The detection method based on the sheet material overrun detection device in front of the press line cleaning machine

A detection device and detection method technology, applied in the direction of cleaning methods and appliances, conveyor control devices, chemical instruments and methods, etc., can solve the problems of long production time, bending and folding of sheets, complex shapes and combinations thereof without suitable ultra-high technology Wide detection methods and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

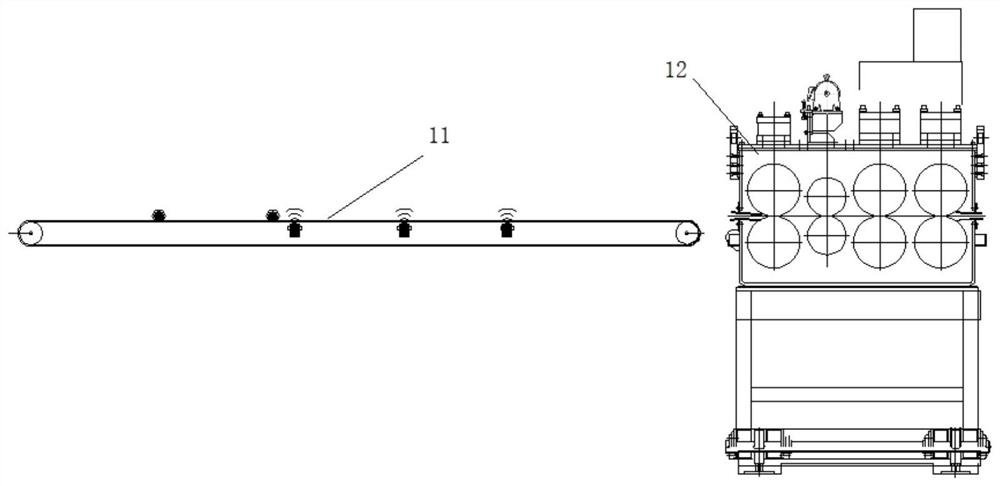

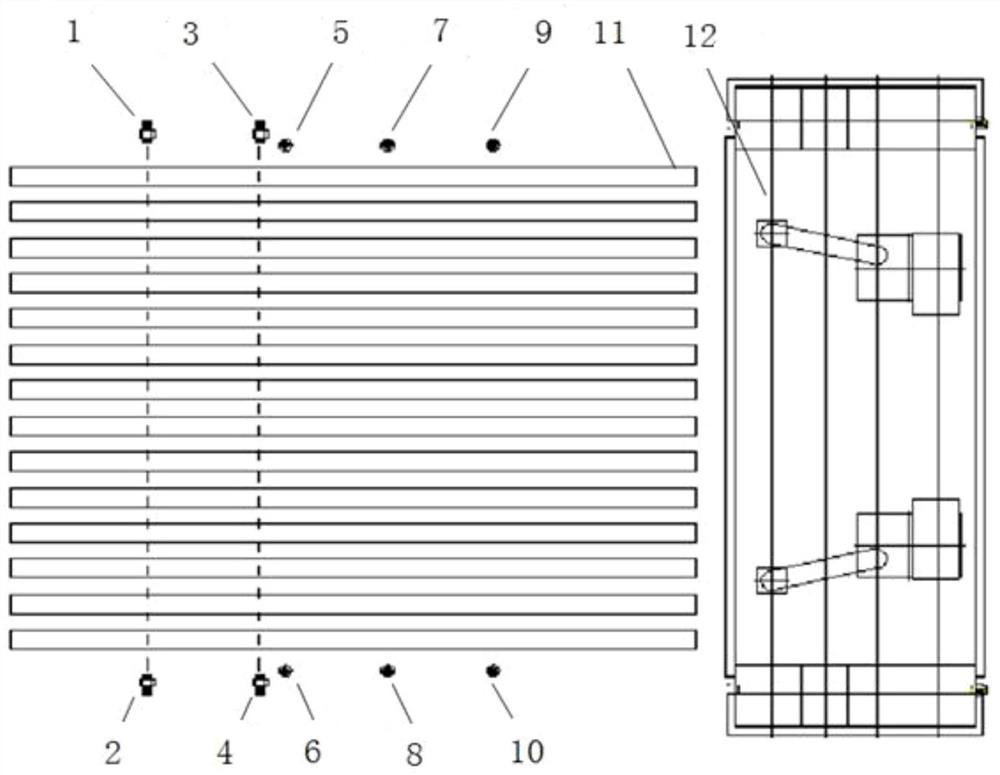

[0025] Such as Figure 1-2 As shown, the installation of the plate overrun detection device before the punching line cleaning machine of the present invention: the belt conveyor 11 and the cleaning machine 12 are installed on the ground, and the end of the normal conveying direction of the belt conveyor 11 is connected with the cleaning machine 12, and its The gap meets the passing requirements of the smallest sheet. The first panel detector 5 - the sixth panel detector 10 and the first group of through-beam detectors - the second group of through-beam detectors are respectively installed symmetrically on both sides of the belt conveyor 11 . The distance between the through-beam detectors in the vertical conveying direction is gr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap