A Fatigue Test System for Smart Pantograph Carbon Skateboard with Good Adaptability

A pantograph carbon skateboard, fatigue testing technology, applied in the testing of mechanical components, testing of machine/structural components, using stable tension/pressure to test the strength of materials, etc., can solve the problems of endangering driving safety and achieve operation Convenience, improved detection efficiency, accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

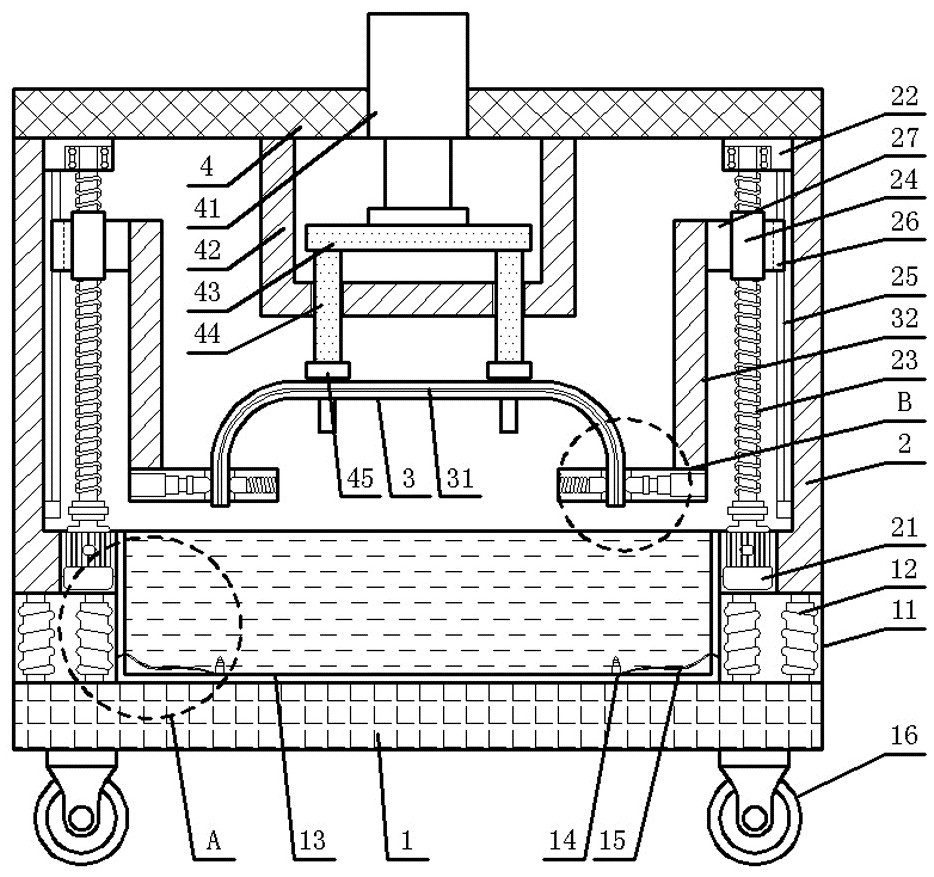

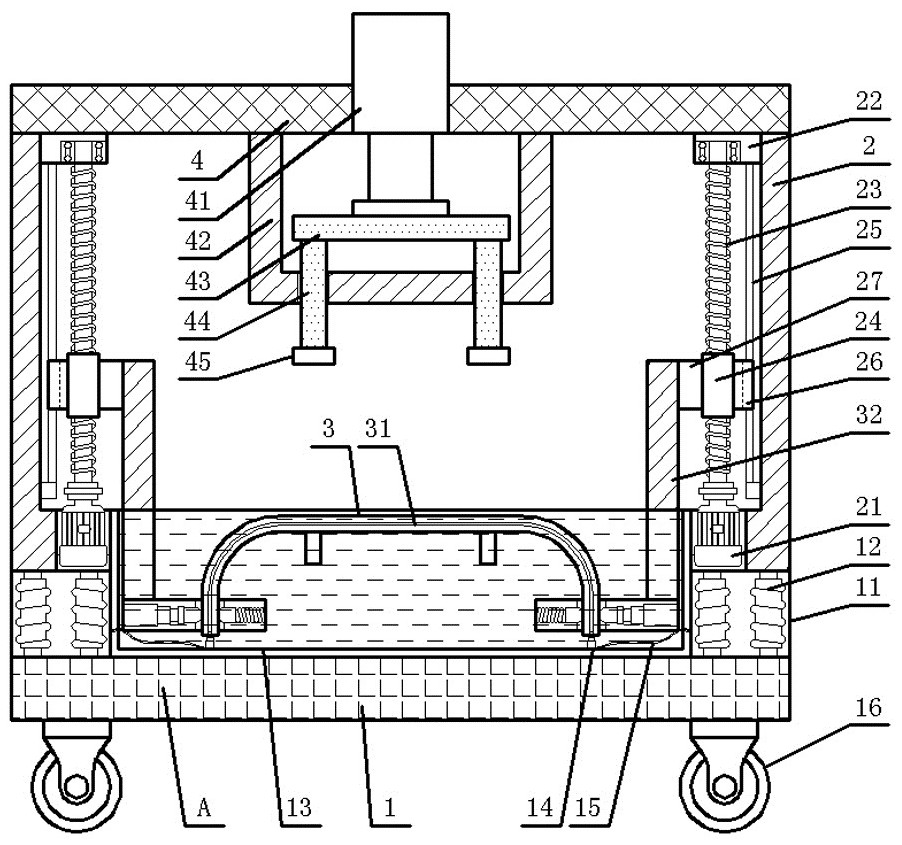

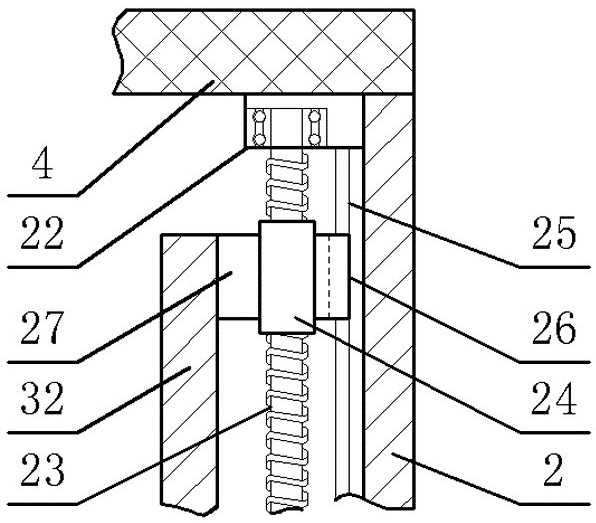

[0025] Example: see Figure 1-6 , an intelligent pantograph carbon skateboard fatigue testing system with good adaptability, comprising a bottom plate 1, the bottom plate 1 is a rectangular plate placed horizontally and horizontally, a water tank 13 is arranged on the top surface of the bottom plate 1, and the water tank 13 is a top A rectangular box with an open surface, the water tank 13 is provided with a carbon sliding plate 3 facing upward, the carbon sliding plate 3 is in the shape of a bow with the opening facing downward, and is located at the bottom of both sides of the water tank 13 and at both ends of the top surface of the bottom plate 1. A base 11 is provided, and the base 11 is a hollow square block; a vertically placed riser 2 is provided on the outside of the top surface of each base 11, and a driving mechanism is installed on the inner side of each riser 2 , the outer end surface of the connecting block 27 in the drive mechanism is fixedly connected to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com