Flight control surface for aircraft, method for manufacturing flight control surface and aircraft

A technology for flight control surfaces and aircraft, applied in the field of flight control surfaces, can solve the problems of increasing weight and manufacturing time, and achieve the effects of saving weight, being less prone to breakage, and maintaining electrical continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

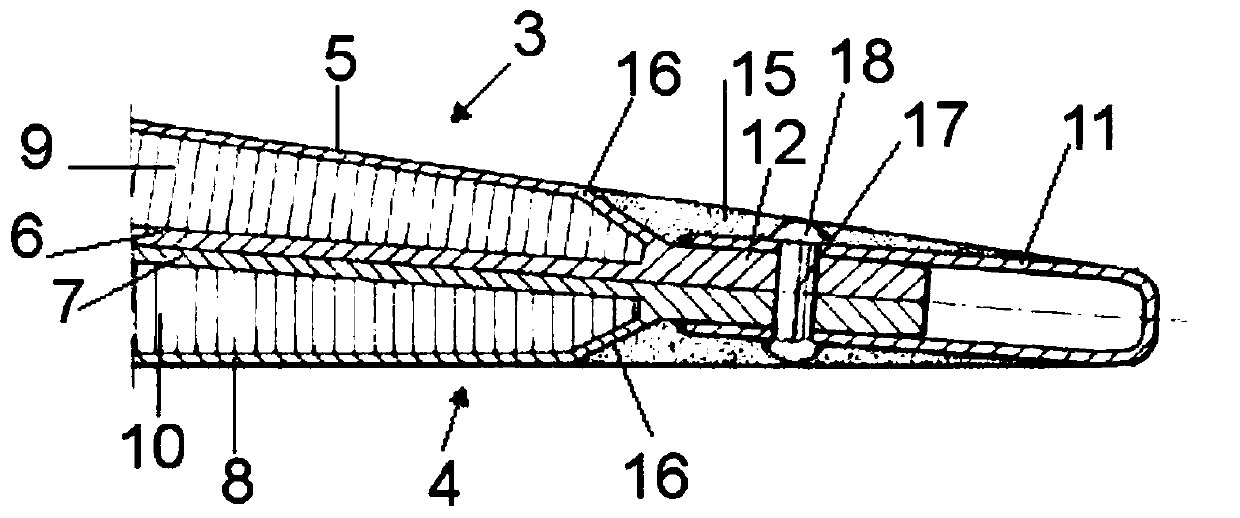

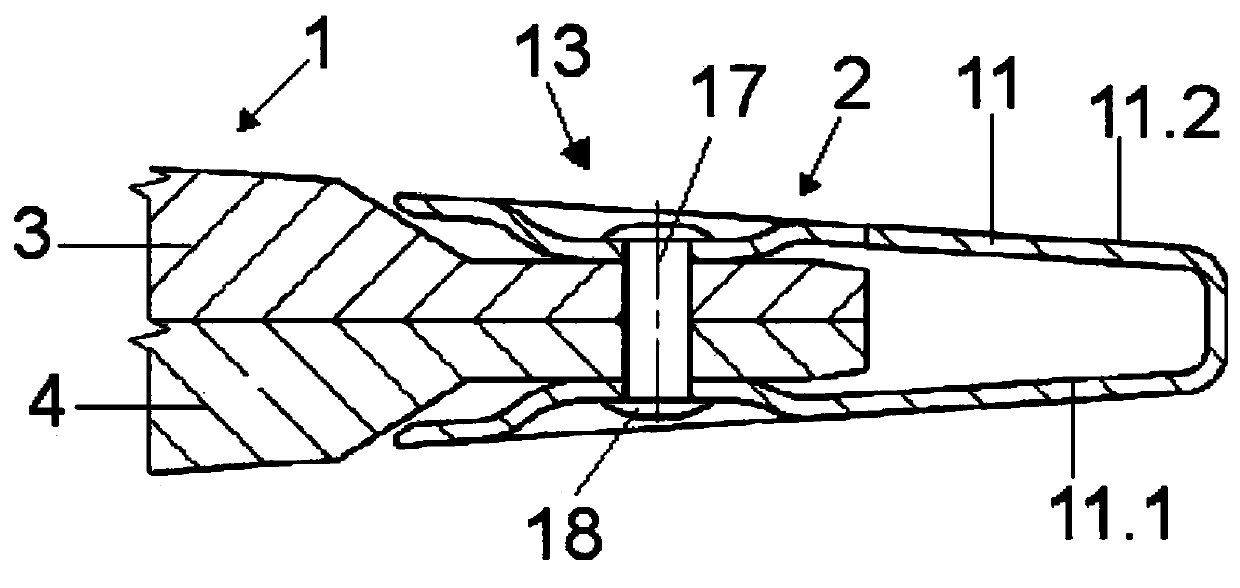

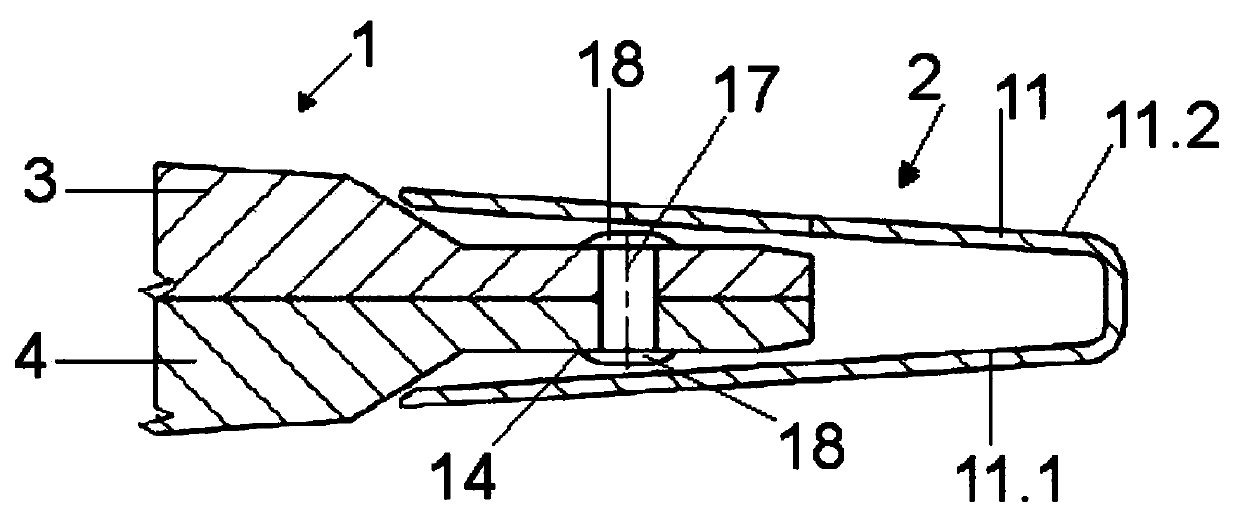

[0032] figure 1 A control surface according to the prior art is disclosed, wherein the body (1) is depicted as comprising an upper cover (3) and a lower cover (4), including an upper and a lower skin of each cover (3, 4) skins (5, 6, 7, 8), and upper and lower skins (5, 6, 7, 8) of each cover (3, 4) and core members (9, 10 ).

[0033] Furthermore, the skins (5, 6, 7, 8) of the covers (3, 4) comprise extensions (12) in their length which extend beyond the core member (9 , 10) Length. This extension (12) defines a stepped area (16) between areas of the main body (1) in which there are core members (9, 10) without core members in the extension (12) itself (9, 10).

[0034] figure 1 A U-shaped profile (11) enclosing an extension (12) of the main body (1) and a filler material (15) filling the gap between the stepped area (16) and the U-shaped profile (11) so as to achieve a smooth transition are disclosed . Another possibility known in the prior art would be to have U-shape...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap