Automatic packaging and bundling device suitable for grapefruits of multiple specifications

A technology with multiple specifications and pomelo, which is applied in packaging, transportation packaging, and food packaging, etc., can solve the problems of high labor costs, shortage of labor in pomelo production areas, and high difficulty, so as to improve product aesthetics and standardization, and reduce packaging labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with reference to the accompanying drawings:

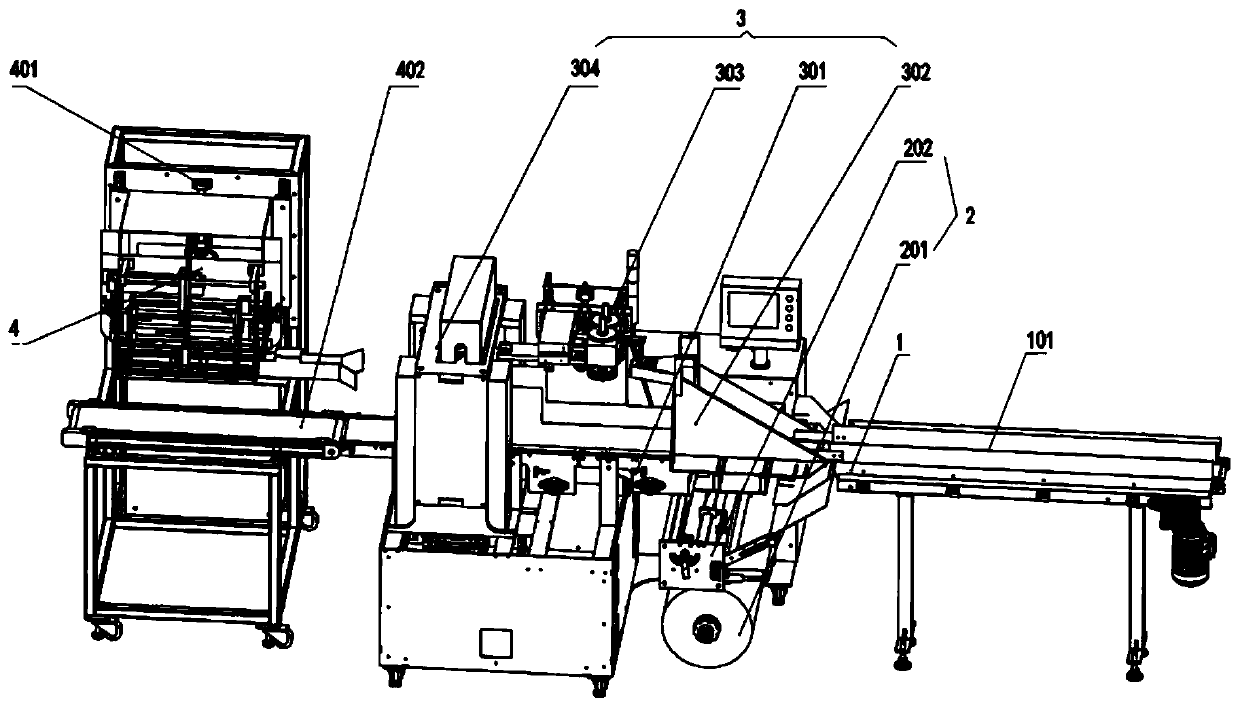

[0039] refer to Figure 1-7 , an automatic bag tying device adapted to multiple specifications of grapefruit, including:

[0040] Feeding mechanism 1, including a first conveyor belt 101 for power transmission of pomelo;

[0041] The film discharge mechanism 2 is arranged below the discharge end of the feeding mechanism 1, and the film discharge mechanism 2 includes:

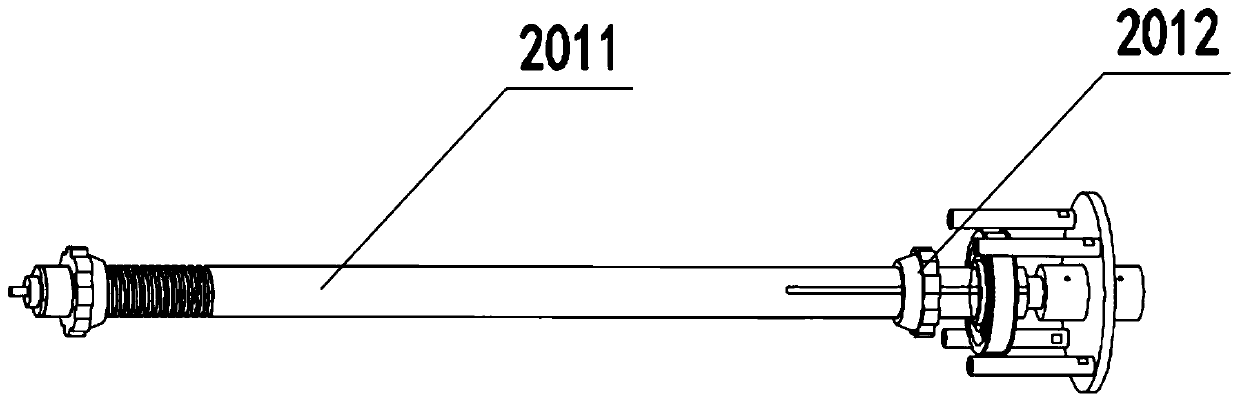

[0042] A roll-to-roll film unwinding mechanism 201, and

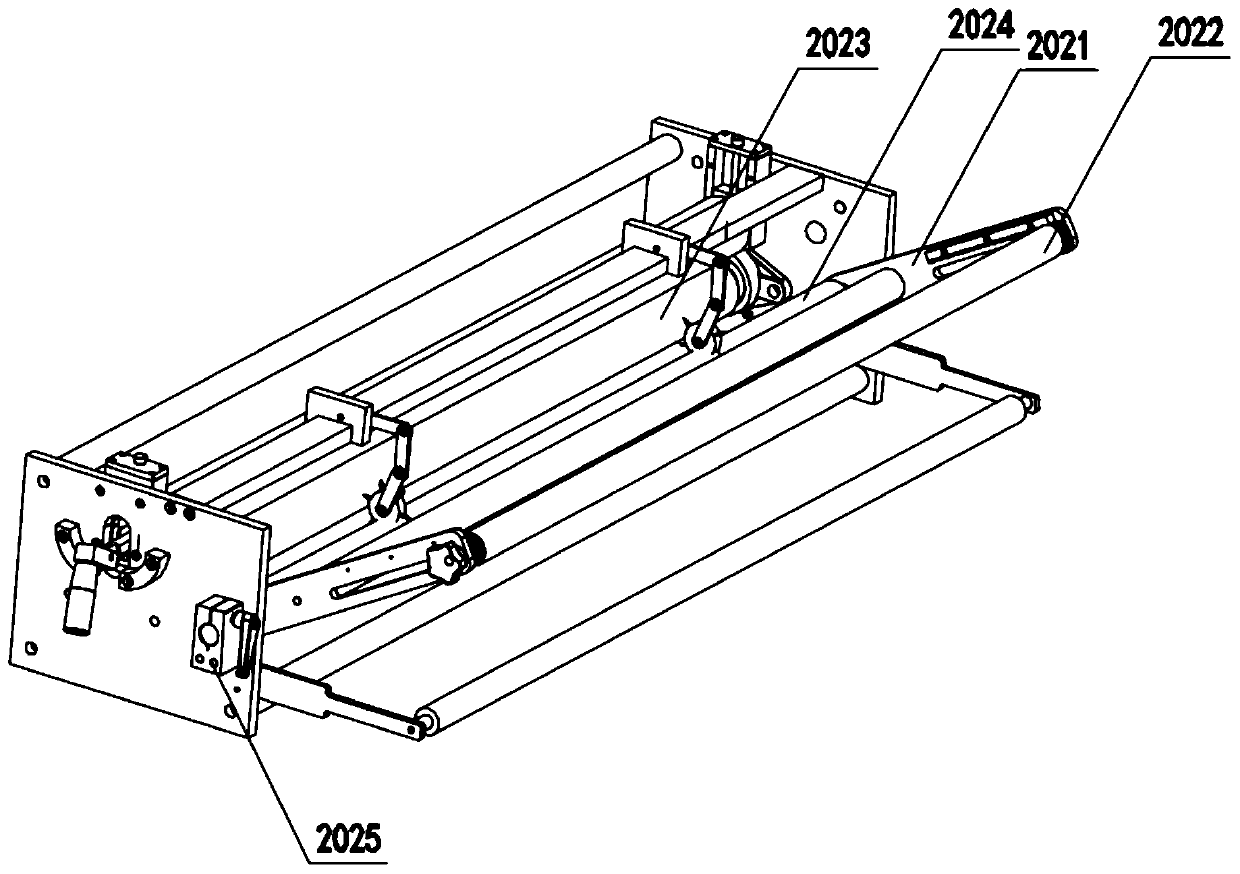

[0043] An active film conveying mechanism 202, the active film conveying mechanism 202 includes a first rotating motor for providing power, the active film conveying mechanism 202 is provided with a swing rod 2021, and the swing rod 2021 is installed with a film guide roller 2022, The swing rod 2021 is arranged obliquely upward to guide the packaging film t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com