Sanitary pit toilet equipment for conveying and transferring excrement in mechanical auger mode

A technology of flooding and excrement, applied in sanitation equipment, resistance to vector-borne diseases, household appliances, etc., can solve problems such as heavy odor and insufficient sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

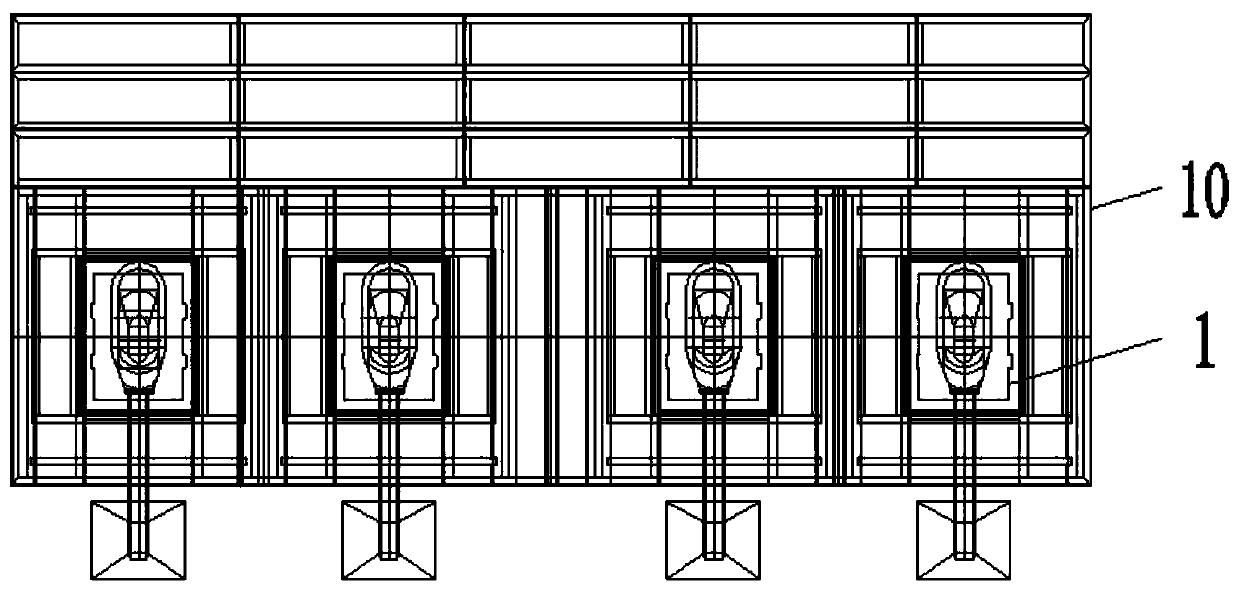

[0024] A kind of hygienic dry toilet equipment for transporting and transferring feces by mechanical dragon type, which includes a squatting pan 1 and a dragon-driven transmission mechanism. The transport mechanism is also provided with a straw powder funnel 3, which is filled with sawdust and straw powder that can absorb moisture and cover the manure. Jiaolong drives the transport mechanism to transport the sawdust and straw powder to the trapezoidal funnel 2 and the manure. Mix and drain. The squatting pan 1 adopts an integral frame to fix the squatting pan 1 with an open and closed door panel for blocking odor.

[0025] Among them, the Jiaolong drive transmission mechanism uses a screw conveyor to transport the sawdust and straw powder to the trapezoidal funnel 2, mixes with the feces, and then discharges it to the rear of the toilet house to store the septic tank or septic tank. A screw conveyor is equipped with a straw powder box. Cover the manure when toileting, and at ...

Embodiment 2

[0029] The difference technology of embodiment two compared with embodiment one is as follows:

