Building body pile hole automatic blocking module

A sliding module and building technology, applied in construction, building maintenance, building construction, etc., can solve the problems of large workload of pile hole plugging and reduce the efficiency of pile hole plugging, so as to improve the plugging efficiency, Avoid troublesome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

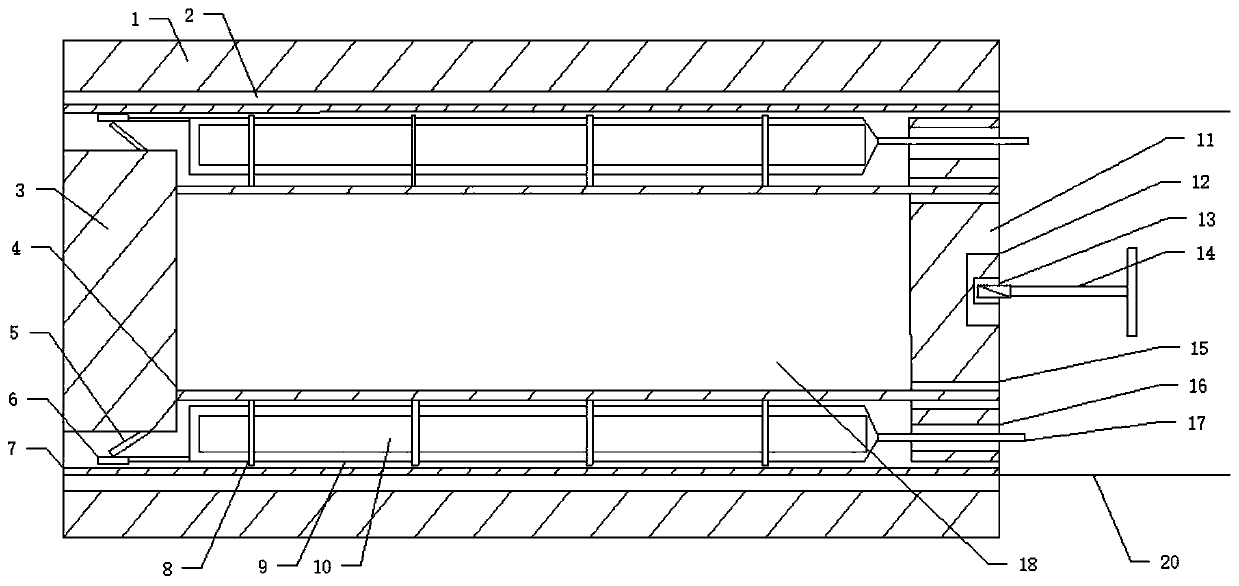

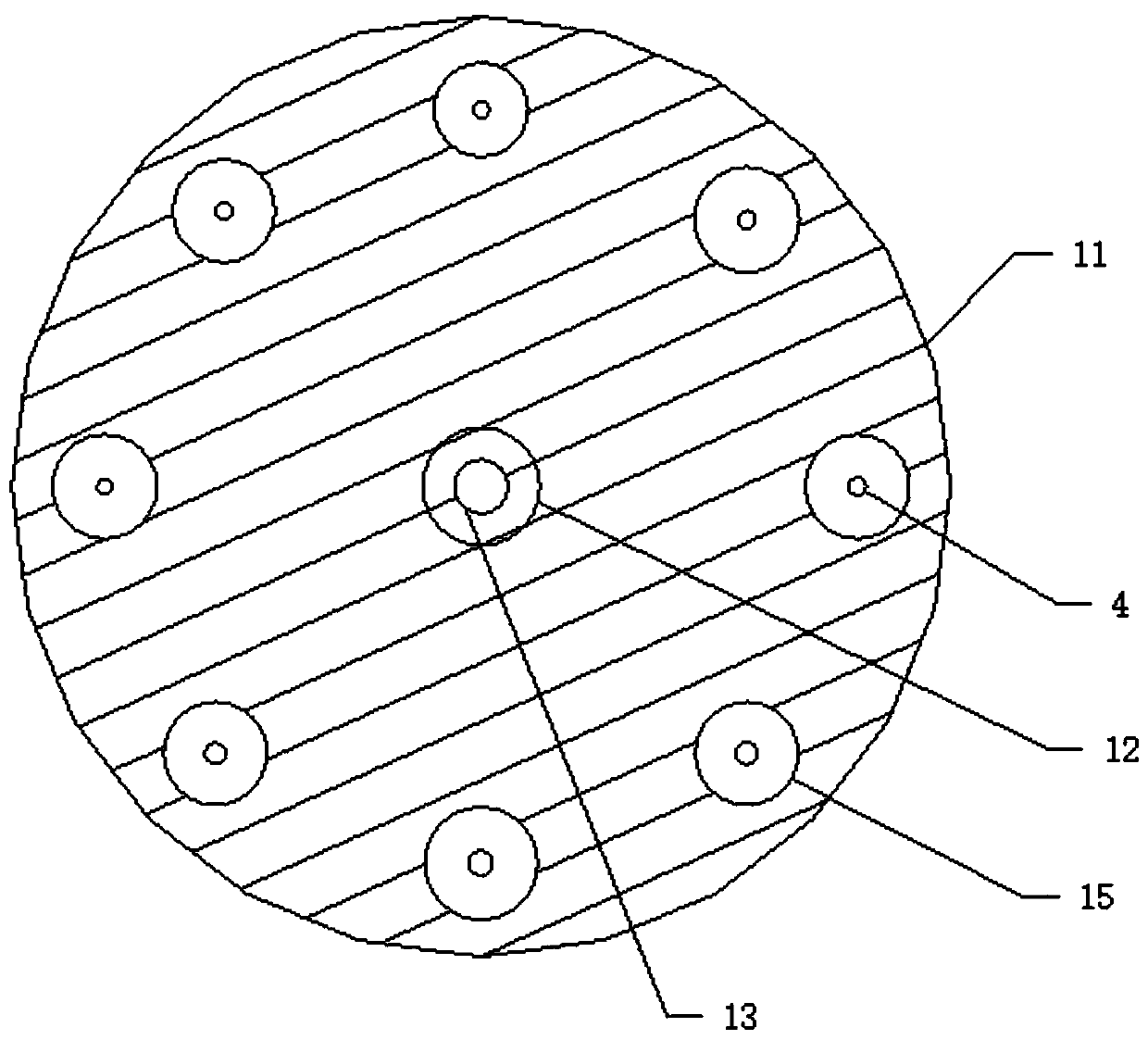

[0022] like Figure 1 to Figure 4 As shown, a building body pile hole automatic sealing module includes a wall 1, the wall 1 is provided with a pipe pile hole 2, and includes a cement fixing module 3 corresponding to the pipe pile hole 2 and The cement sliding module 11, the cement fixing module 3 is provided with a circle of supporting steel bars 4, the cement sliding module 11 is provided with the first sliding holes 15 corresponding to the supporting steel bars 4, and the supporting steel bars 4 are respectively provided with There is a water bag pipe 9, and a water cavity 10 is respectively arranged in the water bag pipe 9, and the first pull rope 17 for pulling the water bag pipe 9 to break is respectively arranged on the cement sliding module 11, and the cement fixing module 3 and the cement sliding module 11 are sleeved with a casing 7, and a cement cavity 18 is formed between the cement fixed module 3, the cement sliding module 11 and the casing 7, and dry cement is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com