Welding machine with fixing device for truss production

A fixing device and welding machine technology, applied in the field of truss welding, can solve problems such as welding smoke, affecting welding quality, difficult to adjust flexibly, and achieve the effect of preventing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

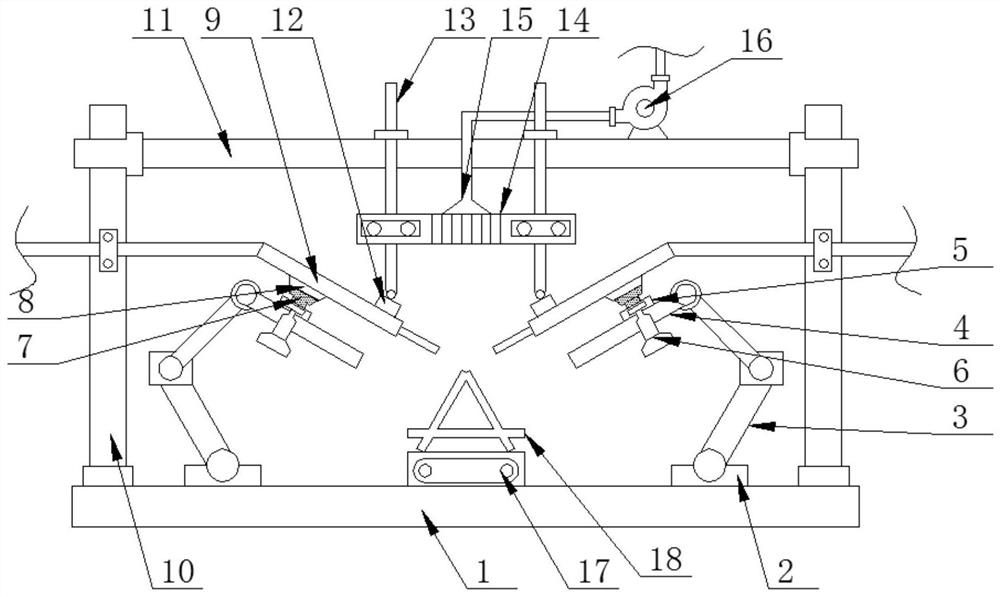

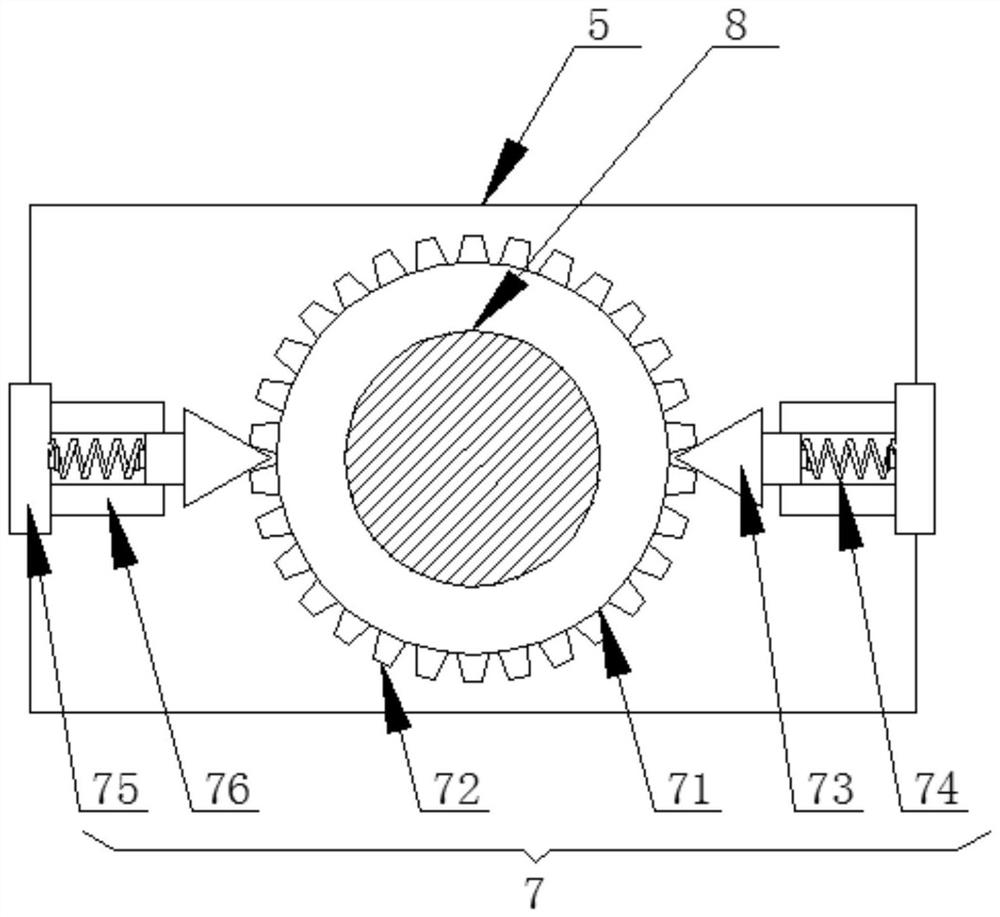

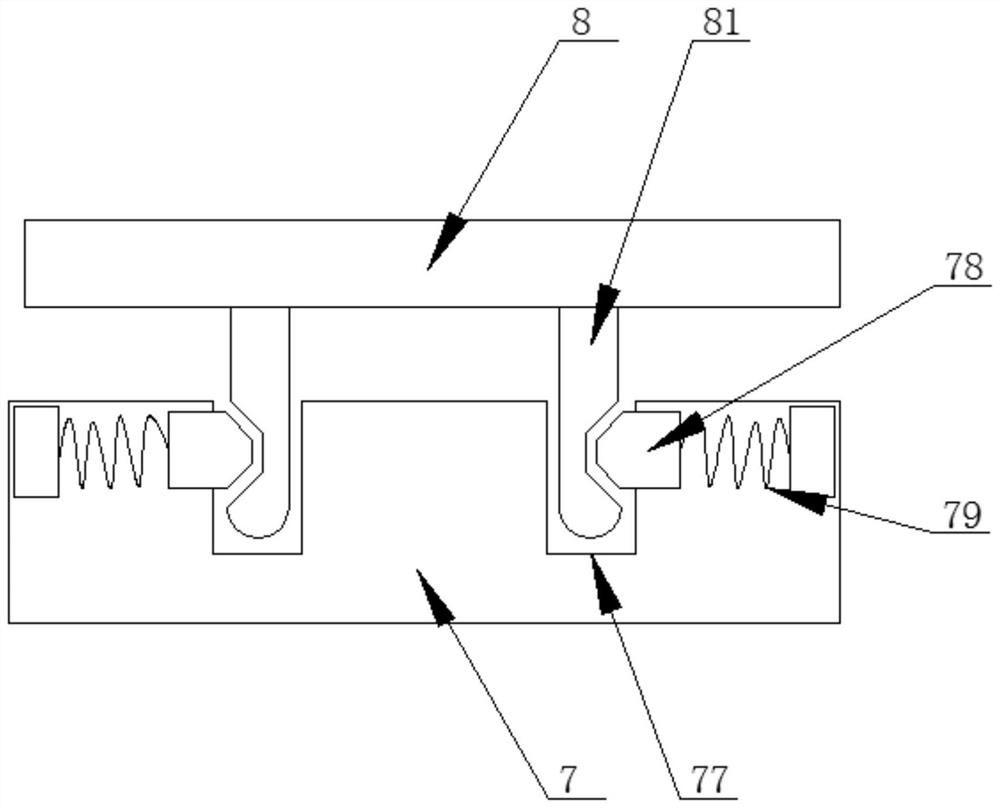

[0022] Embodiment: When in use, adjust the first mechanical arm 3 and the second mechanical arm 4 so that they fix the approximate position of the welding torch 9. After fixing, connect the connecting block 8 at the bottom of the welding torch 9 to the rotating device 7, and the rotating device 7 The round table 71 can be rotated on the turntable 5, so that the direction of the muzzle of the welding torch 9 can be adjusted by rotation, and the slide block 12 of the muzzle head slides on the front and rear guide rods 13, so that the position of the muzzle of the welding torch 9 is fixed. Rotate the bolt 6, and the bolt 6 is ejected from the turntable 5, so that the turntable 5 and the second mechanical arm 4 are separated from each other. Since the muzzle of the welding torch 9 is fixed by the mutual extrusion of the slider 12 and the front and rear guide rods 13, the welding torch 9 When the tail is raised, the direction of the muzzle can be fine-tuned, which is flexible and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com