A preparation method of enteric-coated drug packaging material polyacrylic acid resin II

The technology of polyacrylic acid resin and methacrylic acid is applied in the field of preparation of enteric-coated pharmaceutical packaging material polyacrylic acid resin II, which can solve problems such as unfavorable continuous production, adding materials, and a large amount of foam in emulsion, and achieves low irritation, The effect of improving reactivity and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

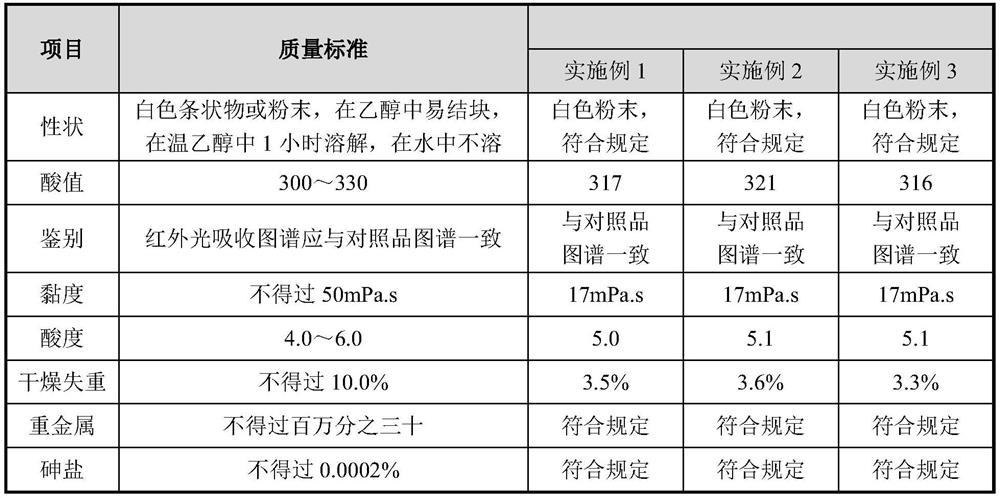

Examples

Embodiment 1

[0039] (1) raw material: methacrylic acid 120g; methyl methacrylate 120;

[0040] Initiator: ammonium persulfate 0.5g;

[0041] Emulsifier: sodium dodecyl sulfonate 1.5g; soybean lecithin 8g;

[0042] Catalyst: ethylene glycol titanium 1g;

[0043] Balance: deionized water 750g;

[0044] Add 750g deionized water, 0.5g ammonium persulfate, 1.5g sodium dodecyl sulfonate; 8g soybean lecithin into the reaction kettle, stir for 15 minutes, add 30g methacrylic acid and 30g methyl methacrylate, while stirring While adding 1g of ethylene glycol titanium, after all the catalysts were added, continue to stir for 20 minutes; mix the remaining 90g of methacrylic acid and 90g of methyl methacrylate, and then move it into a dropping funnel and add dropwise at a rate of 1.5ml / min into the reaction kettle, continue to react at room temperature for 1 hour after the dropwise addition, add methanol to break the emulsion, precipitate, filter with suction, and dry in vacuum to obtain polyacryli...

Embodiment 2

[0046] (1) raw material: methacrylic acid 150g; methyl methacrylate 150;

[0047] Initiator: potassium persulfate 1.0g;

[0048] Emulsifier: sodium dodecyl sulfonate 2.5g; soybean lecithin 5g;

[0049] Catalyst: ethylene glycol titanium 1.5g;

[0050] Balance: deionized water 690g;

[0051] 690g of deionized water, 1.0g of potassium persulfate, 2.5g of sodium dodecyl sulfonate; 5g of soybean lecithin were added to the reactor, stirred for 20 minutes, added with 50g of methacrylic acid and 50g of methyl methacrylate, and stirred while stirring While adding 1.5g of ethylene glycol titanium, after all the catalysts were added, continue to stir for 20 minutes; mix the remaining 100g of methacrylic acid and 100g of methyl methacrylate, and then move it into a dropping funnel, dropwise at a rate of 1.5ml / min Add it to the reaction kettle, continue to react at room temperature for 1 hour after the dropwise addition is completed, add methanol to break the emulsion, precipitate, fil...

Embodiment 3

[0053] (1) raw material: methacrylic acid 135g; methyl methacrylate 135;

[0054] Initiator: sodium persulfate 0.8g;

[0055] Emulsifier: sodium dodecyl sulfonate 2g; soybean lecithin 6g;

[0056] Catalyst: ethylene glycol titanium 2.5g;

[0057] Balance: deionized water 720g;

[0058] 720g of deionized water, 0.8g of sodium persulfate, 2g of sodium dodecyl sulfonate; 6g of soybean lecithin were added to the reactor, stirred for 20 minutes, added with 45g of methacrylic acid and 45g of methyl methacrylate, while stirring Add 2.5g of ethylene glycol titanium, and continue stirring for 20 minutes after all the catalysts are added; mix the remaining 90g of methacrylic acid and 90g of methyl methacrylate, and then move it into a dropping funnel, dropwise at a rate of 1.2ml / min into the reaction kettle, continue to react at room temperature for 1 hour after the dropwise addition, add methanol to break the emulsion, precipitate, filter with suction, and dry in vacuum to obtain po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com