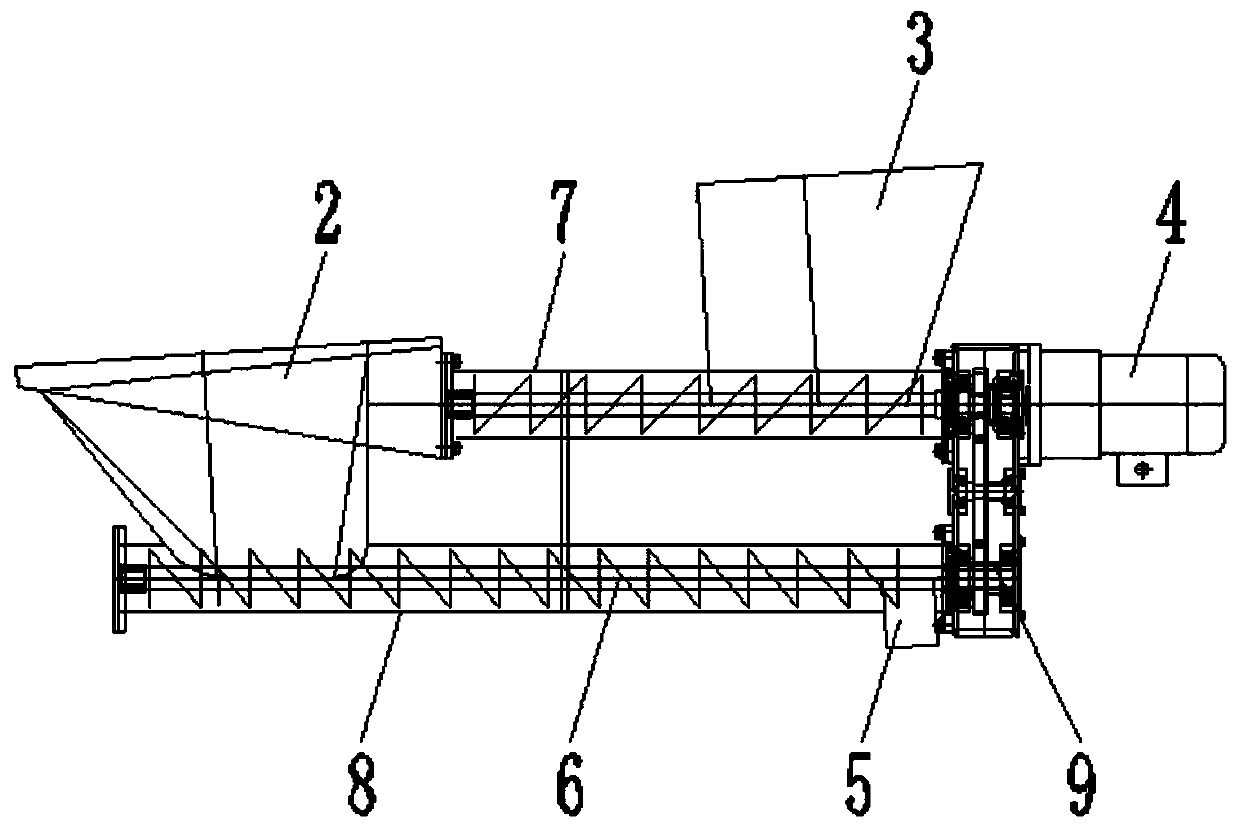

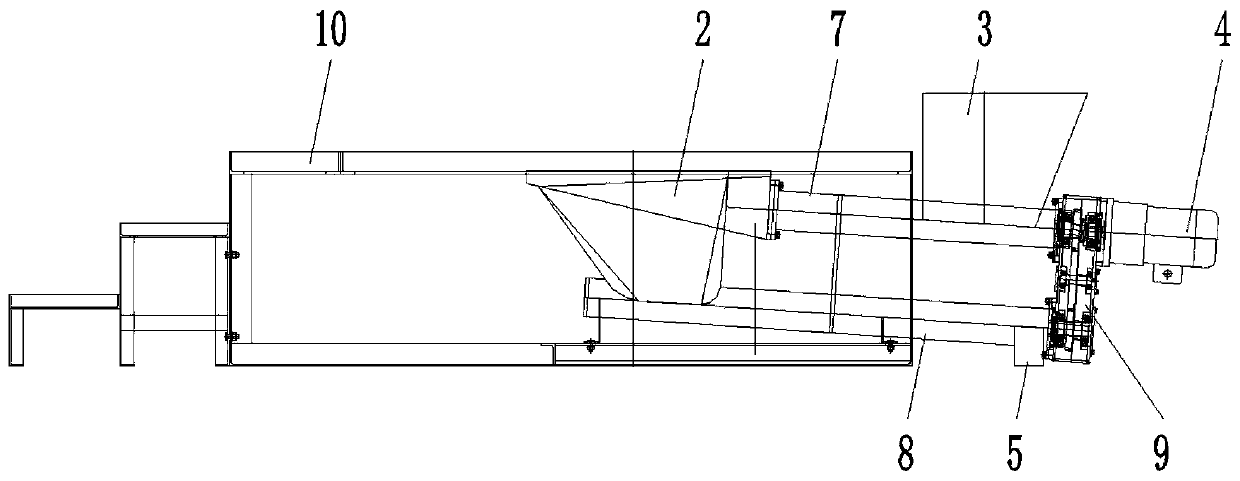

[0030] In the second embodiment, one conveyor is replaced by two conveyors, the driving transmission mechanism includes a first screw conveyor 7 and a second screw conveyor 8, and the driving motor 4 drives the first screw conveyor 7 to drive the sawdust in the straw powder funnel 3 The straw powder and straw powder are transported to the trapezoidal funnel 2 to mix with feces, and the drive motor 4 drives the second screw conveyor 8 through the linkage mechanism 9 to discharge the straw powder and fecal mixture in the trapezoidal funnel 2 to the feces storage tank or septic tank. The straw powder funnel 3 is installed on the first screw conveyor 7, the first screw conveyor 7 is installed on the side of the trapezoidal funnel 2, and the second screw conveyor 8 is installed at the bottom of the trapezoidal funnel 2.

[0031] In this embodiment, the sawdust and straw powder are trans...

Embodiment 3

[0033] The difference technology of embodiment three compared with embodiment two is as follows:

[0034] The end of the Jiaolong-driven transmission mechanism transports the manure to the manure storage tank or septic tank through the manure outlet 5. Let the feces in the toilet be transported to the feces storage tank at the rear of the toilet house or the three-compartment harmless septic tank through the Jiaolong drive transmission mechanism, so as to isolate the toilet personnel from close contact with the excrement accumulated in the toilet when they urinate and defecate , urine, and odor sources, realize semi-automatic or electric automatic Jiaolong-driven transmission mechanism, and Jiaolong-driven transmission mechanism transports feces to the outdoor three-format harmless septic tank or composting septic tank separated by the wall of the toilet, and collects them regularly Clean up compost and retting manure for resource utilization.

[0035] The squatting pan 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com