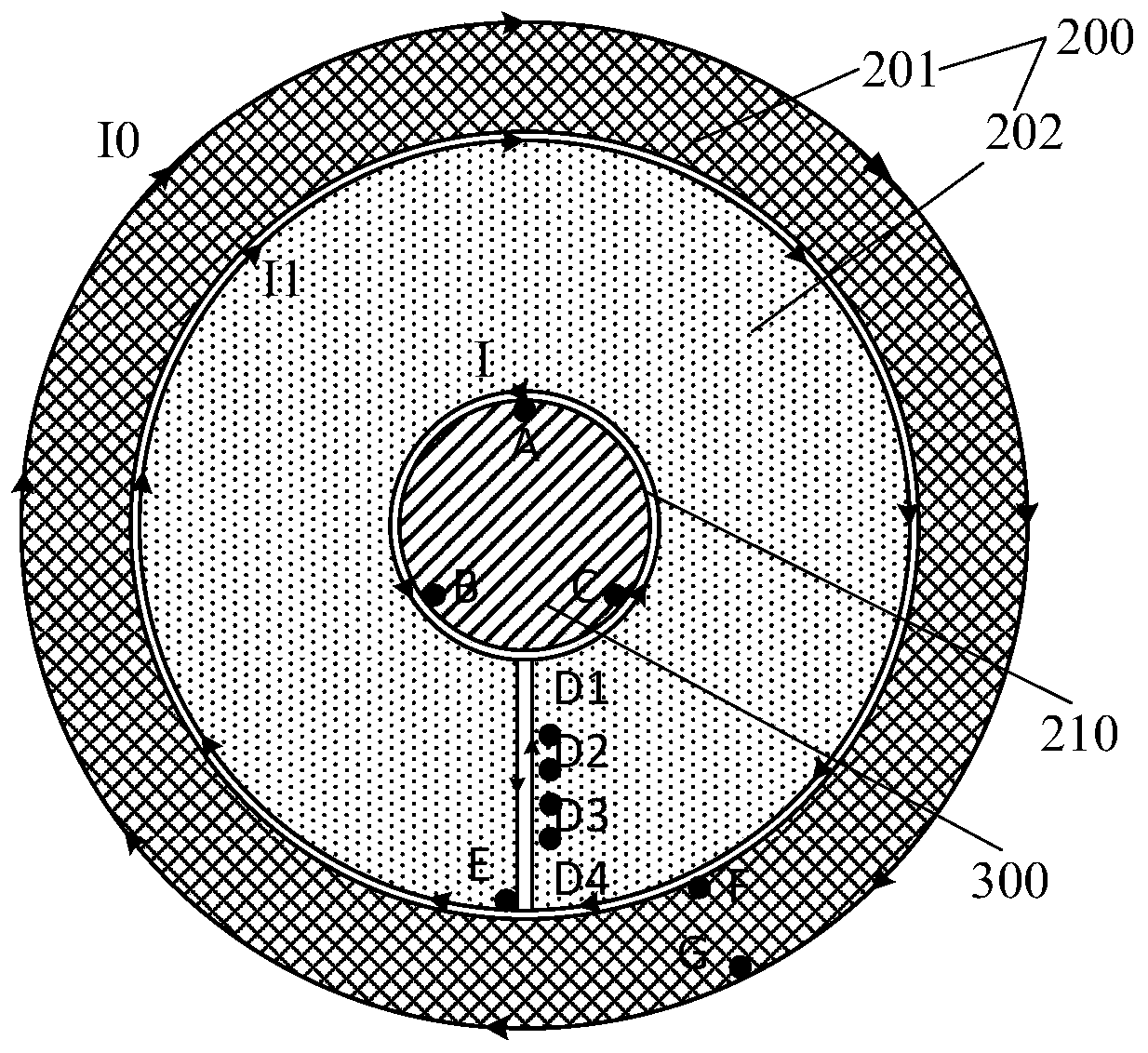

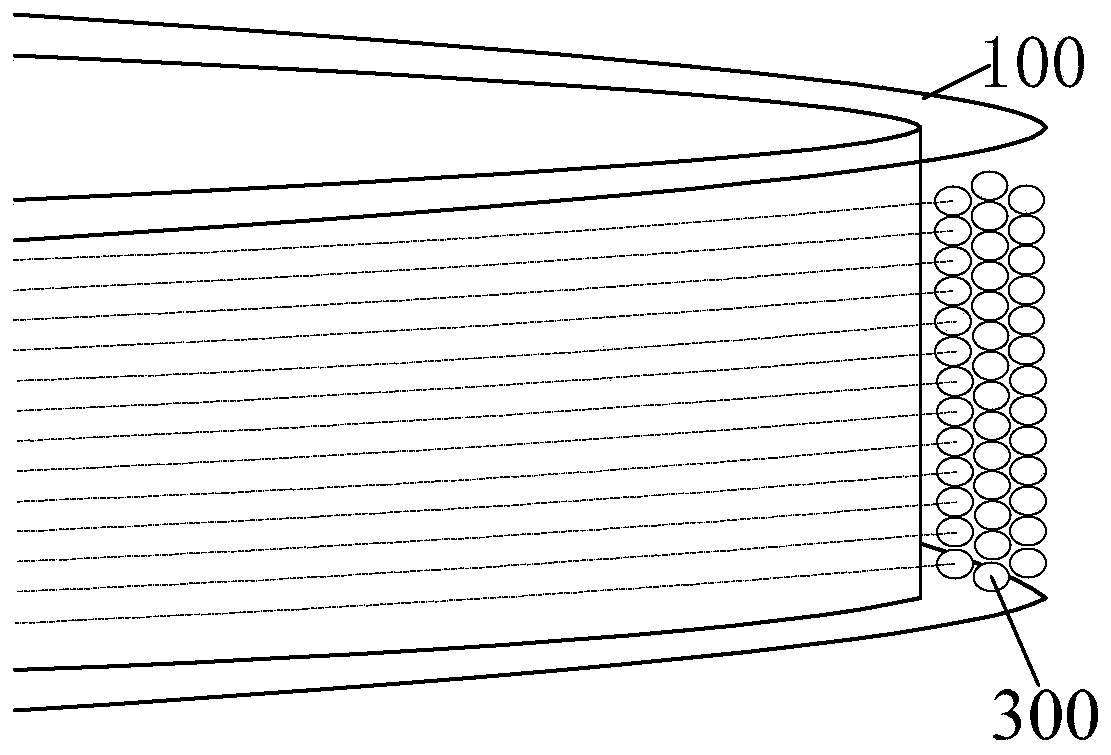

[0036] The metal detection device includes a receiving coil 200, a transmitting coil 300, a winding bobbin 100, a circuit board 20, a signal conditioning circuit 21 and a software module (not shown in the figure). The receiving coil 200 includes a main coil 201 and a secondary coil 202; and the transmitting coil 300, the secondary coil 202 and the primary coil 201 are arranged independently on the circuit board 20 according to a concentric structure from inside to outside, and the transmitting coil 300, the primary coil 201, the secondary coil The respective start ends and end ends of 202 are respectively electrically connected to corresponding components on the circuit board 20 .

