Double-head shuttle printing machine

A shuttle-type printing machine technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of small glass screen size, many openings, low intelligence, etc., to speed up the printing cycle, fast delivery speed, printing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with accompanying drawing:

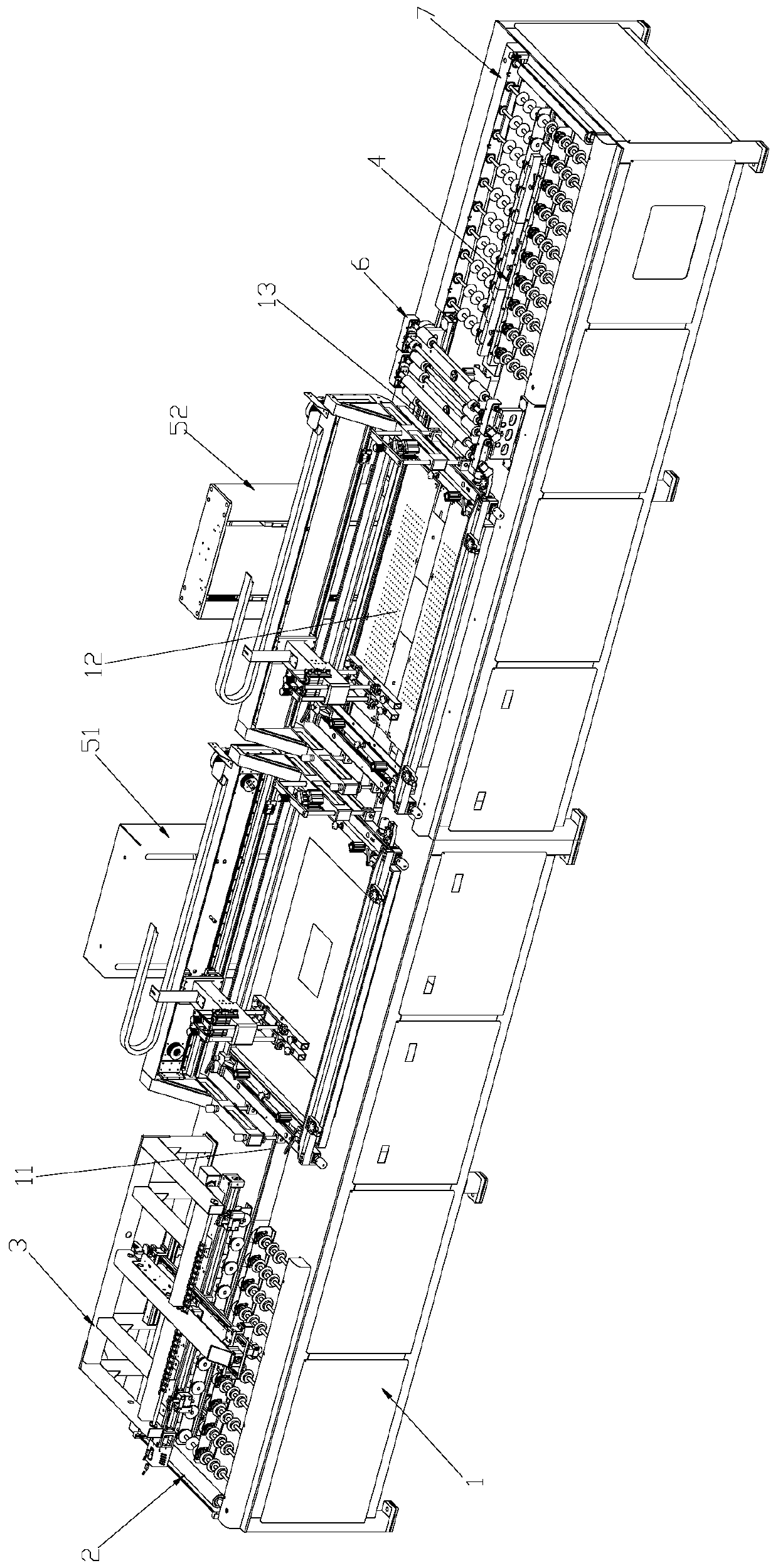

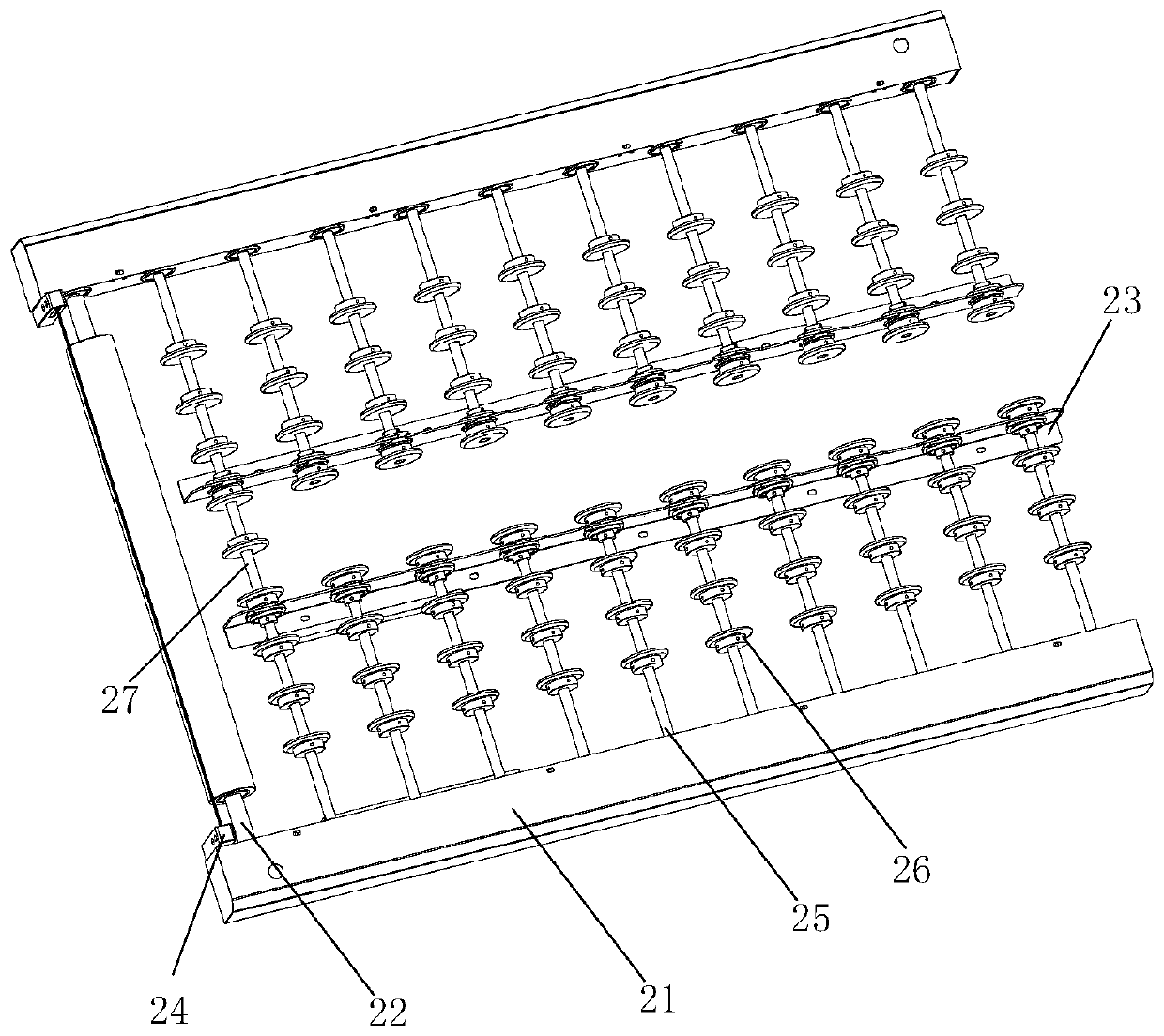

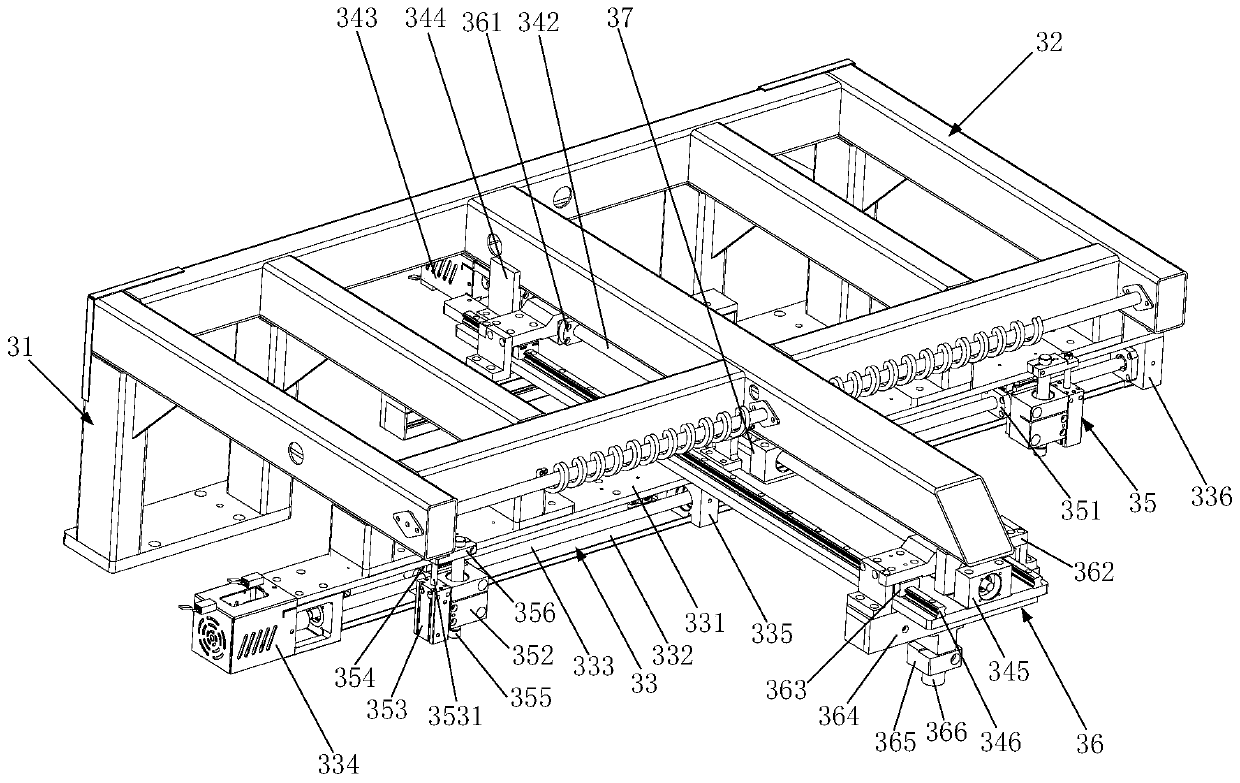

[0046] see figure 1 As shown, a double-head shuttle printing machine is characterized in that it includes two sections of frame 1 connected by taper pin plates, and the frame 1 is sequentially arranged with a feeding module 2 and a first printing platform module 51 , the second printing platform module 52, the wiping screen module 6, the discharging module 7, the initial positioning module 3 is also arranged above the described feeding module, and the initial positioning module 3 is fixed on the frame 1 through the initial positioning welding frame Above, the frame 1 connected by the conical pin plate is provided with an empty slot 11 along the longitudinal centerline, the shuttle module 4 is installed inside the frame 1 and runs through the entire frame 1 longitudinally, the supporting platform of the shuttle module 7 The component and the material discharge sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com