Reinforcing structure and reinforcing method of old house

A technology for strengthening structures and houses, applied in building components, building structures, building maintenance, etc., can solve problems such as load-bearing performance reduction, wall damage and aging, house collapse, etc., and achieve the effect of increasing stability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

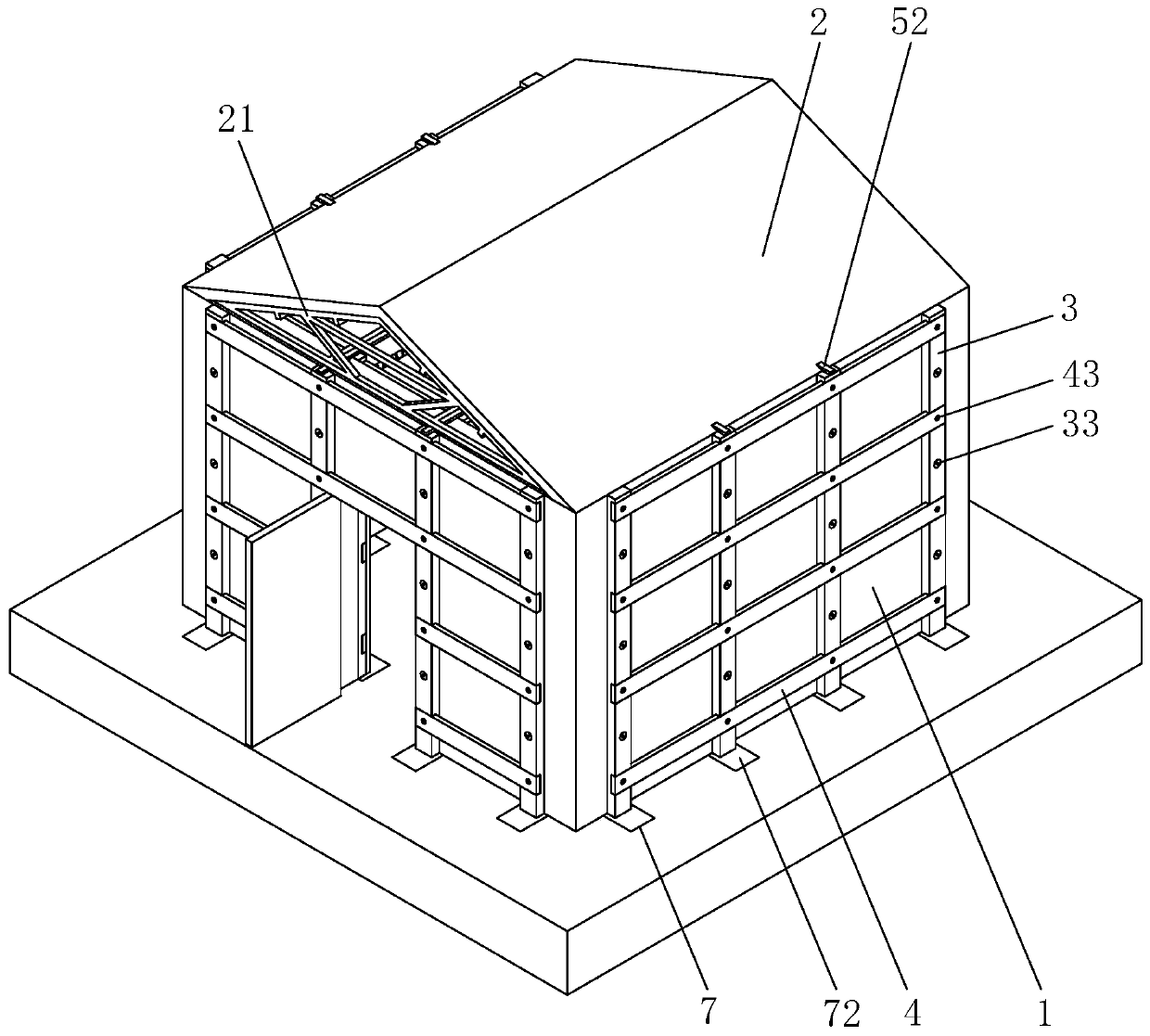

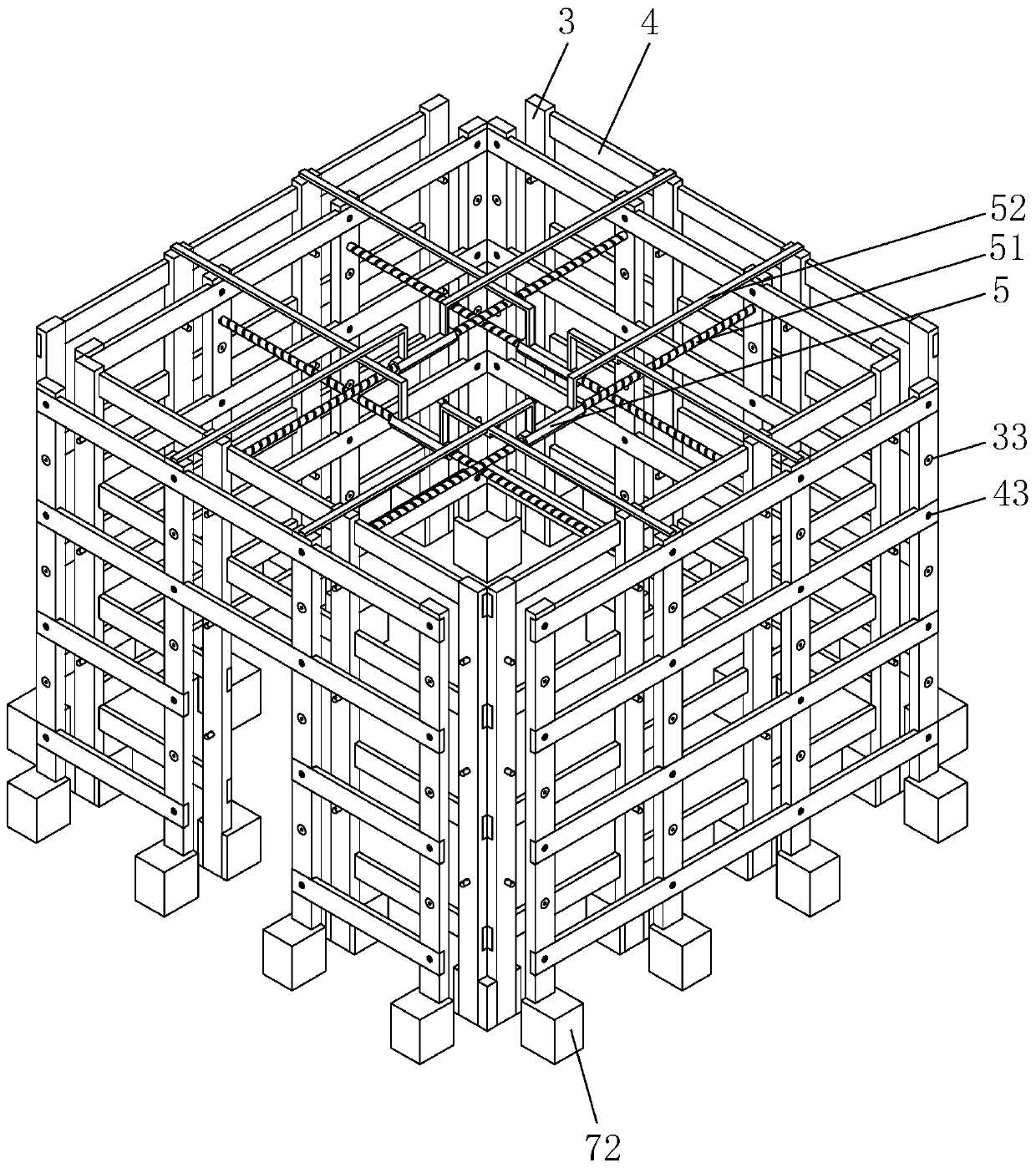

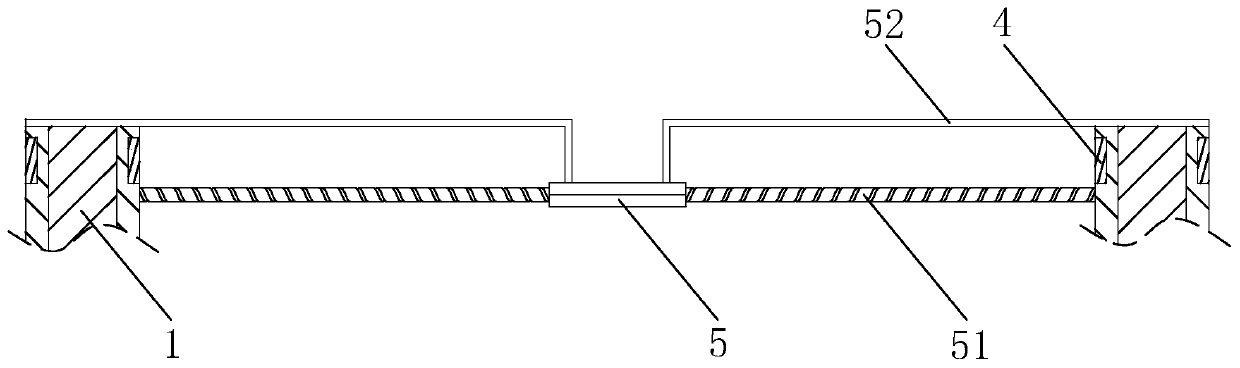

[0051] Reference figure 1 with figure 2 , Is the reinforcement structure of the old house disclosed in the present invention. The roof 2 is fixed above the four-sided wall 1, and the inner and outer side walls of the four-sided vertical wall 1 are parallel and abutted with a number of vertical reinforcing plates 3. In this embodiment There are four equally spaced vertical reinforcing plates 3 on the inside and outside of the same wall 1, and the vertical reinforcing plates 3 are opposite to each other inside and outside the wall 1, and the upper surface of the vertical reinforcing plate 3 is flush with the upper surface of the wall 1. The side walls of the vertical reinforcing plate 3 away from the wall 1 are horizontally fixed with a number of horizontal reinforcing plates 4. In this embodiment, the four vertical reinforcing plates 3 on the same side are fixed to four equally spaced horizontal reinforcing plates 4. Both the plate 3 and the horizontal reinforcement plate 4 are ...

Embodiment 2

[0058] A method for strengthening old houses, including the following steps:

[0059] S1. Use factory-produced prefabricated vertical reinforcement plates 3, horizontal reinforcement plates 4 and adjusting screw sleeves 5, so that the bottom end of the vertical reinforcement plate 3 is provided with a number of reinforcement steel bars 71, and the vertical reinforcement plate 3 is far away from the side wall of the wall 1. The clamping groove 31, the leveling groove 33, the threaded hole 32 and the insertion hole 34, the horizontal reinforcing plate 4 is away from the vertical reinforcing plate 3 and a number of containing grooves 43 and through holes 42 are opened. The adjustment screw sleeve 5 is determined according to the length of the house to be reinforced Production length

[0060] S2. Dig a number of insertion holes 7 at the bottom end of the wall 1, put the bottom end of the vertical reinforcement plate 3 and a number of reinforcing steel bars 71 into the insertion holes 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com