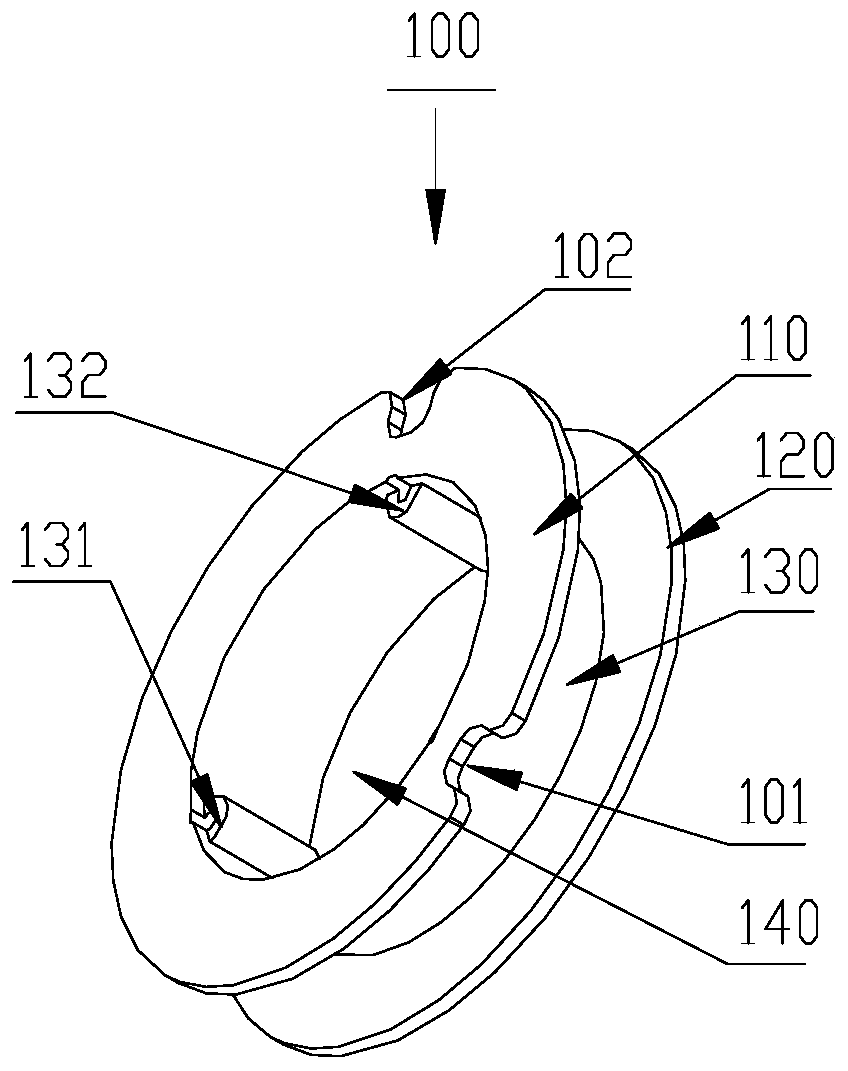

[0037] The winding frame 100 is made of non-conductive material, such as plastic material, ferrite PVC material, phenol bakelite, ceramic lamp and other materials, preferably the winding frame 100 is made of PVC material with certain flexibility and low cost. The winding frame 100 is a columnar str...

Embodiment 2

[0060] The main difference between the metal detection device in this embodiment and Embodiment 1 is as follows:

[0061] like Figure 5A As shown, the secondary coil 202 adopts a group of coils to form a ring-shaped structure (the solid line in the figure), and the area formed by the ring is an open ring, that is, a metal copper wire is used to press between adjacent coils. Staggered open loops are continuously wound to form multi-turn coils and printed on the circuit board 20 . The metal copper wire includes a starting point E and an ending point D. The main coil 201 also adopts a circular ring structure (the dotted line in the figure) formed by a group of coils spirally surrounding multiple groups of coils, and the circular ring structure is a closed loop, which includes a starting point F and an ending point G point.

Embodiment 3

[0063] The main difference between the metal detection device in this embodiment and Embodiment 1 is as follows:

[0064] like Figure 5B As shown, the secondary coil 202 is divided into two closed-loop groups (2021, 2022), and each closed-loop group has a start end and an end end. The area formed by the two closed-loop groups (2021, 2022) is an open loop. The two closed-loop groups (2021, 2022) share a starting point E, the closed-loop group 2021 has an ending point D1, and the closed-loop group 2022 has an ending point D2. The overall structure formed by the inside of the two closed-loop groups (2021, 2022) is a circular ring, and the outside structure is a square ring structure and is an open ring; like this, the inside of the secondary coil 202 can be connected with the circle placed on the central circle 210. The shape and structure of the ring-shaped transmitting coil 300 are matched, and the outside can be matched with the shape and structure of the square-ring struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com