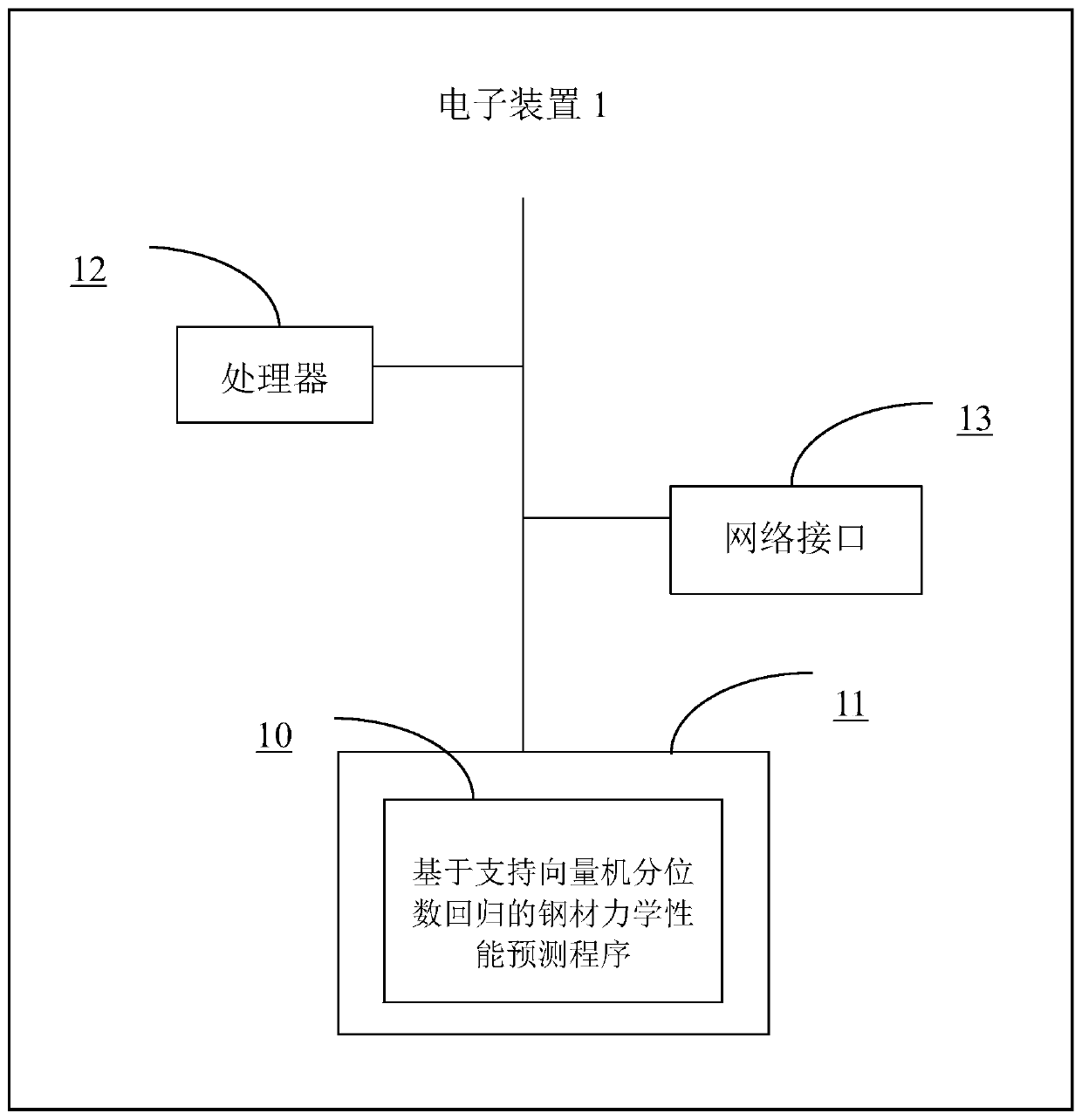

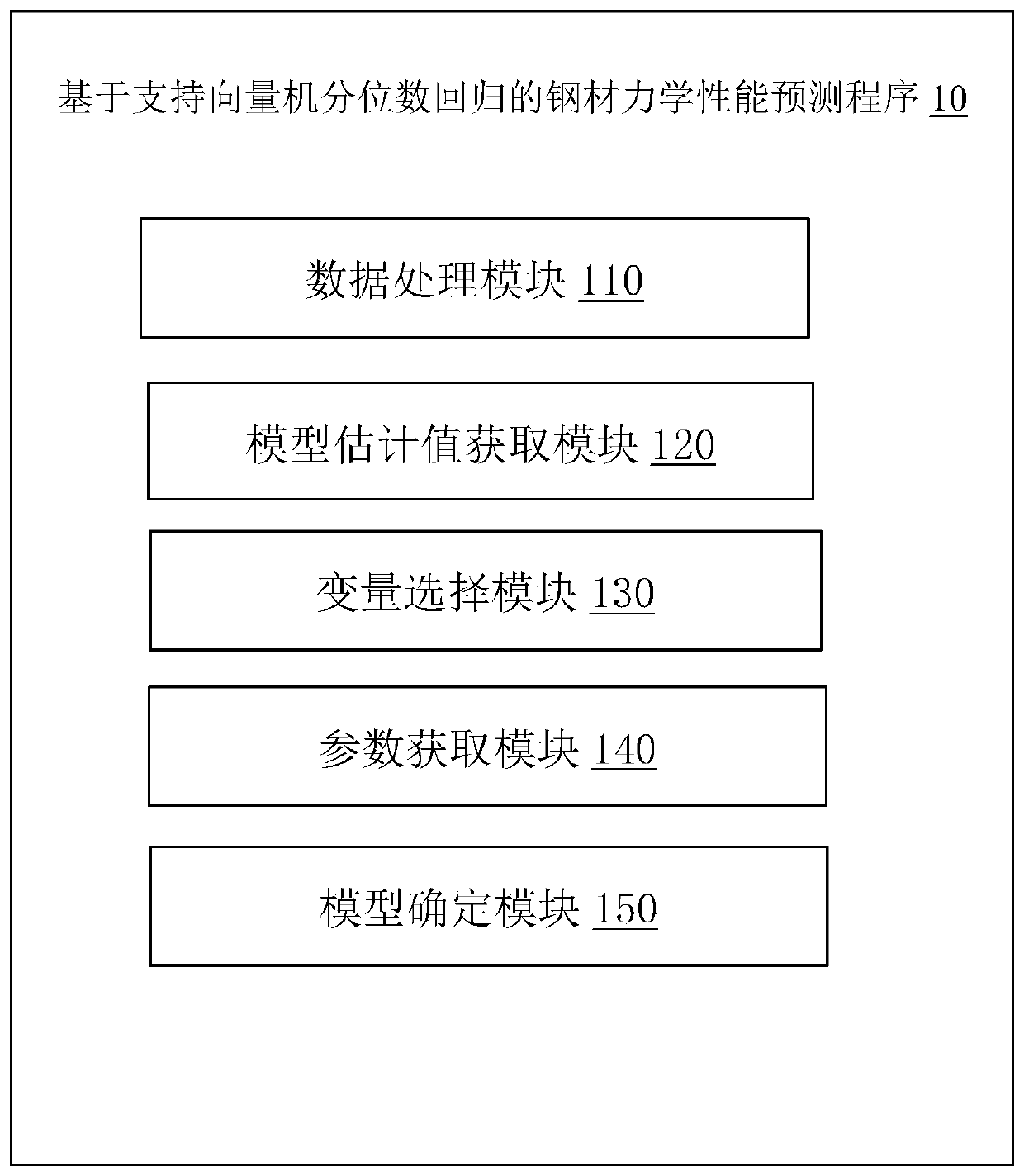

Steel mechanical performance prediction method based on support vector machine quantile regression

