pre-processing trash can

A garbage can and pretreatment technology, applied in the field of garbage cans, can solve the problems of small amount of garbage stored in the garbage can, shoes sticking to garbage, occupying a large space, etc., and achieve the effect of simple operation, good economy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

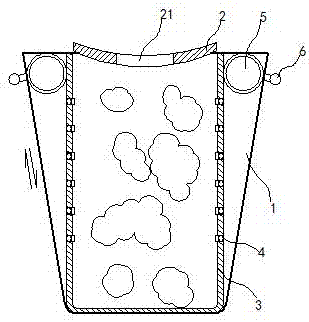

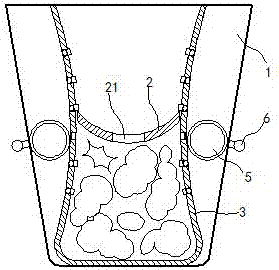

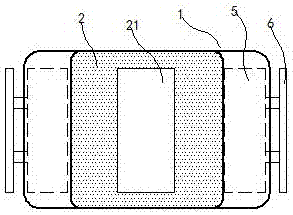

[0018] exist Figure 1 to Figure 4 In the shown embodiment, the pretreatment trash can includes a shell 1 and a cover 2; the cover 2 is made of elastic ferromagnetic material, such as a ferromagnetic sheet; the cover 2 is downward A curved arc, and an input port 21 is opened on the cover body 2;

[0019] The housing 1 is in the shape of a trapezoidal cylinder with a large top and a small bottom; an inner tank 3 is installed inside the housing 1, and the inner tank 3 is straight, and the bottom of the inner tank 3 matches the size of the bottom of the housing ;

[0020] The inner container 3 is made of elastic plates; on the inner surface of the inner container 3, magnetic force limit buttons 4 are arranged in an equidistant array from bottom to top; in this embodiment, the magnetic force limit buttons 4 It includes a chute 41, an elastic block 42 and a limit block 43, the limit block 43 is made of ferromagnetic material; the opening direction of the chute 41 is perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com