Lampblack buffering mechanism for range hood

The technology of a range hood and a buffer mechanism is applied in the direction of removing oil fume, applications, and household stoves, etc. It can solve the problems of high oil fume resistance in public flues, affecting the discharge of oil fume, and obstruction of fume exhaust, so as to reduce the pressure of back-filling oil fume and slow down the discharge of oil fume. Smoke resistance, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

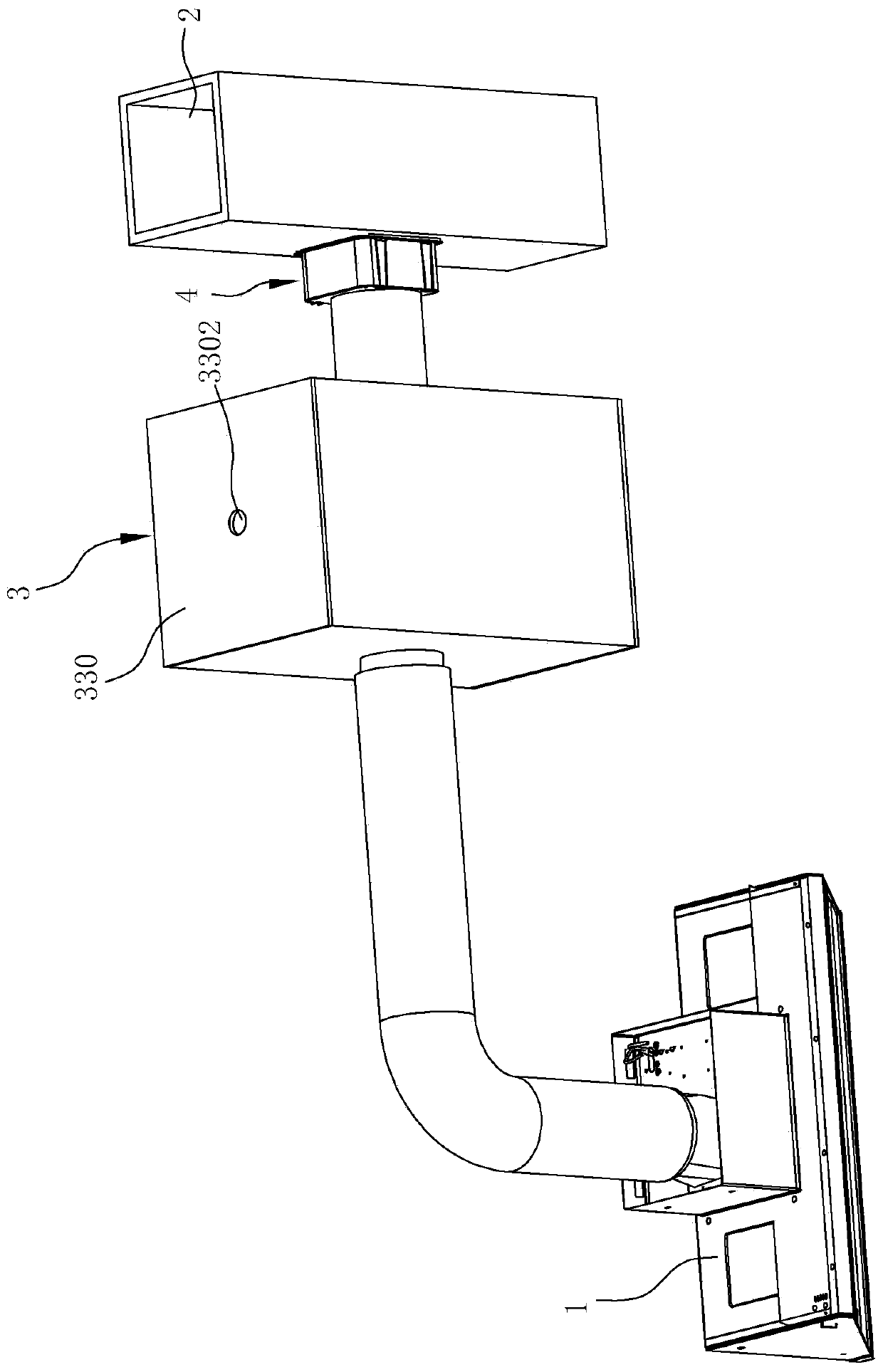

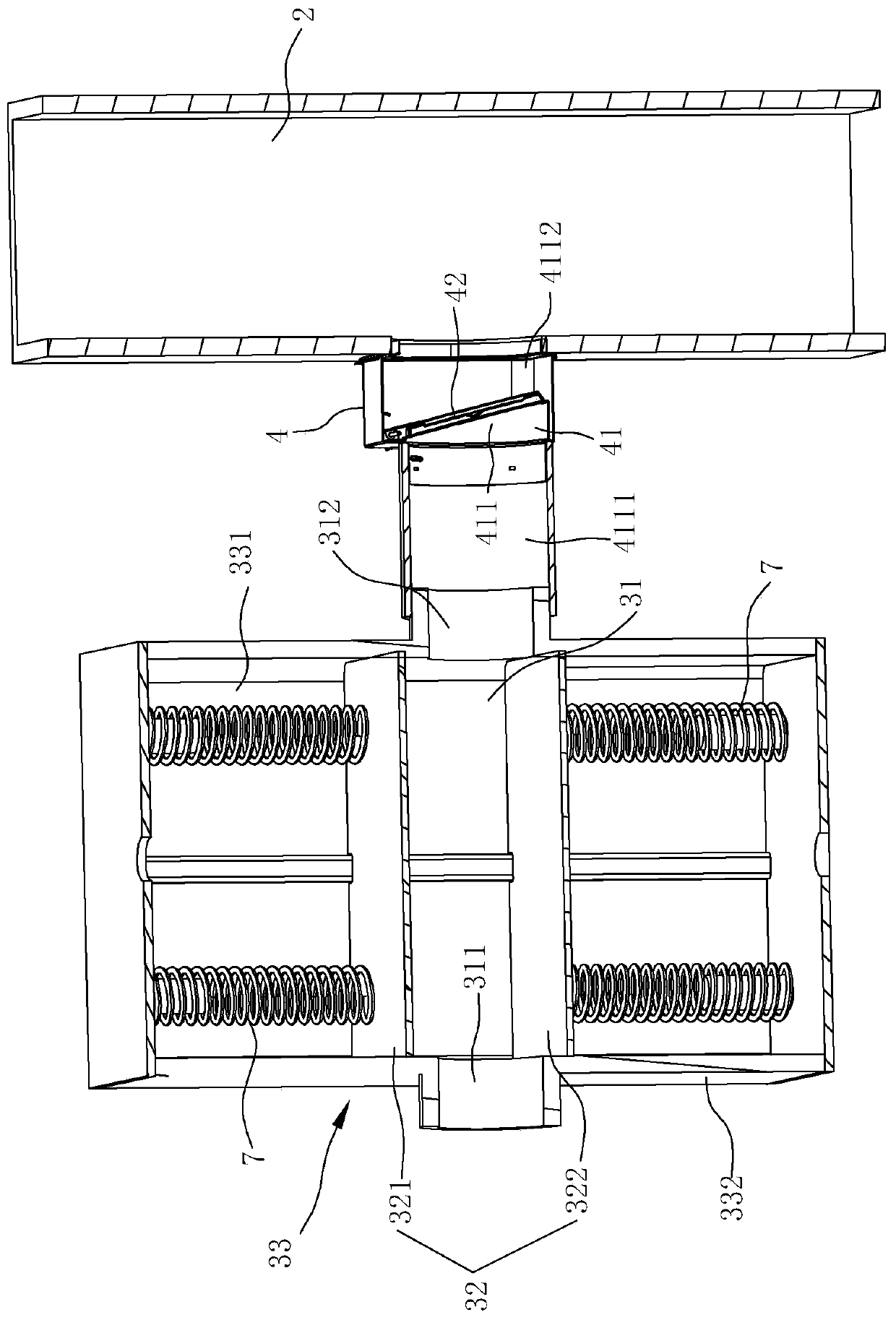

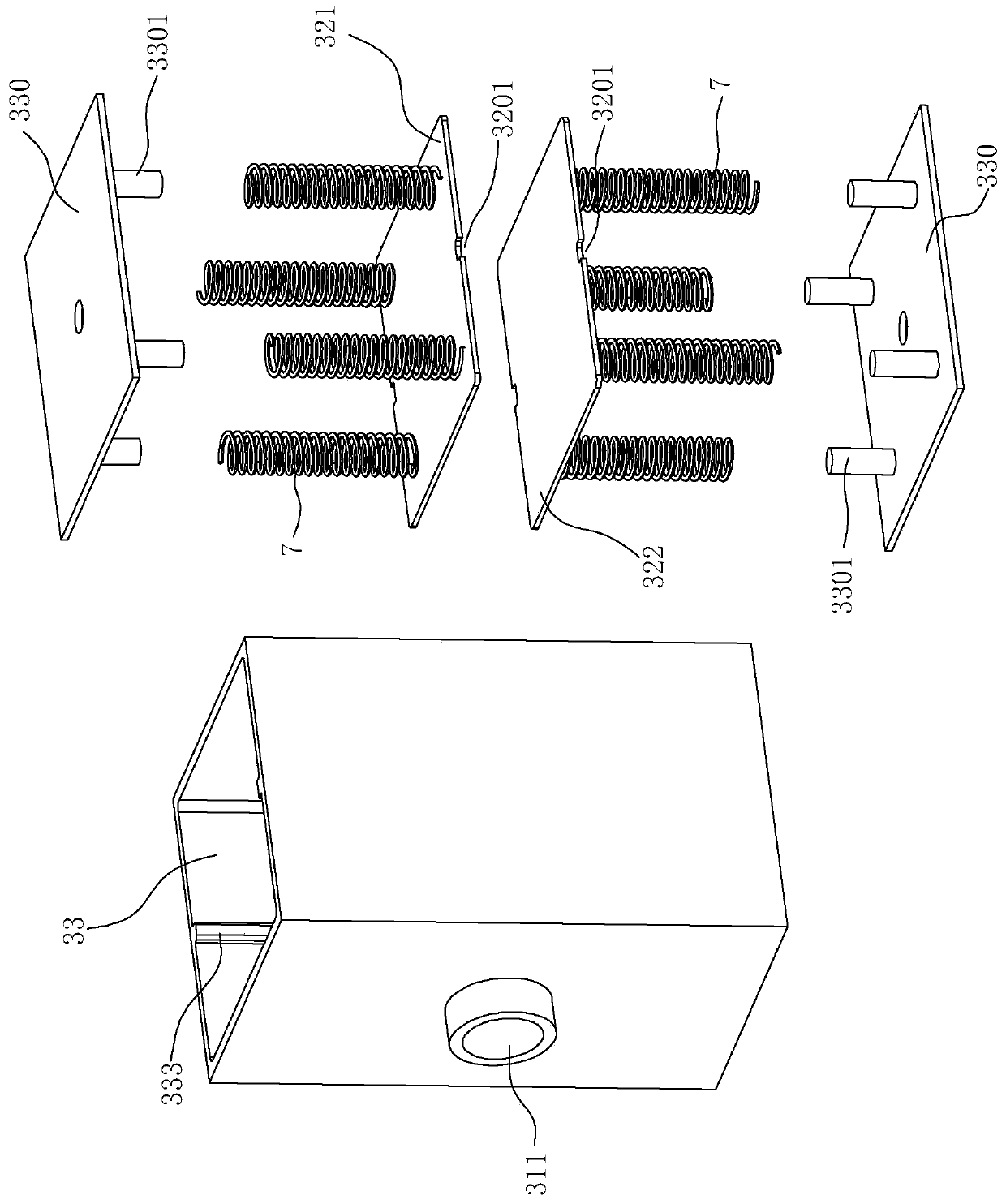

[0051] Such as Figure 1 to Figure 3 Shown is the first preferred embodiment of the invention. The fume buffering mechanism for the range hood of this embodiment includes a check valve 4 and a fume buffering device 3 .

[0052] The check valve 4 of this embodiment includes a valve body 41 and a valve plate 42, wherein the valve body 41 is provided with a connecting frame 43 and a rotating shaft 44 capable of rotating around its own axis, and the first end of the connecting frame 43 is opposite to the rotating shaft 44 fixed, the second end of the connecting frame 43 is relatively fixed with the