A Controller Current Sampling System

A current sampling and controller technology, which is applied in the control system, current-only measurement, motor control, etc., can solve the problems of motor controller torque fluctuation, inability to work, controller fault signal, etc., to ensure normal operation and fast positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

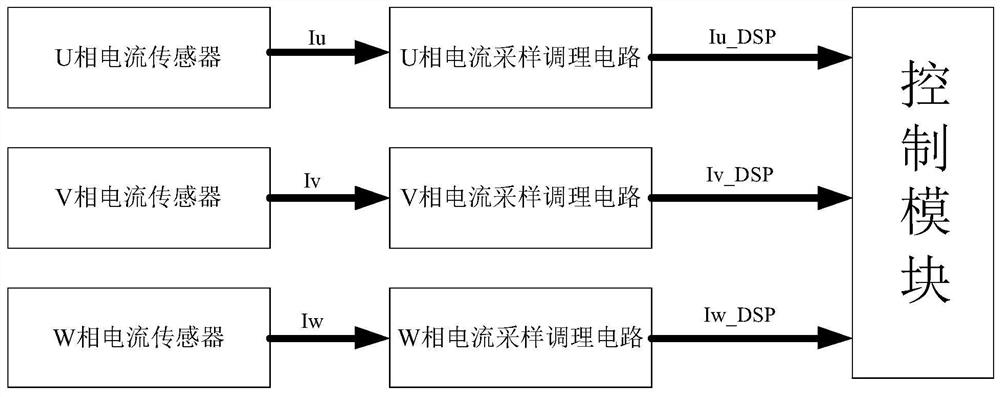

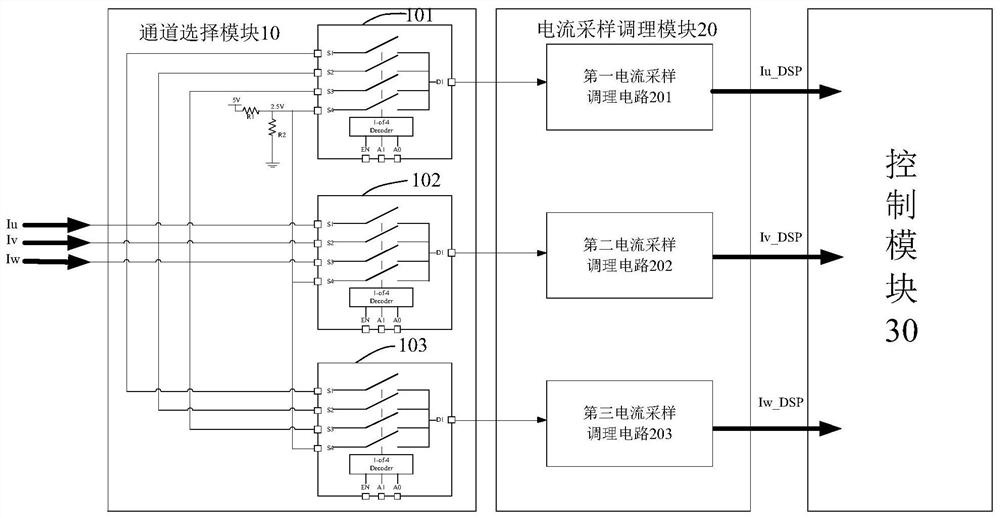

[0021] Embodiment: In practical application, the U-phase current signal Iu collected by the U-phase current sensor, the V-phase current signal Iv collected by the V-phase current sensor, and the W-phase current signal Iw collected by the W-phase current sensor. This application provides a controller current sampling system, such as figure 2 As shown, the system may include: a channel selection module 10 , a current sampling and conditioning module 20 , and a control module 30 .

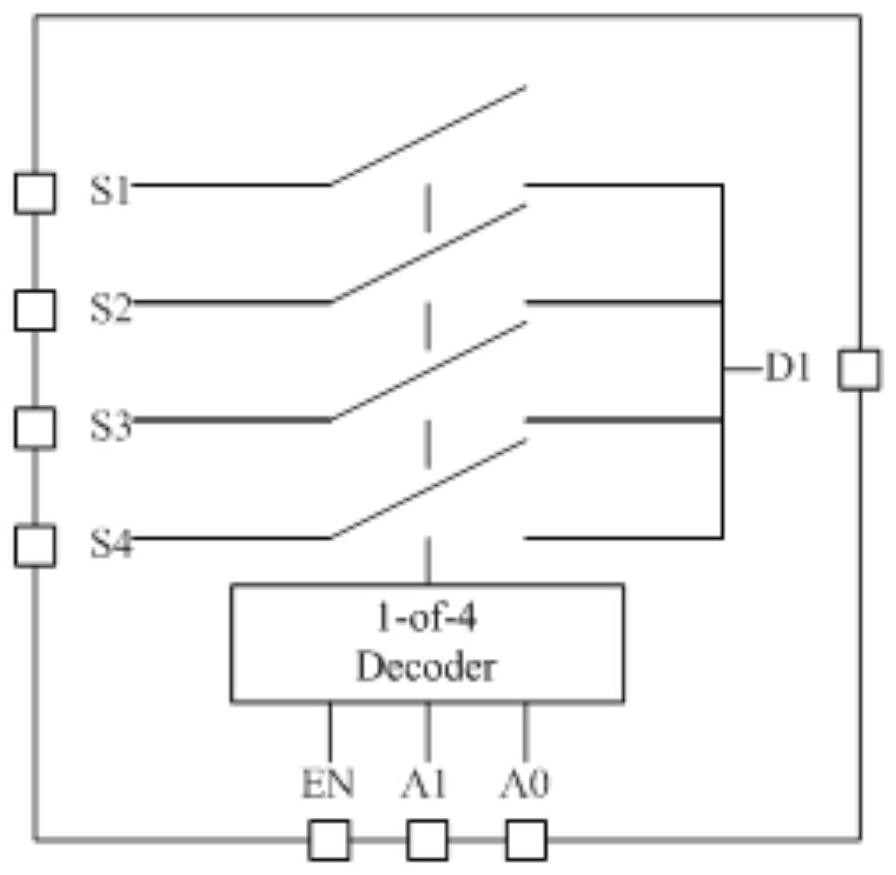

[0022] The channel selection module 10 includes a first channel selection submodule 101, a second channel selection submodule 102, and a third channel selection submodule 103; the current sampling and conditioning module 20 includes a first current sampling and conditioning circuit 201 and a second current sampling and conditioning circuit 202 , The third current sampling conditioning circuit 203.

[0023] The input of the first channel selection submodule 101, the second channel selection submodule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com