Apparatus and method for cutting specific prepreg shape using ultrasonic cutter

A prepreg and ultrasonic technology, applied in metal processing and other directions, can solve problems such as inability to achieve full pavement, large strip width, and product performance that does not meet the requirements for use, and achieve the effects of lowering temperature, smoothing ports, and reducing resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

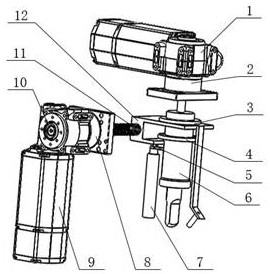

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] see figure 1 , the device provided by the present invention for cutting a specific prepreg shape using an ultrasonic cutter includes an ultrasonic cutter head 6, an ultrasonic cutter head clamp 12, a positioning sleeve 4, a positioning pin 5, a cylinder 7, a first drive motor 1, and a second Drive motor 9 and lead screw 11;

[0034] Wherein, the lead screw 11 is provided with an ultrasonic tool head clamp 12, and the ultrasonic tool head clamp 12 is provided with an ultrasonic tool head 6; the first driving motor 1 is connected with the ultrasonic tool head 6,

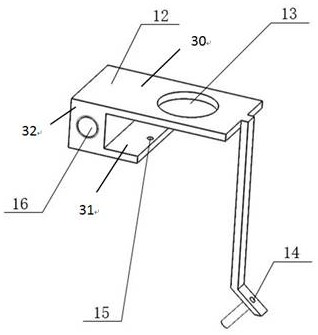

[0035] see figure 2 , the ultrasonic tool head clamp 12 includes a connecting plate 32, a top plate 30 is arranged on the top surface of the connecting plate 32, a bottom plate 31 is arranged on the bottom surface of the connecting plate 32, the length of the top plate 30 is greater than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com