valve plate 42, that is, the valve plate 42, the connecting frame 43 and the rotating shaft 44 rotate synchronously, and the valve body 41 has a smoke exhaust passage 411, and the smoke exhaust passage 411 has a The air outlet of the hood 1 is in fluid communication with the air inlet 4111 and the air outlet 4112 for fluid communication with the public flue 2. The valve plate 42 is arr...

Embodiment 2

[0059] Such as Figure 4 and Figure 5 Shown is the second embodiment of the present invention. The difference between this embodiment and the above-mentioned first embodiment is that the buffer device 3a is different. The buffer device 3a is provided with a first driving mechanism for driving the first movable plate 321a and the second movable plate 322a to slide in and out along the lateral direction.

[0060] The above-mentioned first drive mechanism includes a motor 61a and a first transmission member, the power output end of the motor is connected with the first transmission member, and the power output end of the first transmission member acts on the first movable plate 321a and the second movable plate 322a . The first transmission member in this embodiment includes a first rack 63a and a second rack 64a, the auxiliary cavity 33a includes a first auxiliary cavity 331a and a second auxiliary cavity 332a, and the inner peripheral wall of the first auxiliary cavity 331a ...

Embodiment 3

[0066] Such as Figure 6 to Figure 8 Shown is the third embodiment of the present invention. The difference between this embodiment and the above-mentioned second embodiment is that the transmission parts of the driving mechanism are different. Specifically, the driving mechanism includes a motor 61b and a first transmission part, and the power output end of the motor 61b is connected to the power output of the first transmission part. The ends are connected, and the power output end of the first transmission member acts on the first movable plate 321b and the second movable plate 322b. The first transmission part is a screw rod 62b, which extends along the transverse direction of the main oil fume passage 31b, and the screw rod 62b has a first threaded segment 621b and a second threaded segment 622b, and the helical direction of the thread on the first threaded segment 621b is the same as that of the second threaded segment. The threads on the two threaded sections 622b have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com