Production equipment and process of bicycle folding seat

A technology of production equipment and folding seats, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of no production equipment, etc., and achieve the effect of improving production efficiency and large market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

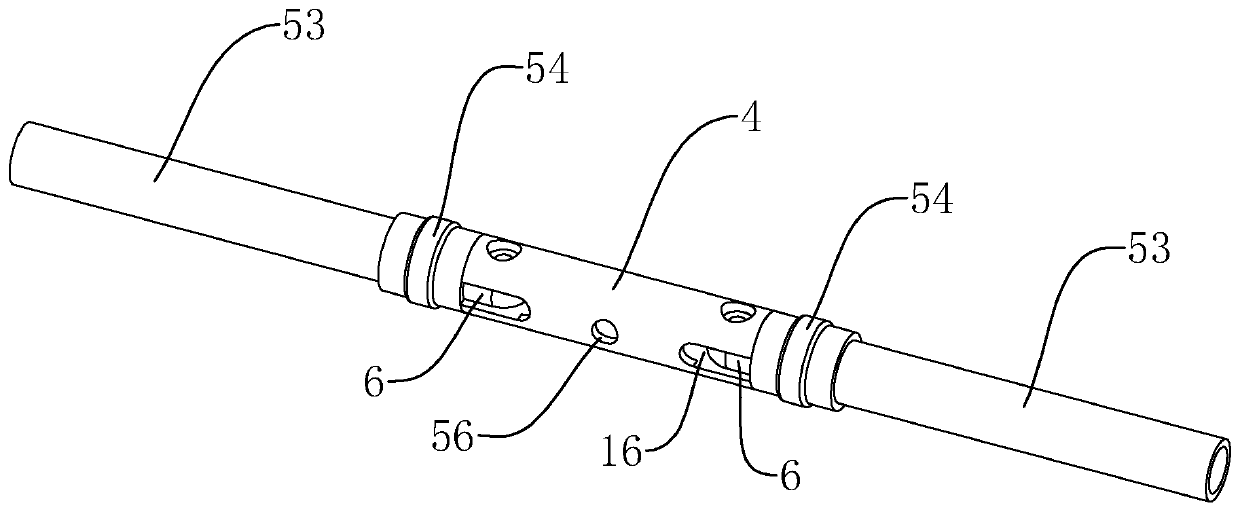

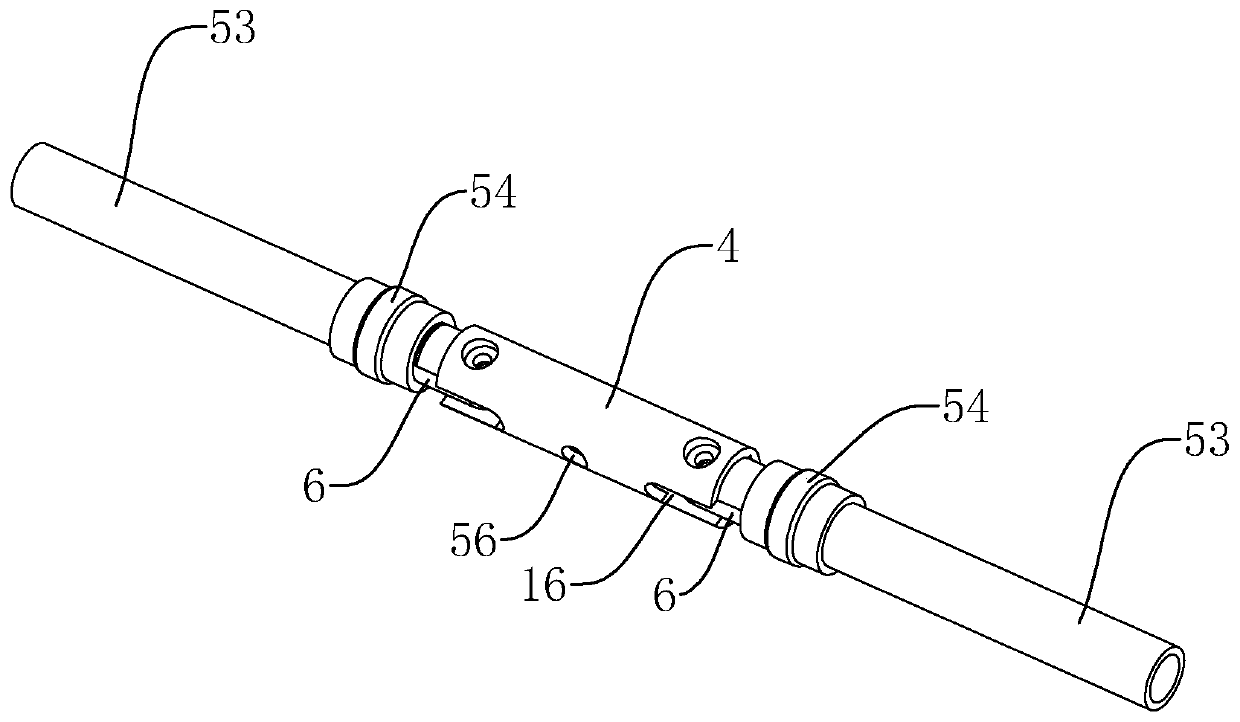

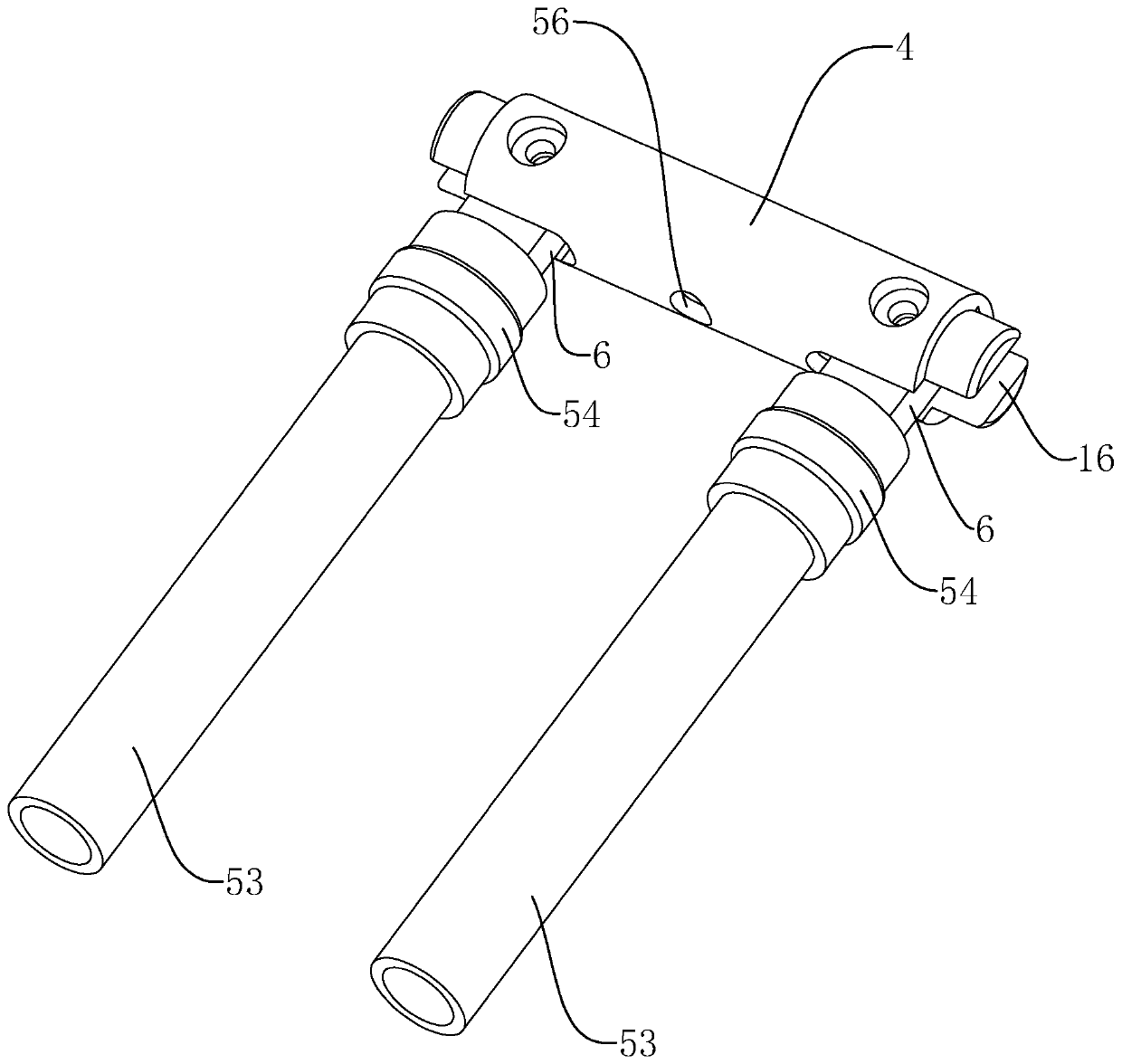

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0049] Such as Figure 5 As shown, a kind of production equipment of bicycle folding seat comprises conveyor belt 40, and the initial end of conveyor belt 40 is provided with the storage box 41 that is used to store front mounting bar 4 blanks and lock piece 6 blanks, and the tail end of conveyor belt 40 is respectively provided with The headstock is equipped with a rod discharge box 42 and a lock piece discharge box 43 .

[0050] One side of the conveyor belt 40 is provided with a first lathe 44 and a second lathe 45 which can sequentially process the headstock mounting rod 4 blanks along the direction from its initial end to the tail end, and the other side of the conveyor belt 40 is along its initial end to the tail end. Direction is provided with the 3rd lathe 46, the 4th lathe 47 and the 5th lathe 48 that can carry out sequential processing to lock piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com