Flywheel energy storage device, magnetic bearing and eddy current sensor assembly of magnetic bearing

An eddy current sensor and component technology, applied in the field of magnetic bearings, can solve the problems of insufficient measurement accuracy and large space occupation, and achieve the effects of convenient fixing and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

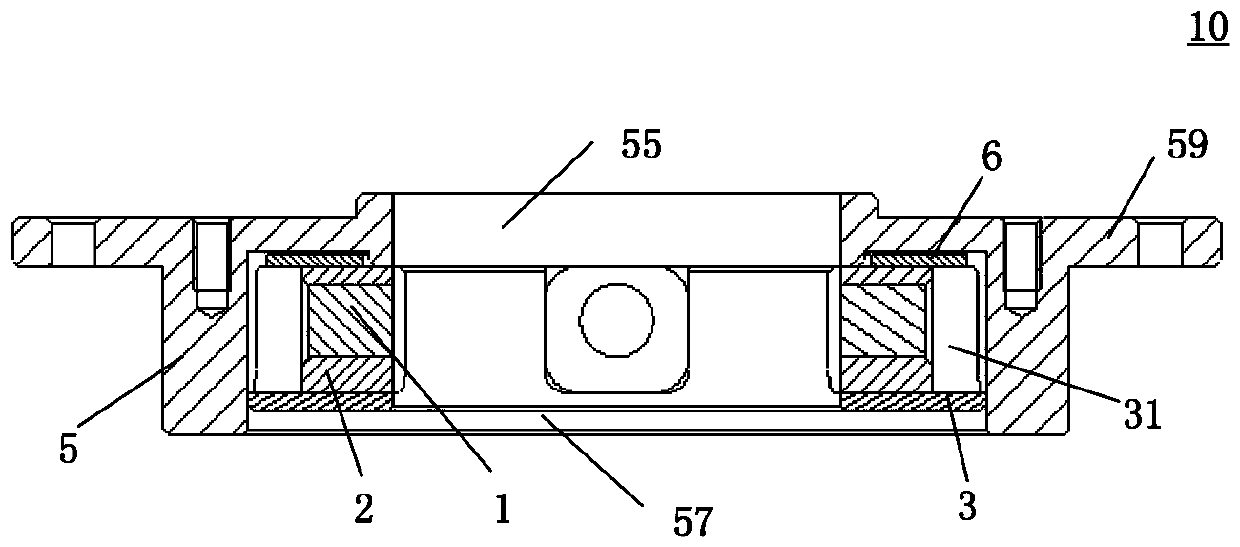

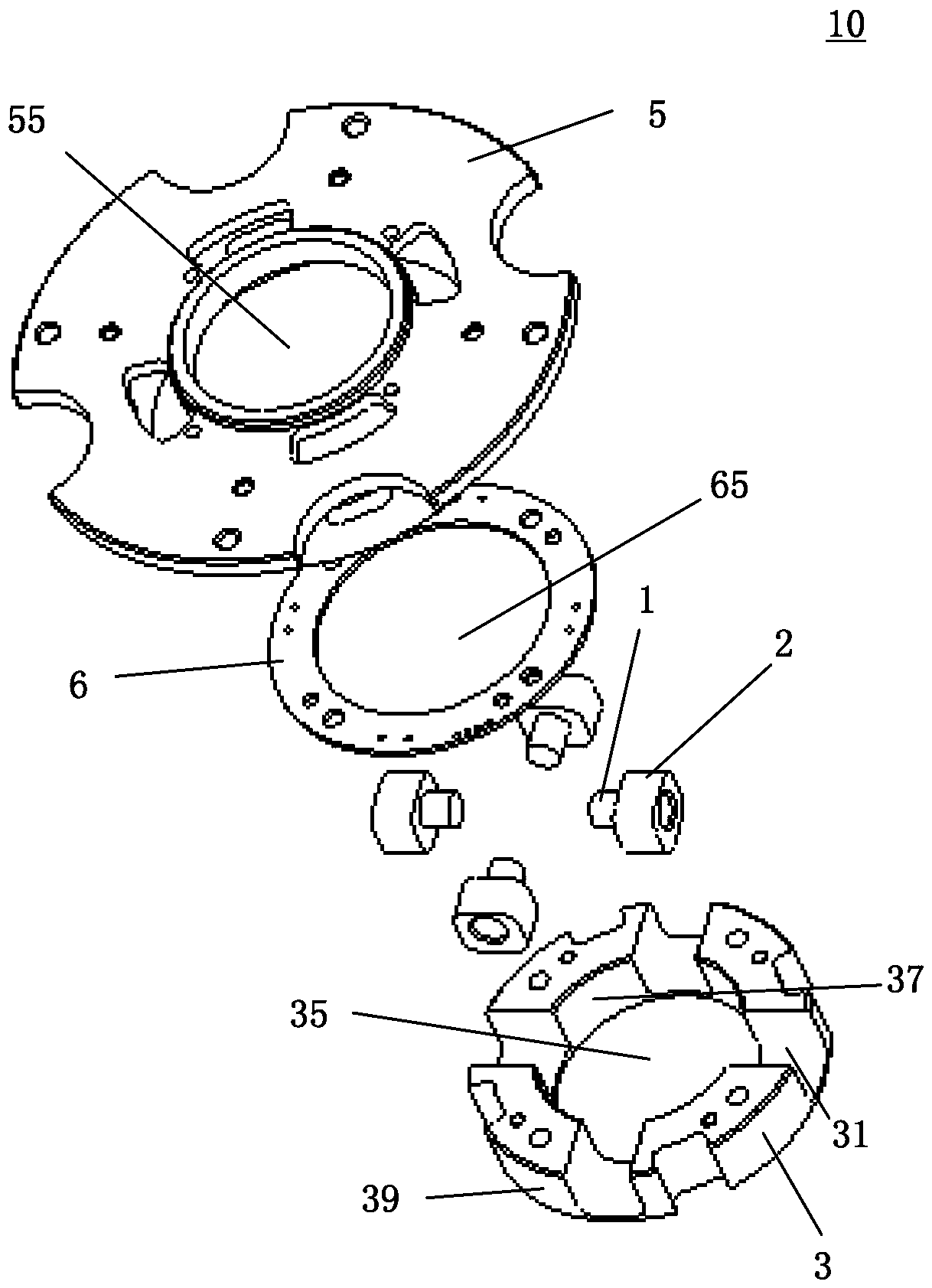

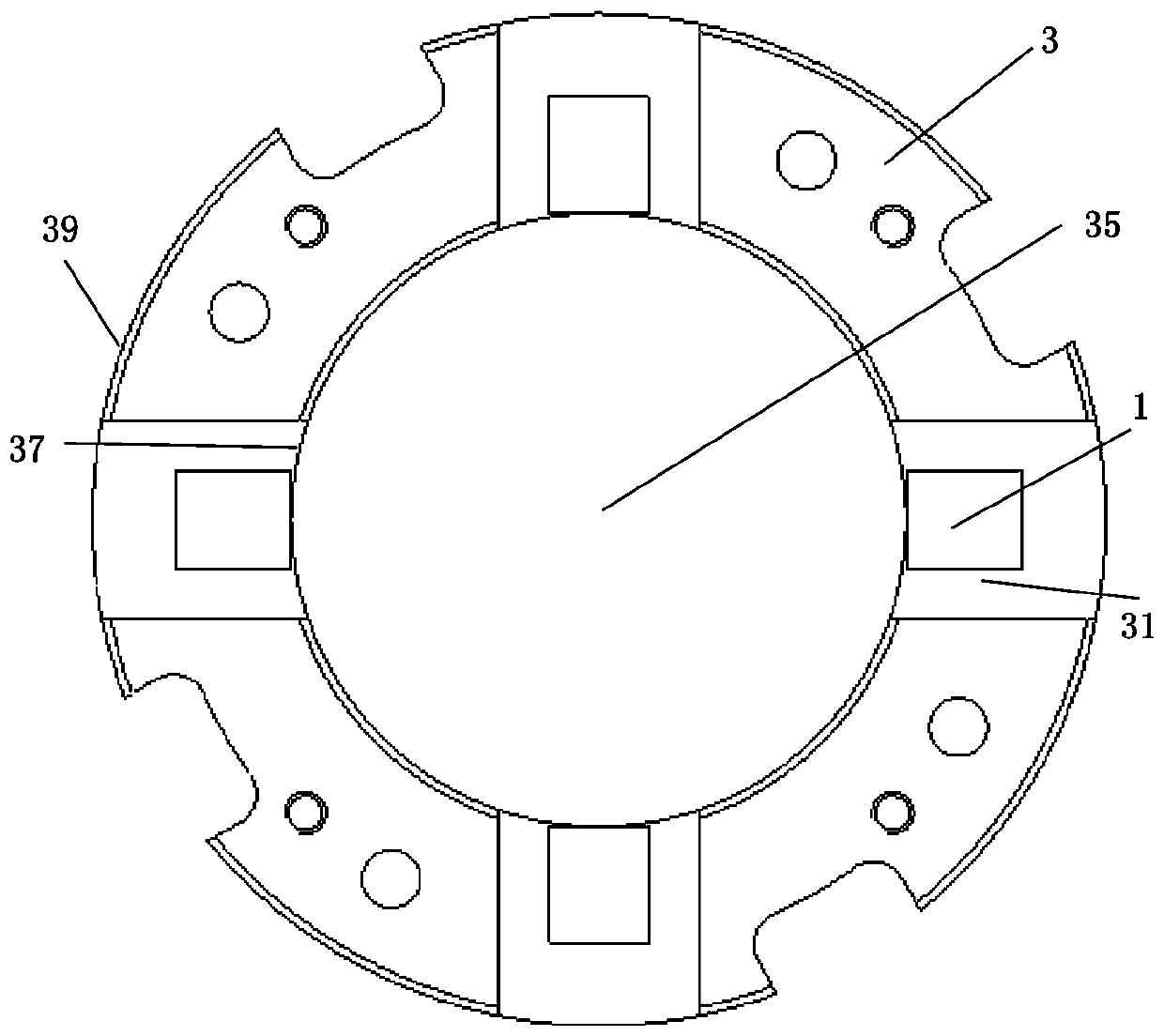

[0020] figure 1 It is a schematic diagram of the cross-sectional structure of the eddy current sensor assembly of the present invention. figure 2 It is an exploded perspective view of the eddy current sensor assembly of the present invention. image 3 It is a schematic diagram of the cooperation structure between the eddy current sensor and the first fixing base of the present invention. The present invention proposes an eddy current sensor assembly 10 , which roughly includes: four eddy current sensors 1 ; four protective covers 2 ; a first fixing seat 3 ; a second fixing seat 5 ; and a circuit board 6 .

[0021] Each eddy current sensor 1 is installed on a protective cover 2; each protective cover 2 equipped with an eddy current sensor assembly 1 is installed on the first fixed seat 3; the first fixed seat 3 and the second fixed seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com