A quick disassembly device for scrapped automobile wheels

A technology for scrapping cars and dismantling devices, which is applied in the directions of wheel assembly and disassembly equipment, wheel and tire installation, etc., can solve the problem of cumbersome disassembly process, and achieve the effect of avoiding manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

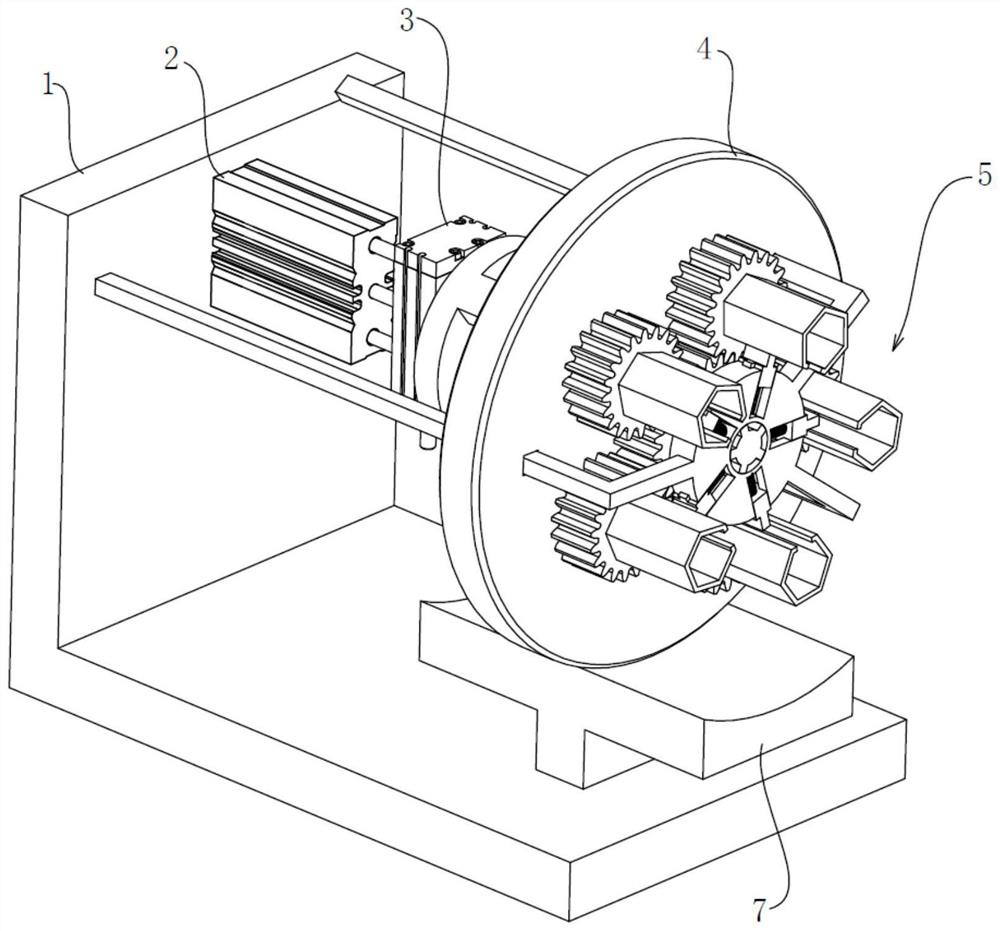

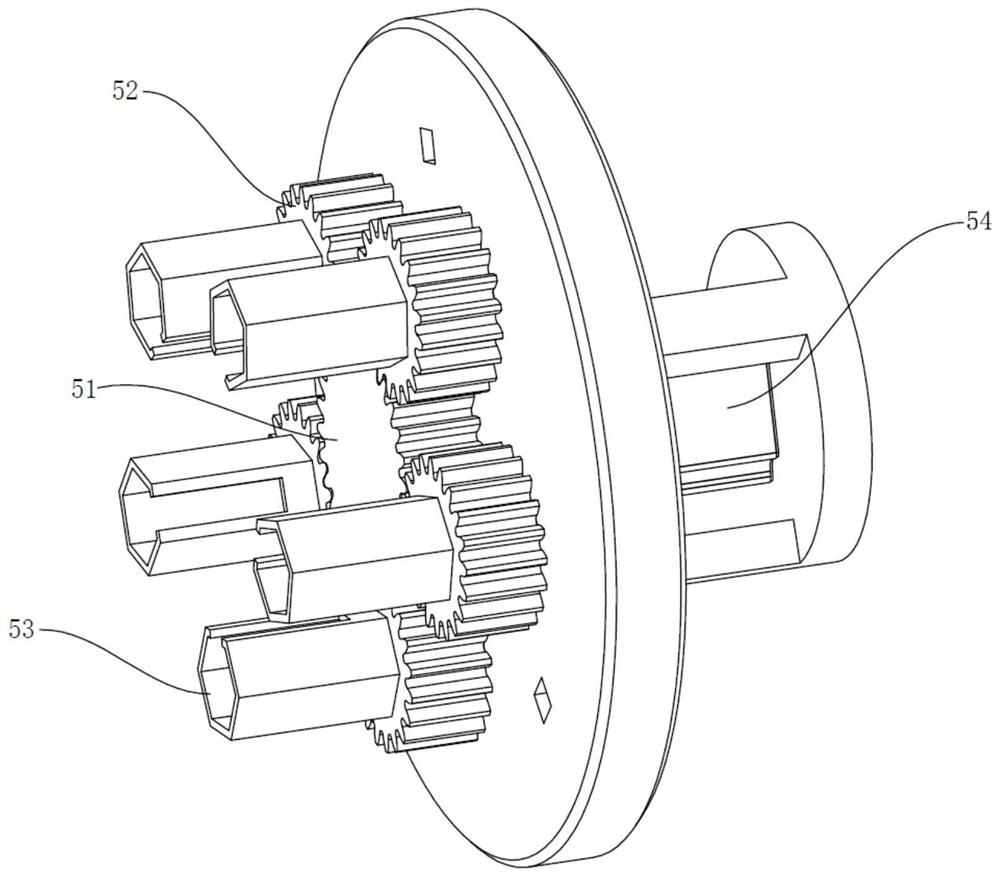

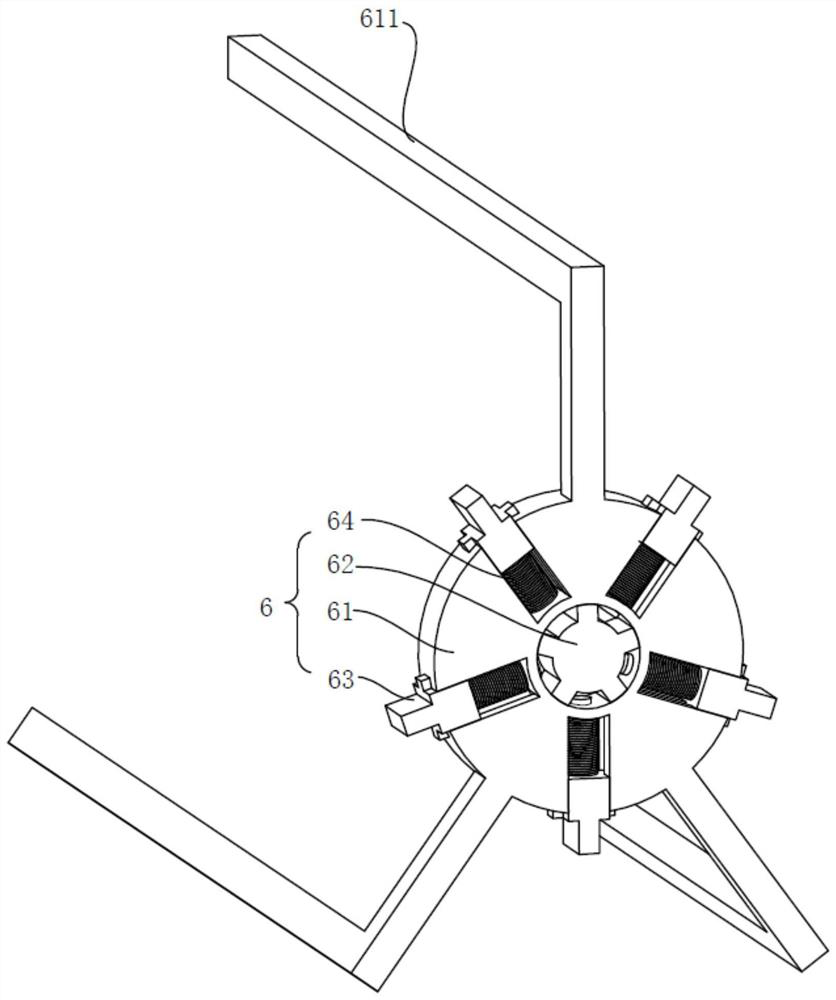

[0022] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0023] A wheel quick disassembly device for scrapped automobiles, comprising a bracket 1, a biaxial hydraulic cylinder 2, a rotary cylinder 3, a turntable 4, a bolt removal mechanism 5, an ejection mechanism 6 and a support frame 7, wherein:

[0024] The double-axis hydraulic cylinder 2 is fixedly installed on the side plate of the bracket 1 by bolts, the power output end of the double-axis hydraulic cylinder 2 is fixedly installed with the rotary cylinder 3 by bolts, and the turntable 4 is fixedly installed on the power output end of the rotary cylinder 3 by bolts , the support frame 7 is fixedly installed on the bracket 1 by bolts, and the support surface of the support frame 7 is in contact with the turntable 4, wherein the support surface of the support frame 7 is adapted to the outer circular surface of the turntable 4, thereby preventing the turntable 4 from being installed by a can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com