A technique of quantile regression and support vector machine, which is applied in specific mathematical models, computer materials science, kernel methods, etc., and can solve problems such as factor nonlinearity that cannot simultaneously consider data heterogeneity modeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

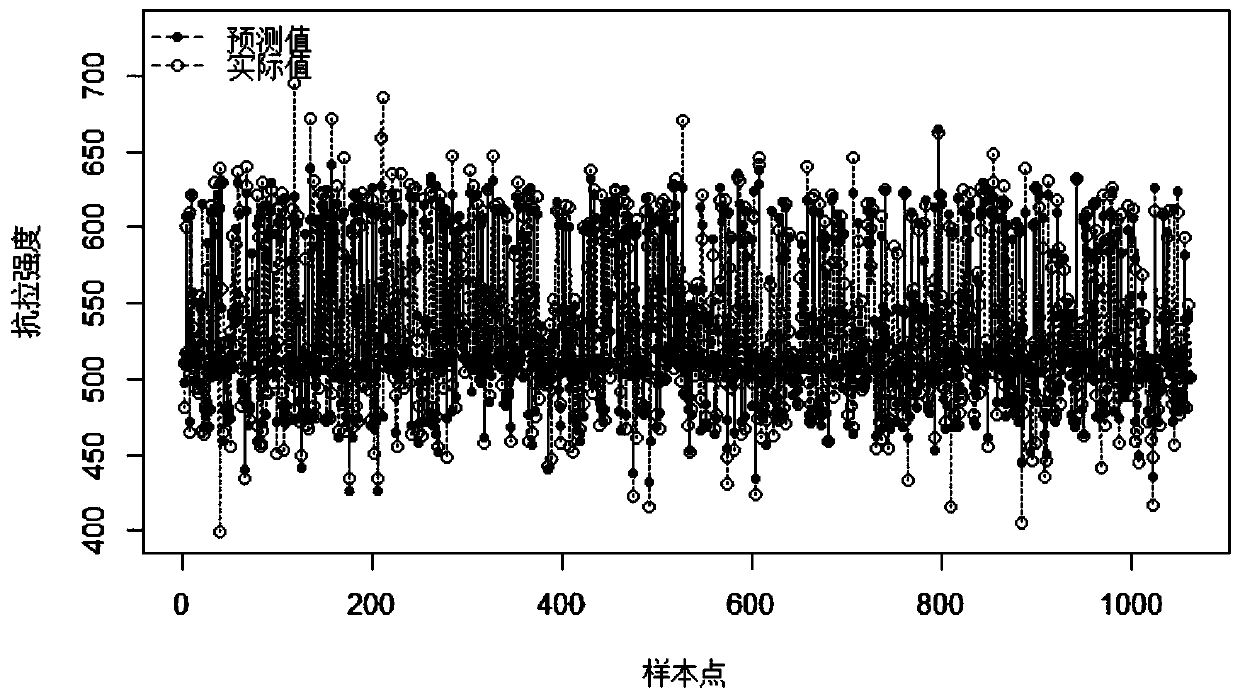

[0353] Based on the LASSO variable selection support vector machine quantile regression to predict the mechanical properties of steel, the specific implementation steps are as follows:

[0354] 1. Use formula (1) to standardize the original collected hot rolling data, and part of the standardized data is shown in Table 1

[0355] Table 1. Some data structures

[0356]

[0357]

[0358] 2. Select the appropriate kernel function

[0359] Divide standardized data into training set and test set, based on (25) formula, adopt described training set data to carry out backtesting to the training model that has been substituted into different kernel functions, select the kernel function with the best fitting effect according to the result of backtesting, As a suitable kernel function, the final prediction model is obtained. The kernel function selected in this embodiment is a Gaussian kernel function.

[0360]

[0361] 3. Determine the impact factor and adjust parameters an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com