Crawler-type conveyor

A belt conveyor and conveyor technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as affecting project operation, inability to move normally, and low relocation efficiency, and achieve intelligent operation. , The effect of convenient and quick disassembly and assembly, and long conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

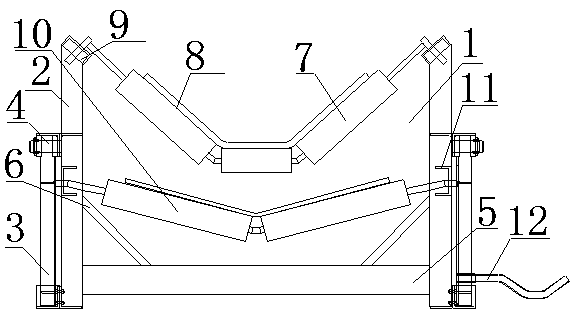

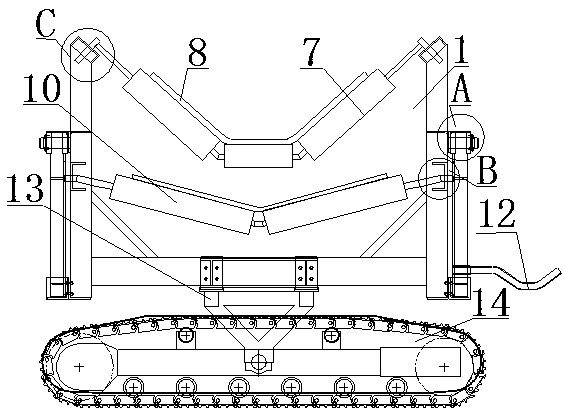

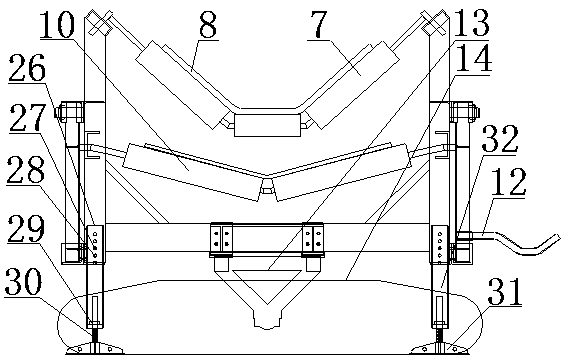

[0026] Such as Figure 1-11As shown, a crawler conveyor includes a belt conveyor 1 and a crawler running mechanism 14. The left and right sides of the belt conveyor 1 are provided with profiled side plates 2, and the pressurized side plates 2 on both sides of the described The top of the type side plate 2 is provided with a corresponding upper hanging mechanism 9, and an upper hanging idler group 7 is arranged between the upper hanging mechanisms 9, and both ends of the upper hanging idler group 7 pass through locking screw rods 37 Fixed on the corresponding upper hanging mechanism 9, the upper surface of the upper hanging roller group 7 is provided with an adhesive tape 8, and the inner middle of the profiled side panels 2 on both sides is provided with a lower hanging mechanism 11, so The lower hanging idlers 10 are arranged between the lower hanging mechanisms 11, and the two ends of the lower hanging idlers 10 are fixed on the profiled side plate 2 through the lower hangin...

Embodiment 2

[0035] Such as Figure 1-11 As shown, a crawler conveyor includes a belt conveyor 1 and a crawler running mechanism 14. The left and right sides of the belt conveyor 1 are provided with profiled side plates 2, and the pressurized side plates 2 on both sides of the described The top of the type side plate 2 is provided with a corresponding upper hanging mechanism 9, and an upper hanging idler group 7 is arranged between the upper hanging mechanisms 9, and both ends of the upper hanging idler group 7 pass through locking screw rods 37 Fixed on the corresponding upper hanging mechanism 9, the upper surface of the upper hanging roller group 7 is provided with an adhesive tape 8, and the inner middle of the profiled side panels 2 on both sides is provided with a lower hanging mechanism 11, so The lower hanging idlers 10 are arranged between the lower hanging mechanisms 11, and the two ends of the lower hanging idlers 10 are fixed on the profiled side plate 2 through the lower hangi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com