Vibration screening device

A technology of vibrating screen and sieve plate, applied in the direction of filter screen, solid separation, grille, etc., can solve problems such as inconvenience of use, and achieve the effects of convenient operation, prolonging service life and highlighting practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

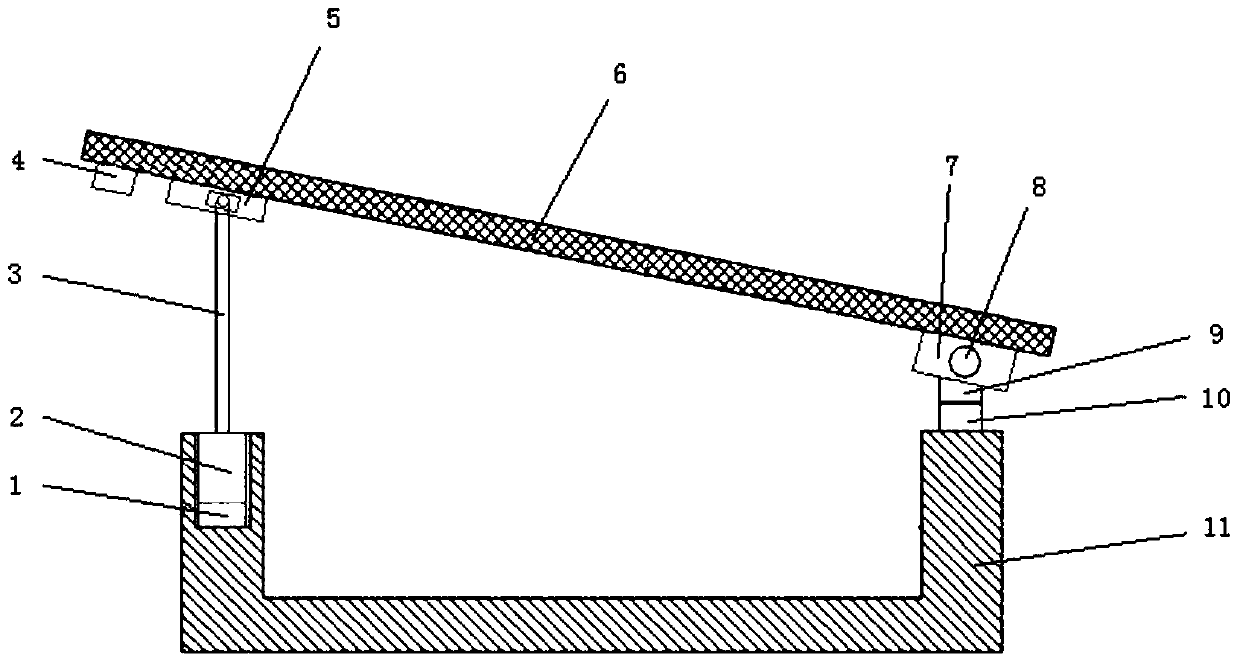

[0017] combine figure 1 As shown, a vibrating sieving device includes a hopper 11 and a sieve plate 6 placed directly above the opening of the hopper, the lower surface of one end of the sieve plate 6 is hinged on the edge of the side of the hopper 11, and the other end of the sieve plate 6 The lower surface of the bottom surface is placed on the edge of the other side of the material box 11 through the self-locking electric cylinder 2; between the sieve plate 6 and the material box 11, a pie between the base 7, the rotating shaft 8 with bearings and the vertical support column 9 is used. And to realize the hinge, the base 7 is placed on the lower surface of the sieve plate 6, the base 7 is provided with a groove for arranging the bearing and the rotating shaft 8, the lower end of the support column 9 is fixed on the side edge of the material box 11, and the upper end is fixed on the bearing on the shell; the body of the self-locking electric cylinder 2 is fixedly placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com